Ford Mustang (1999-2004) Service Manual: Torque Converter Turbine to Pump Stator Interference Check

1. NOTE: Front pump support may remain in front pump support and gear during this test.

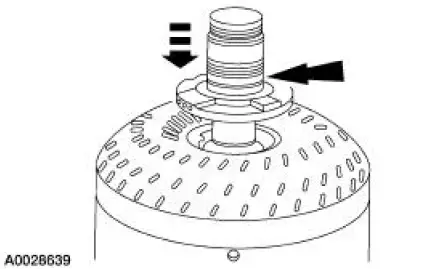

Position the torque converter with the pump drive up.

2. Install the front pump support to engage the mating splines of the front pump support shaft on the torque converter.

3. Install the forward clutch cylinder and shaft, engaging the splines with the rear clutch hub.

4. Check for stator to turbine interference.

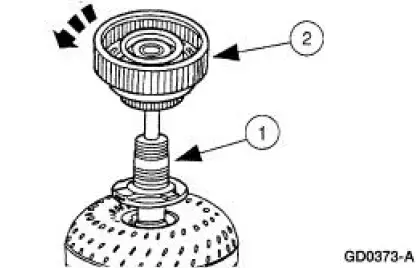

1. Hold the front pump support stationary.

2. Attempt to rotate the forward clutch cylinder and shaft.

- The turbine and torque converter clutch assemblies should rotate in both directions, not exceeding maximum torque of 9.5 Nm (7 lb-ft), without any signs of metallic interference or scraping noise.

5. If interference exists, the stator front thrust washer may be worn, allowing the stator to hit the turbine. In such cases, a new or remanufactured torque converter must be installed.

- The converter crankshaft pilot should be checked for nicks or damaged surfaces that could cause interference when installing the torque converter into the crankshaft. Check the converter front impeller hub for nicks or sharp edges that would damage the pump seal.

Torque Converter End Play Check

Torque Converter End Play Check

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

End Play Gauge, Torque

Converter

307-071 (T80L-7902-A) or

equivalent

...

Transmission (ASSEMBLY)

Transmission (ASSEMBLY)

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C)

Rubber Tip Air Nozzle

100-D009 (D93L-7000-A)

Alignment Gauge, TR Sensor

307-3 ...

Other materials:

Tracer Dye Leak Detection

Special Tool(s)

120 Watt 110 Volt UV Lamp

20C

164-R0721 or equivalent

NOTE: Ford Motor Company vehicles are produced with a permanent leak

tracer dye incorporated into

the A/C system. The location of leaks can be pinpointed by the bright

ye ...

Axle Housing Casting Porosity (Holes in Casting) Repair

CAUTION: To keep the axle's sound characteristics, do not disassemble

the carrier.

NOTE: Casting porosity is a condition where occasionally gas bubbles will

form during the casting

process leaving small pockets in the metal that will cause the axle housing t ...

Fuel Pump Module

Removal and Installation

1. Remove the fuel tank. For additional information, refer to Fuel Tank in

this section.

2. NOTE: For installation, tighten the bolts in the sequence shown.

Remove the module assembly flange bolts.

3. Clean the area around the fue ...