Ford Mustang (1999-2004) Service Manual: Transmission Case

Special Tool(s)

|

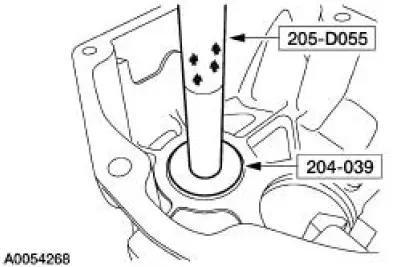

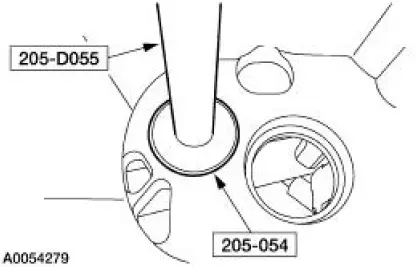

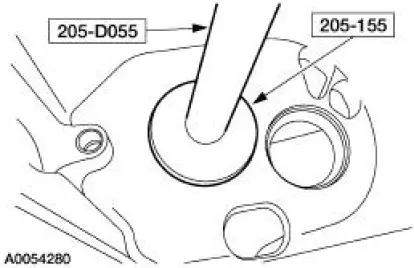

Handle 205-D055 (D81L-4000-A) |

|

Installer, Bearing Cup 204-039 (T77F-1217-B) |

|

Installer, Drive Pinion Bearing Cup 205-054 (T71P-4616-A) |

|

Installer, Rear Axle Oil Seal 205-155 (T80T-4000-Y) |

Disassembly and Assembly

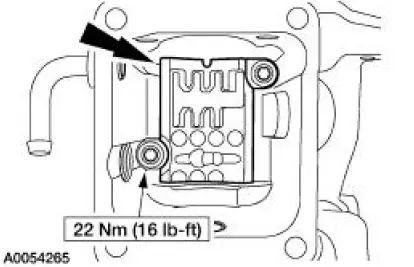

1. Remove the bolts and the guide plate.

- Inspect the plate for wear or damage. Install a new plate as necessary.

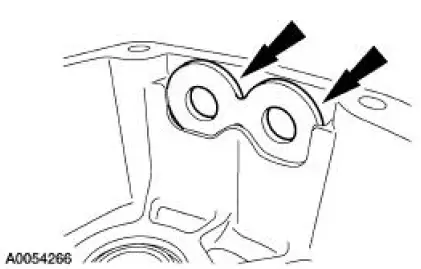

2. Remove the case magnets.

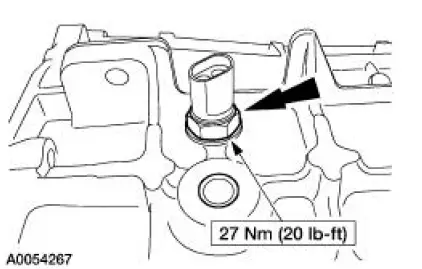

3. Remove the reverse lamp switch.

4. Using the special tools, remove the countershaft bearing cup.

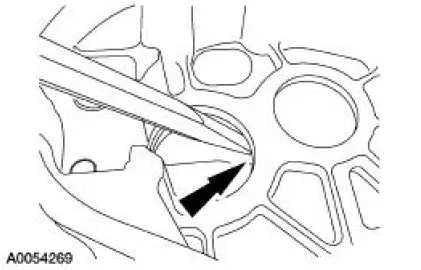

5. Using a brass drift, remove mainshaft bearing cup.

6. Inspect the countershaft and mainshaft bearing cups for wear or damage. Install new components as necessary.

7. WARNING: Make sure protective eye wear is in place.

Clean the case with solvent and dry with compressed air. Clean and check the sealing surface for nicks or scratches. Inspect the case for cracks.

- If the case is cracked, install a new case. If the sealing surface has nicks or scratches, use a soft stone or crocus cloth to remove.

8. NOTE: If a new countershaft bearing is being installed, install a new bearing cup. Always install new bearings and cups in a set.

Using the special tools, install the countershaft bearing cup.

9. NOTE: If a new mainshaft bearing is being installed, install a new bearing cup. Always install new bearings and cups in a set.

Using the special tools, install the mainshaft bearing cup.

10. To assemble, reverse the disassembly procedure.

Extension Housing

Extension Housing

Special Tool(s)

Installer, Bearing Cup

204-039 (T77F-1217-B)

Adapter for 303-224 (Handle)

205-153 (T80T-4000-W)

Disassembly and Assembly

1. Remove the bolt and ...

Transmission (Assembly)

Transmission (Assembly)

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Holding Fixture, Transmission

307-003 (T57L-500-B)

Remover/Inst ...

Other materials:

Air Bag Supplemental Restraint System (SRS) (Description and Operation)

The air bag supplemental restraint system (SRS) is designed to provide

increased collision protection

for front seat occupants in addition to that provided by the three-point safety

belt system. Safety belt

use is necessary to obtain the best occupant protec ...

Glass, Frames and Mechanisms

WINDOW REGULATOR ELECTRIC DRIVE

CURRENT DRAW

General Specifications

Torque Specifications

...

Pinpoint Test B: LFC 21/DTC B1921 - RCM Bracket Ground Resistance High

Normal Operation

WARNING: The tightening torque of the restraints control module

(RCM) retaining bolts is

critical for proper air bag supplemental restraint system (SRS)

operation. Refer to Restraints

Control Module (RCM) in this section for correc ...