Ford Mustang (1999-2004) Service Manual: Compressor to Condenser Discharge Line - 4.6L

Material

| Item | Specification |

| PAG Refrigerant Compressor Oil (R-134a Systems) F7AZ-19589-DA (Motorcraft YN- 12-C) | WSH-M1C231- B |

Removal and Installation

NOTE: Installation of a new suction accumulator is not required when repairing the air conditioning system except when there is physical evidence of contamination from a failed A/C compressor or damage to the suction accumulator.

1. Recover the refrigerant. For additional information, refer to Section.

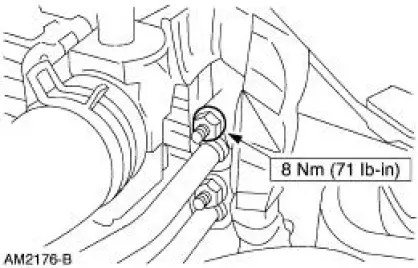

2. Disconnect the dual-function pressure switch electrical connector and remove the switch.

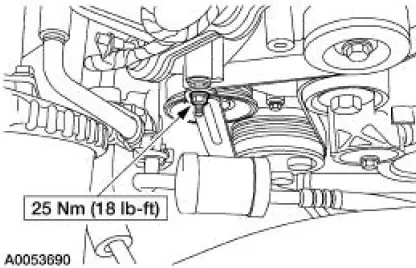

3. Remove the A/C muffler bracket nut.

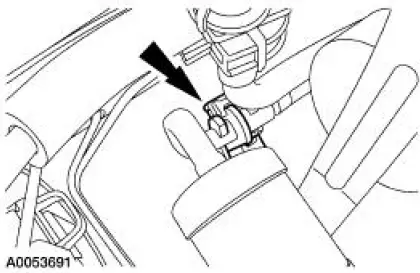

4. Disconnect the fitting at the condenser.

- Discard the O-ring seal.

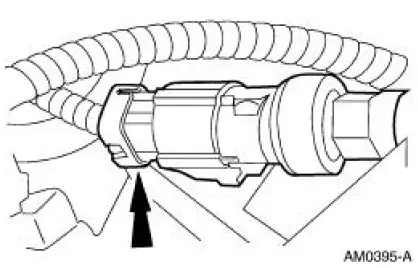

5. Disconnect the spring lock coupling at the compressor manifold and tube.

- Discard the O-ring seals.

6. Remove the compressor to condenser discharge line.

7. To install, reverse the removal procedure.

- Install new O-ring seals lubricated in clean PAG oil. For additional information, refer to Section.

- Lubricate the refrigerant system with the correct amount of clean PAG oil. For additional information, refer to Section.

8. Evacuate, leak test and charge the refrigerant system. For additional information, refer to Section.

Suction Accumulator to Compressor Line - 4.6L

Suction Accumulator to Compressor Line - 4.6L

Material

Item

Specification

PAG Refrigerant Compressor

Oil (R-134a Systems)

F7AZ-19589-DA (Motorcraft YN-

12-C)

WSH-M1C231-

B

Removal and Installation

NOTE: Installation of a ...

Condenser to Evaporator Line

Condenser to Evaporator Line

Material

Item

Specification

PAG Refrigerant Compressor

Oil (R-134a Systems)

F7AZ-19589-DA (Motorcraft YN-

12-C)

WSH-M1C231-

B

Removal and Installation

NOTE: Installation of a ...

Other materials:

Pinpoint Test F: LFC 16/DTC B1888 - Passenger Air Bag Circuit Shorted to

Ground

Normal Operation

The restraints control module (RCM) checks for passenger air bag circuit

shorts to ground by

monitoring the voltage of circuits 607 (LB/OG) and 616 (PK/BK) at pins 6 and

7. If the RCM detects a

short to ground on either of these pins, i ...

Exterior Trim and Ornamentation

Torque Specifications

Exterior Trim and Ornamentation

The exterior trim and ornamentation consists of the following

components:

body side scoop

hood scoop (if equipped)

front spoiler (Mach 1)

radiator grille

rear spoiler (if equipped)

...

Summer tires (if equipped)

Summer tires provide superior performance on wet and dry roads. Summer

tires do not have the Mud and Snow (M+S or M/S) tire traction rating on the

tire side wall. Since summer tires do not have the same traction performance

as All-season or Snow tires, Ford do ...