Ford Mustang (1999-2004) Service Manual: Engine - 3.8L

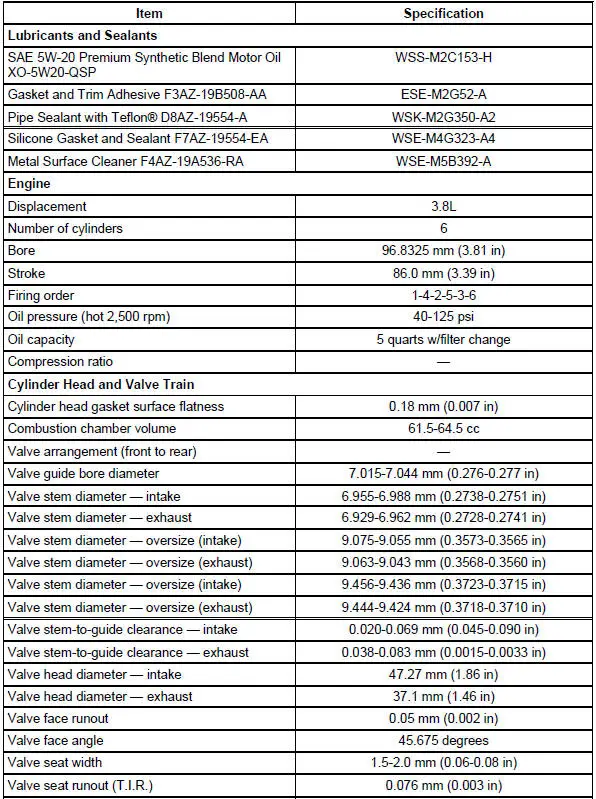

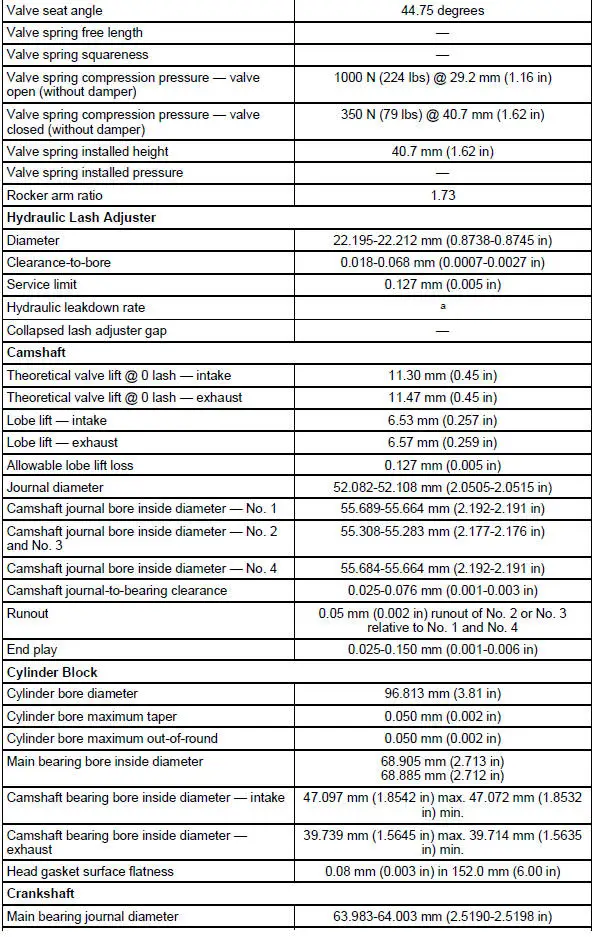

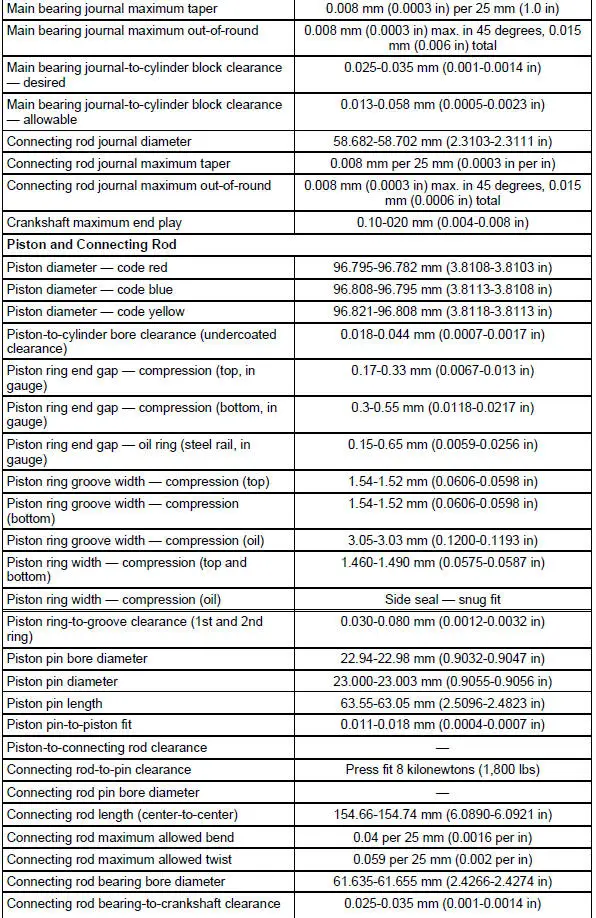

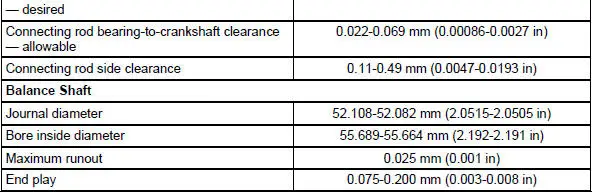

General Specifications

a - 20-200 seconds to leakdown 3.18 mm (0.125 in) with 225 Newtons (50 pounds) load and tappet filled with leak-down fluid.

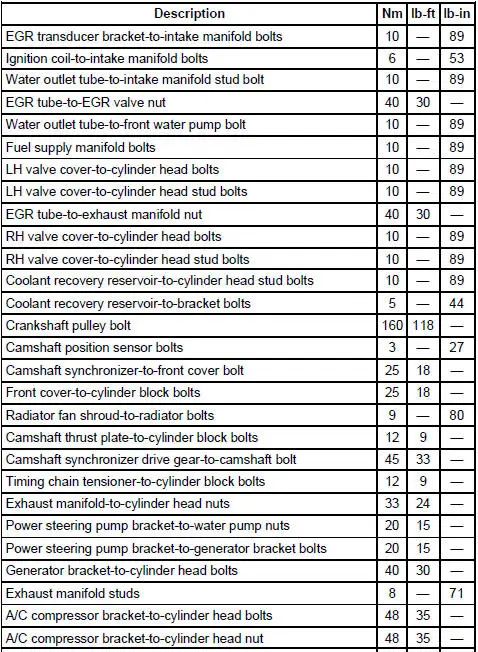

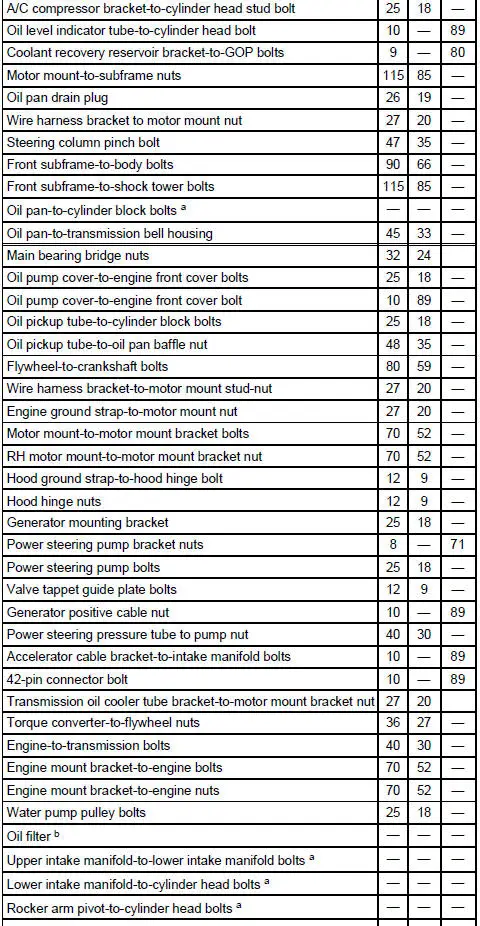

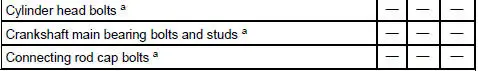

Torque Specifications

a - Refer to the procedure in this section

b - Advance one-half turn after gasket contacts the sealing surface.

Engine (DESCRIPTION AND OPERATION)

The 3.8L engine has:

- a V-block with six cylinders and splayed crankpins.

- a distributorless ignition system.

- a multiport, sequential fuel injection (SFI) system.

- overhead valves.

- hydraulic valve tappets for automatic lash adjustment.

- connecting rod parting faces that are unique with an interference fit.

- an engine dynamic balance shaft.

- Engine Component View

- Upper Intake Manifold

- Lower Intake Manifold

- Valve Cover - LH

- Valve Cover RH

- Crankshaft Pulley

- Crankshaft Front Seal

- Engine Front Cover

- Rocker Arm

- Push Rod

- Valve Springs

- Valve Tappets

- Camshaft

- Engine Dynamic Balance Shaft

- Timing Chain

- Exhaust Manifold - LH

- Exhaust Manifold RH

- Cylinder Head LH

- Cylinder Head RH

- Oil Level Indicator and Tube

- Oil Pan

- Oil Pan Baffle

- Oil Pump Screen and Pickup Tube

- Flexplate

- Crankshaft Rear Seal

- Engine Support Insulators

- Engine (Removal)

- Engine (Disassembly)

- Cylinder Head

- Piston

- Engine (Assembly)

- Engine (Installation)

Exhaust Manifold - Inspection

Exhaust Manifold - Inspection

Special Tool(s)

Straight Edge

303-D039 (D83L-4201-A) or

equivalent

1. Place a straight edge across the exhaust manifold flanges and check for

warping with a feeler

gauge.

Bearing ...

Engine Component View

Engine Component View

Cylinder Heads and Valve Train Components

Engine Front Cover Components

Engine Components

Cylinder Block and Lower End Components

Engine (DIAGNOSIS AND TESTI ...

Other materials:

Air Bag Disposal - Undeployed Inoperative

WARNING: Always wear safety glasses when repairing an air bag

supplemental restraint

system (SRS) vehicle and when handling an air bag module. This will

reduce the risk of injury

in the event of an accidental deployment.

WARNING: Never probe the c ...

Daytime running lamps

WARNING: Always remember to turn on your headlamps at

dusk or during inclement weather. The Daytime Running Lamp

(DRL) system does not activate the tail lamps and generally may not

provide adequate lighting during these conditions. Failure to activate

your hea ...

Diagnostic Strategy

Troubleshooting an electronically controlled automatic transmission

is simplified by using the proven

method of diagnosis. One of the most important things to remember is

that there is a definite

procedure to follow.

NOTE: Do not take any short cut ...