Ford Mustang (1999-2004) Service Manual: Valve Springs

Special Tool(s)

|

|

Compressor, Valve Spring 303-163 (T81P-6513-A) |

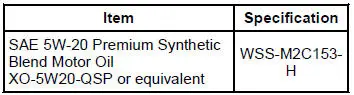

Material

Removal

1. Remove the LH and the RH valve covers. For additional information, refer to Valve Cover-LH and Valve Cover RH in this section.

2. Rotate the crankshaft until the piston for the valve being worked on is at the top of its stroke with both the intake valve and the exhaust valve closed.

3. Hold the valve in the cylinder head.

- Remove the spark plug. For additional information, refer to Section.

- Apply a minimum of 965 kPa (140 psi) of compressed air into the cylinder.

4. CAUTION: If the components are to be reinstalled, they must be installed in the same position. Mark the components for location.

NOTE: If a valve drops into the cylinder, remove the cylinder head. For additional information, refer to Cylinder Head LH or Cylinder Head RH in this section.

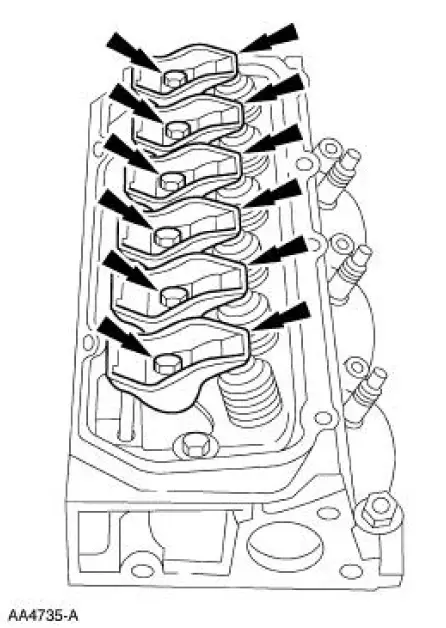

Remove the rocker arms.

1. Remove the bolts.

2. Remove the rocker arms.

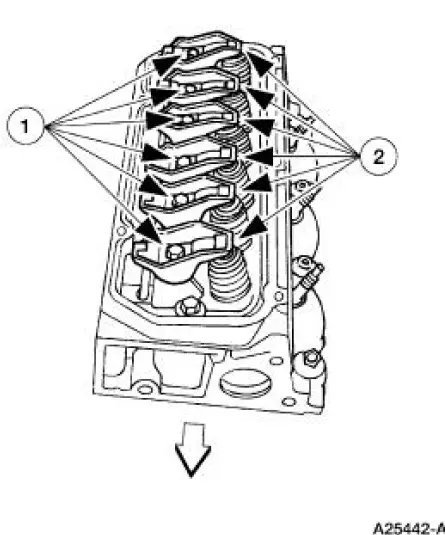

5. Using the special tool, compress the valve springs.

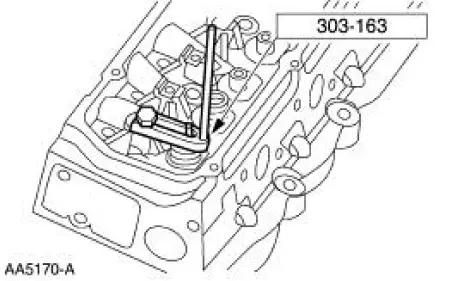

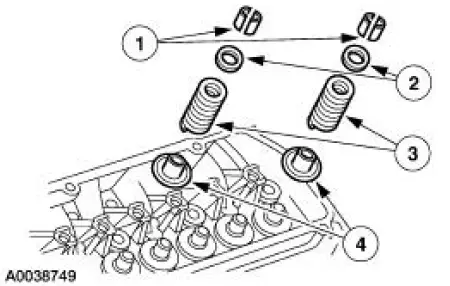

6. Remove the valve spring assembly.

1. Remove the valve spring retainer key.

2. Remove the valve spring retainer.

3. Remove the valve spring.

4. Remove and discard the valve stem seal and spring seat assembly.

7. Inspect the components. For additional information, refer to Section.

Installation

1. NOTE: Lubricate the parts with clean engine oil.

To install, reverse the removal procedure. Tighten the rocker arm bolts in two stages.

- Stage 1: Tighten to 5 Nm (44 lb-in).

- Stage 2: Tighten to 35 Nm (26 lb-ft).

Push Rod

Push Rod

Removal

CAUTION: Mark the components removed for correct location.

1. Remove the rocker arms (6564). For additional information, refer to

Rocker Arm in this section.

2. Remove the push rods (656 ...

Valve Tappets

Valve Tappets

Material

Removal

CAUTION: If removing more than one valve tappet, mark the

components removed for

correct location.

1. Remove the lower intake manifold. For additional information, refer to

Lo ...

Other materials:

Communication Circuit Wiring Repair

Special Tool(s)

Heat Gun

107-R0300 or equivalent

1. Disconnect the battery ground cable. For additional information, refer to

Section.

2. Strip the wires.

3. NOTE: Use rosin core mildly activated (RMA) solder, not acid core

solder.

Solder ...

Fuel Vapor Control Tube Assembly Valve

Removal and Installation

1. Remove the fuel tank. For additional information, refer to

Section.

2. Remove the retainers.

3. NOTE: The fuel vapor vent valve, fuel vapor control valve and the

in-line fuel tank pressure

sensor are repaired as a fuel va ...

Driveshaft (Description and Operation)

NOTE: All driveshaft assemblies are balanced. If undercoating the

vehicle, protect the driveshaft to

prevent overspray of any undercoating material.

The driveshaft has the following features:

A tubular shaft used to transfer engine torque from the ...