Ford Mustang (1999-2004) Service Manual: Removal

1. Remove the differential assembly from the differential housing. For additional information, refer to Differential Case in this section.

2. CAUTION: Record the torque necessary to maintain rotation of the drive pinion gear through several revolutions prior to removing the pinion flange (4851).

Remove the pinion flange. For additional information, refer to Drive Pinion Flange and Drive Pinion Seal in this section.

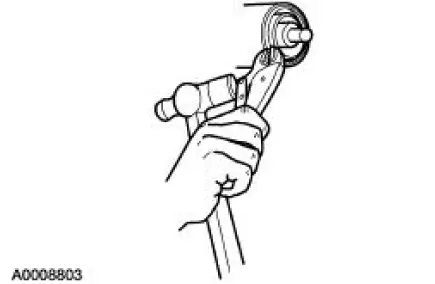

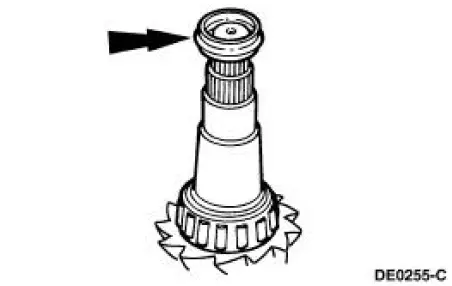

3. Force the rear axle drive pinion seal metal flange up. Install gripping pliers and strike with a hammer to remove the seal.

4. Remove the rear axle drive pinion shaft oil slinger (4670).

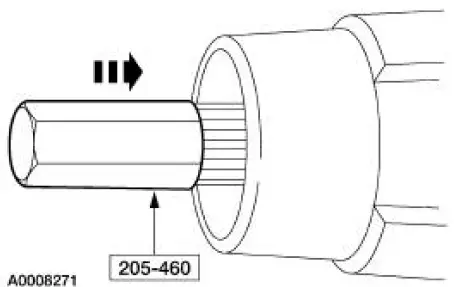

5. Using the special tool and a soft-faced hammer, drive the pinion assembly out of the outer differential pinion bearing (4621) and remove the drive pinion through the rear of the differential housing (4010).

6. Remove the outer differential pinion bearing.

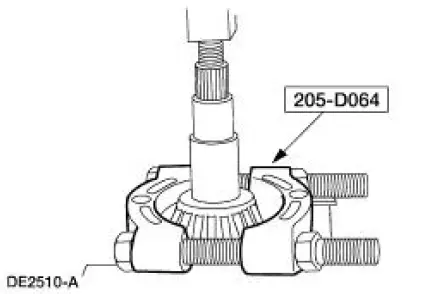

7. Remove and discard the collapsible spacer (4662).

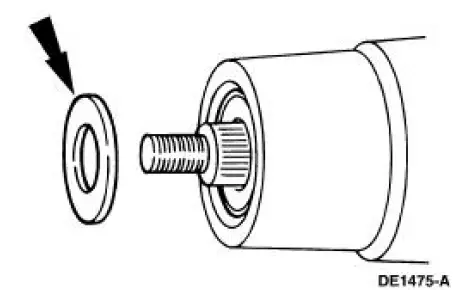

8. Using the special tool and a suitable press, remove the inner differential pinion bearing (4630).

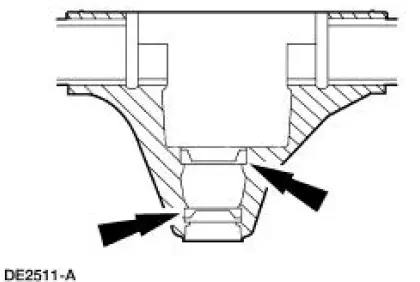

9. NOTE: Do not remove the pinion bearing cups from the differential housing unless the cups are damaged.

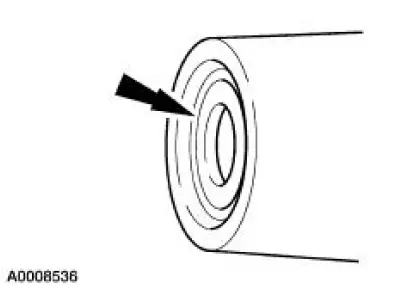

To remove the bearing cups, tap alternately (with a brass drift of suitable length) on opposite sides of the cup to prevent the cup from cocking in the casting.

Drive Pinion

Drive Pinion

Special Tool(s)

Adapter for 205-S127

205-105 (T76P-4020-A3)

Adapter for 205-S127

205-109 (T76P-4020-A9)

Adapter for 205-S127

205-110 (T76P-4020-A10)

Adapter fo ...

Installation

Installation

Using special tool 205-054

NOTE: This is the preferred method for installing the pinion bearing

cups. If necessary, proceed to

Using special tools 205-153, 205-054, and 205-D055 in this procedure for ...

Other materials:

General information

Make sure you review your device’s manual before using it with SYNC.

Support

The SYNC support team is available to help you with any questions you

cannot answer on your own.

Monday-Saturday, 8:30am-9:00pm EST.

Sunday, 10:30am-7:30pm EST.

In the United St ...

Installation

1. Lubricate the lip of the wheel bearing oil seal

Use Premium Long-Life Grease XG-1-C or equivalent meeting Ford

specification ESAM1C75-

B.

2. CAUTION: Do not damage the wheel bearing oil seal.

Install the two axle shafts.

3. CAUTION: Do not damage th ...

Pinpoint Test L: B1892 - Air Bag Tone Warning Indicator Circuit Shorted to

Ground or Open

Normal Operation

The restraints control module (RCM) monitors its connection to the

generic electronic module (GEM) at

C201e pin 10. This connection is used to signal a chime if the air bag

indicator is inoperative and

another SRS fault exists. If the R ...