Ford Mustang (1999-2004) Service Manual: Switch - Horn

Removal

1. Remove the driver side air bag module (043B13). Refer to Section.

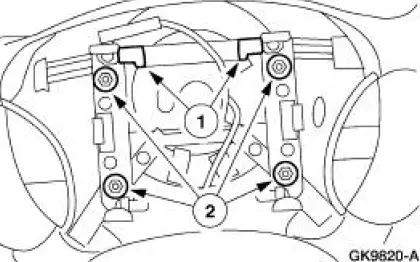

2. Remove the switches.

1. Disconnect the horn wire from the switches.

2. Remove the horn switch screws and remove the switches.

Installation

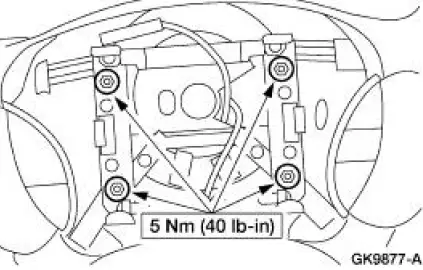

1. To install, reverse the removal procedure.

- Prove out the air bag system. Refer to Section.

Horn (Diagnosis and Testing)

Horn (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 44 , Horns/Cigar Lighter for schematic

and connector information.

Special Tool(s)

73 Digital Multimeter or

equivalent

105-R0051

Inspection and Veri ...

Warning Devices

Warning Devices

Warning Devices

The warning device system consists of the following components:

door ajar switches

generic electronic module (GEM)

key-in-ignition warning switch

safety belt switch

...

Other materials:

Connecting Rod - Bushing Diameter

1. Measure the inner diameter of the connecting rod bushing, if equipped.

Verify the diameter is

within specification.

Refer to the appropriate section in Group for the procedure.

If out of specification, install new components as necessary. Refer

...

The better business bureau (BBB) auto line program

(U.S. Only)

Your satisfaction is important to Ford Motor Company and to your dealer.

If a warranty concern has not been resolved using the three-step

procedure outlined earlier in this chapter in the Getting the Services

You Need section, you may be eligible to participa ...

Installation

1. CAUTION: To prevent refrigerant system contamination, do not allow

dirt or other

foreign materials to enter the A/C compressor.

Clean the A/C compressor nose area.

2. Place the shaft seal on the special tool. Lubricate the shaft seal and the

special tool ...