Ford Mustang (1999-2004) Service Manual: Disassembly

1. Remove the driveshaft (4602). For additional information, refer to Driveshaft in this section.

2. CAUTION: Under no circumstances is the driveshaft assembly to be clamped in the jaws of a vise or similar holding fixture. Denting or localizing fracture can result, causing driveshaft failure during vehicle operation.

Place the driveshaft on a suitable workbench, being careful not to damage the tube.

3. NOTE: If components are not marked and installed correctly, driveline imbalance can occur.

Index-mark the positions of the driveshaft components.

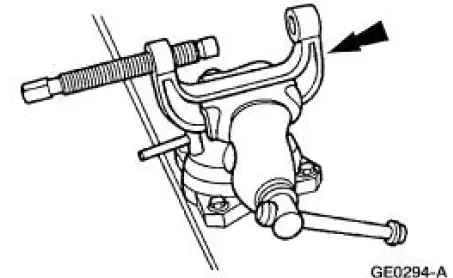

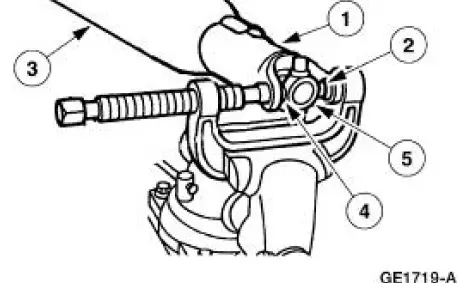

4. Clamp the U-joint tool in a vise.

5. Remove all four of the snap rings.

6. Remove the driveshaft flange yoke.

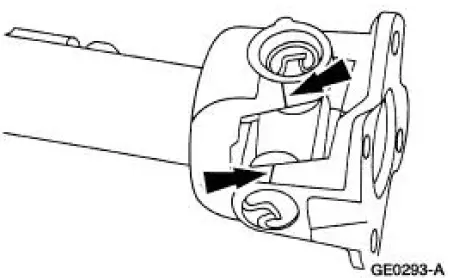

1. Position the driveshaft flange yoke in the U-joint tool.

2. Press out a bearing cup.

3. Remove the driveshaft flange yoke.

4. Press on the spider to remove the remaining bearing cup.

5. Remove the driveshaft flange yoke.

7. Remove the spider.

1. Reposition the driveshaft in the U-joint tool.

2. Press out the bearing cup.

3. Rotate the driveshaft.

4. Press on the spider to remove the remaining bearing cup.

5. Remove the spider.

8. Clean the yoke area at the end of the driveshaft.

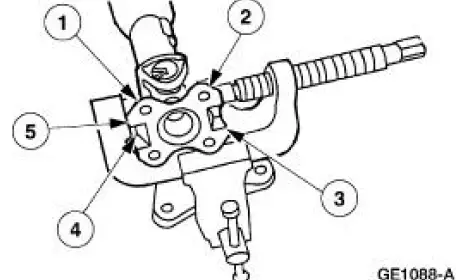

Universal Joint - Single Cardan, Flange Yoke

Universal Joint - Single Cardan, Flange Yoke

Special Tool(s)

Installer/Remover, C Frame

and Screw

205-086 (T74P-4635-C)

...

Assembly

Assembly

1. NOTE: Universal joint kits are to be installed as complete

assemblies only. Do not mix

components from other U-joint kits.

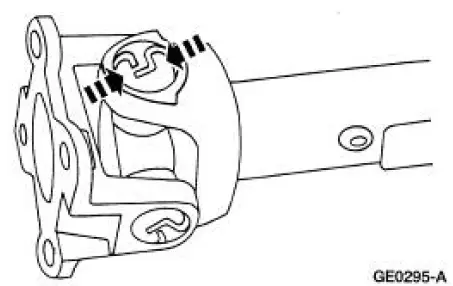

Install the spider.

1. Start a new bearing cup into the driveshaft yok ...

Other materials:

Door Speaker - Upper

Removal and Installation

1. Remove the front door trim panels (239420). For additional

information, refer to Section

2. Remove the upper speaker access cover.

3. Remove the upper speaker housing.

1. Remove the screw.

2. Remove the upper spea ...

Supplementary Restraints System

PRINCIPLES OF OPERATION

WARNING: Airbags do not inflate slowly or gently, and the risk

of injury from a deploying airbag is the greatest close to the trim

covering the airbag module.

WARNING: All occupants of your vehicle, including the driver,

should always p ...

Anti-Lock Control - Traction Control (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 42, Anti-Lock Brake System for schematic and

connector information.

Special Tool(s)

Worldwide Diagnostic System

(WDS)

418-F224,

New Generation STAR (NGS)

Tester

418-F052, or equivalent scan

tool

73 Di ...