Ford Mustang (1999-2004) Service Manual: Wiper Blade and Pivot Arm Adjustment

1. Cycle and park the windshield wipers.

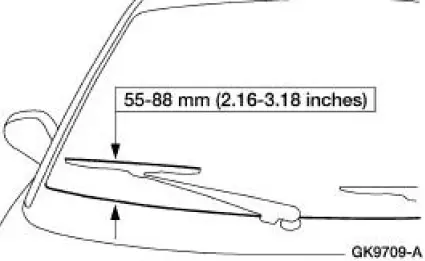

2. Verify that the distance between the center of the RH windshield wiper blade and the top edge of the cowl top vent panel is within specification.

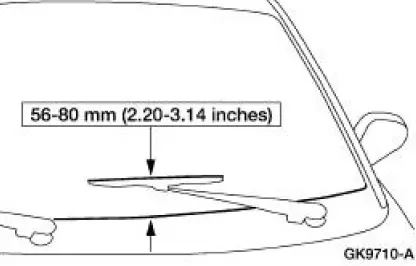

3. Verify that the distance between the center of the LH windshield wiper blade and the top edge of the cowl top vent panel is within specification.

4. If the distance is not within specification, remove the windshield wiper pivot arms and reposition to specification.

Remove the pivot arm.

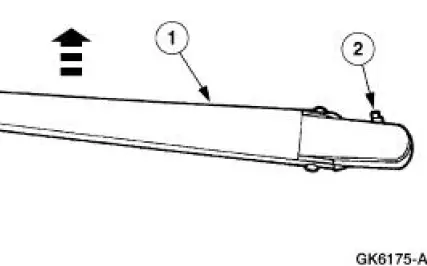

1. Pull up on the pivot arm.

2. Pull out on the retainer tab and remove the pivot arm.

Pivot Arm

Removal

1. NOTE: New windshield wiper pivot arms need to be installed as an assembly.

Remove the pivot arm.

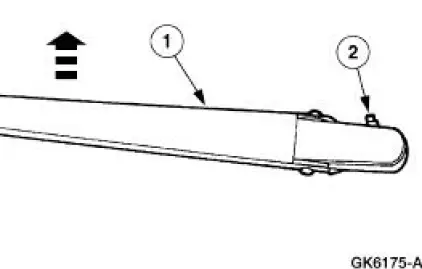

1. Pull up on the pivot arm.

2. Pull out on the retainer tab and remove the pivot arm.

Installation

1. To install, reverse the removal procedure.

Component Test

Component Test

Windshield Wiper Motor

CAUTION: Do not handle the wiper motor abusively when

diagnosing the wiper

operations. Failure to follow this caution may result in damage to the

motor magnets and wil ...

Mounting Arm and Pivot Shaft

Mounting Arm and Pivot Shaft

Removal

1. Park the windshield wipers in the full upright position. This will

allow for easy access to the

retaining clip on the wiper motor output shaft.

2. Remove the cowl top vent panels.

...

Other materials:

Column

Removal and Installation

All vehicles

1. Disconnect the battery ground cable and wait at least one minute to allow

the depletion of the

restraint system backup power supply.

2. WARNING: To avoid the risk of serious personal injury, follow all

warnings,

c ...

Starter Motor - 3.8L

Removal

WARNING: When servicing starter motor (11002) or carrying out other

underhood work in

the vicinity of the starter motor, be aware that the heavy gauge battery

input lead at the starter

solenoid (11390) is "electrically hot" at all times. A prote ...

Driveline System - General Information

Driveline Angles @ Curb Specifications

All driveshaft and pinion angles point downward.

General Specifications

a: Service refill capacities are determined by filling the axle 6.3 mm (0.25

in [1/4 in]) to 14.3 mm (0.57 in

[5/16 in]) below the bottom of the ...