Ford Mustang (1999-2004) Service Manual: Connecting Rod - Side Clearance

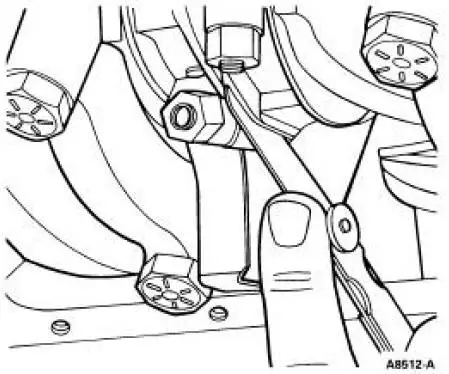

1. Measure the clearance between the connecting rod and the crankshaft. Verify the measurement is within specification.

- Refer to the appropriate section in Group for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group for the procedure.

Roller Follower -Inspection

Push rod engines

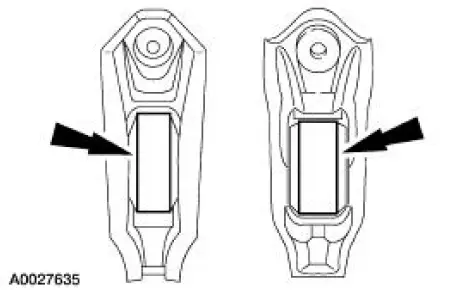

1. Inspect the roller for flat spots or scoring. If any damage is found, inspect the camshaft lobes and valve tappet for damage.

OHC engines

Valve Tappet -Inspection

Push rod engines

1. Inspect the hydraulic valve tappet and roller for damage. If any damage is found, inspect the camshaft lobes and valves for damage.

OHC engines

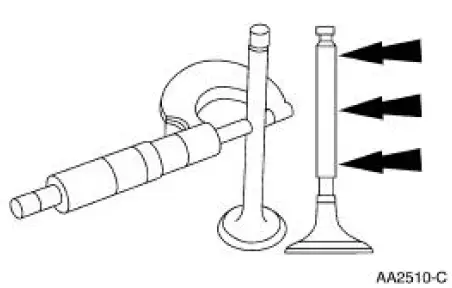

Valve -Stem Diameter

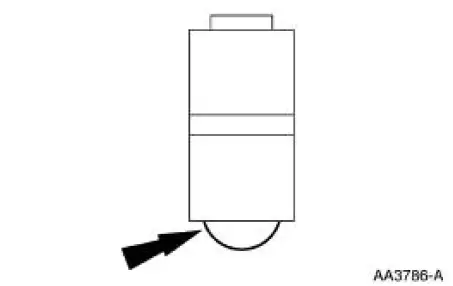

1. Measure the diameter of each intake and exhaust valve stem at the points shown. Verify the diameter is within specification.

- Refer to the appropriate section in Group for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group for the procedure.

Connecting Rod - Bearing Journal Clearance

Connecting Rod - Bearing Journal Clearance

Special Tool(s)

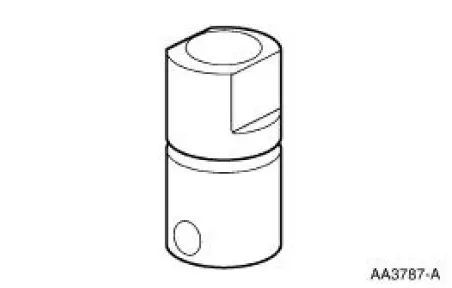

Plastigage

303-D031 (D81L-6002-B) or

equivalent

NOTE: The crankshaft connecting rod journals must be within

specifications to check the connecting

rod bearing journa ...

Valve Stem to Valve Guide Clearance

Valve Stem to Valve Guide Clearance

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Clearance Gauge, Valve Guide

303-004 (TOOL-6505-E) or

equivalent

NOTE: Valve ...

Other materials:

Water Pump

Removal and Installation

1. Disconnect the battery ground cable.

2. Drain the coolant. For additional information, refer to Supercharger Cooling

System Draining,

Filling and Bleeding in this section.

3. Remove the retainer and position the inner fender well ...

Transmission Fluid Cooler - Backflushing and Cleaning

1. CAUTION: Do not use any supplemental transmission fluid

additives or cleaning

agents. The use of these products could cause internal transmission

components to fail;

this will effect the operation of the transmission.

Conduct backflushing with a sui ...

Inspection and Verification

WARNING: Use of any other than the approved DOT 3 brake fluid will

cause permanent

damage to brake components and will render the brakes inoperative.

WARNING: Brake fluid contains polyglycol ethers and polyglycols. Avoid contact

with

eyes. Wash hands thorou ...