Ford Mustang (1999-2004) Service Manual: Removal

1. Remove the differential assembly from the differential housing. For additional information, refer to Differential Case in this section.

2. CAUTION: Record the torque necessary to maintain rotation of the drive pinion gear through several revolutions prior to removing the pinion flange (4851).

Remove the pinion flange. For additional information, refer to Drive Pinion Flange and Drive Pinion Seal in this section.

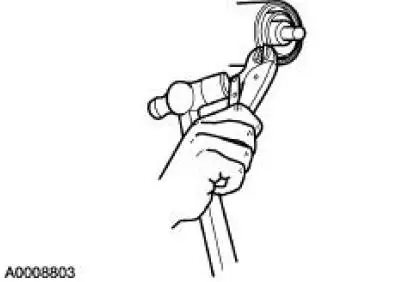

3. Force the rear axle drive pinion seal metal flange up. Install gripping pliers and strike with a hammer to remove the seal.

4. Remove the rear axle drive pinion shaft oil slinger (4670).

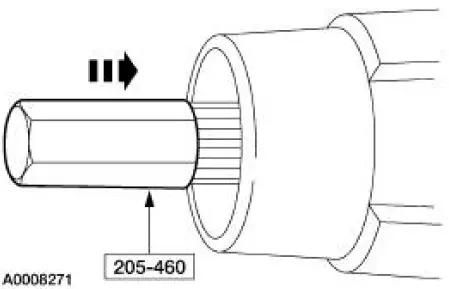

5. Using the special tool and a soft-faced hammer, drive the pinion assembly out of the outer differential pinion bearing (4621) and remove the drive pinion through the rear of the differential housing (4010).

6. Remove the outer differential pinion bearing.

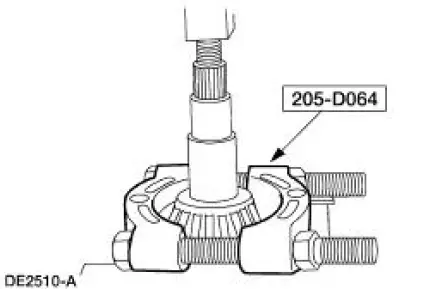

7. Remove and discard the collapsible spacer (4662).

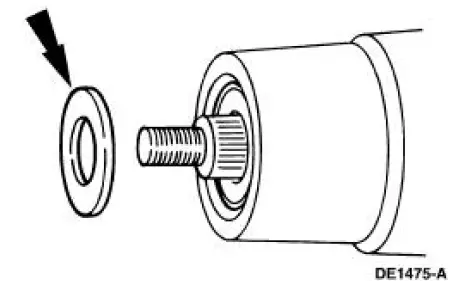

8. Using the special tool and a suitable press, remove the inner differential pinion bearing (4630).

9. NOTE: Do not remove the pinion bearing cups from the differential housing unless the cups are damaged.

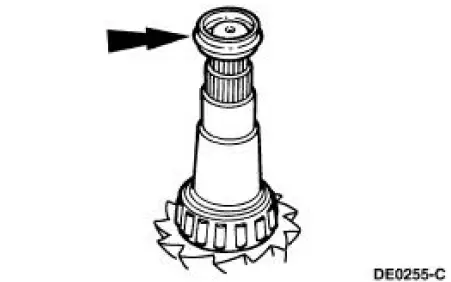

Using the special tools, remove the outer differential drive pinion bearing cup (4616).

10. Using the special tools, remove the inner rear axle pinion bearing cup (4628).

Drive Pinion

Drive Pinion

Special Tool(s)

Adapter for 205-S127

205-105 (T76P-4020-A3)

Adapter for 205-S127

205-109 (T76P-4020-A9)

Adapter for 205-S127

205-110 (T76P-4020-A10)

Adapter fo ...

Installation

Installation

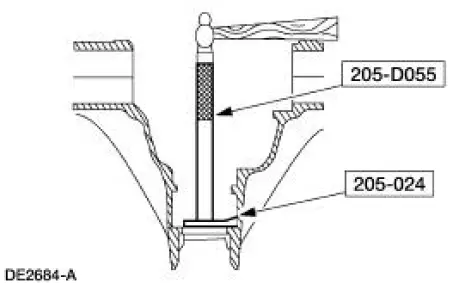

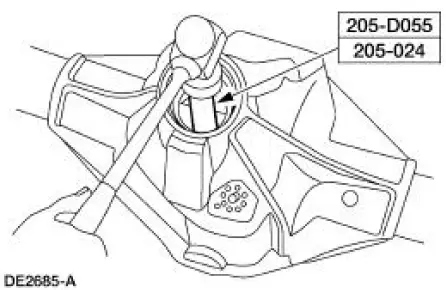

Using special tool 205-024

NOTE: This is the preferred method for installing the pinion bearing

cups. If necessary, proceed to

Using special tools 205-153, 205-024, 205-231, and 205-D055 in this proc ...

Other materials:

Diagnostic Trouble Code Charts

Diagnostic Trouble Code Chart

Five

Digit

DTC

Component

Description

Condition

Symptom

Action

P0102

P0103

P1100

P1101

MAF

MAF concerns

MAF system has a

malfunction which

may cause a

transmission

concern.

High or low ...

Lamp Assembly - Map/Dome

Removal

1. Disconnect the battery ground cable.

2. Remove the lamp lens from the lamp assembly.

3. Remove the lamp assembly.

1. Remove the screws.

2. Remove the lamp assembly.

Disconnect the electrical connectors.

Installation

1. NOTE ...

Essential towing checks

Follow these guidelines for safe towing:

• Do not tow a trailer until you drive your vehicle at least 1000 miles

(1600 kilometers).

• Consult your local motor vehicle laws for towing a trailer.

• See the instructions included with towing accessories for ...