Ford Mustang (1999-2004) Service Manual: Engine System - General Information

General Specifications

Engine

NOTE: This section contains information, steps and procedures that may not be specific to your engine.

This section covers general procedures and diagnosis and testing of the engine system, except for exhaust emission control devices, which are covered in the Powertrain Control/Emissions Diagnosis Manual.

The engine incorporates the following features:

- a closed positive crankcase ventilation (PCV) system.

- an exhaust emission control system.

- an evaporative emission control system.

Some engines incorporate a fail-safe cooling system. Refer to the appropriate section in Group for the procedure.

The engine, fuel system, ignition system, emissions system and exhaust system all affect exhaust emission levels and must be maintained according to the maintenance schedule. Refer to the scheduled Maintenance Guide.

Correct engine identification is required to order parts. Refer to the appropriate section in Group for the procedure.

For complete vehicle and engine identification codes.

- Engine (Diagnosis and Testing)

- Sprockets

- Rocker Arms - Inspection

- Push Rods - Inspection

- Camshaft Journal - Clearance, Plastigage Method

- Camshaft End Play - Push Rod Engines

- Camshaft End Play - OHC Engines

- Camshaft Lobe Lift

- Camshaft Runout

- Crankshaft Main Bearing Journal - Clearance

- Crankshaft End Play

- Crankshaft Runout

- Crankshaft - Connecting Rod Journal Taper, Out of Round

- Piston Inspection

- Piston - Pin to Bore Diameter

- Piston - Selection

- Piston - Ring End Gap

- Piston - Ring-to-Groove Clearance

- Piston - Pin Diameter

- Connecting Rod - Bushing Diameter

- Connecting Rod - Twist

- Connecting Rod - Bearing Journal Clearance

- Connecting Rod - Side Clearance

- Valve Stem to Valve Guide Clearance

- Valve Spring Strength

- Valve - Seat Inspection

- Cylinder Head - Distortion

- Cylinder Block Core Plug Replacement

- Spark Plug - Inspection

- Exhaust Manifold - Inspection

Engine

Engine

...

Engine (Diagnosis and Testing)

Engine (Diagnosis and Testing)

Special Tool(s)

Commercially Available

Leakdown Tester

Quick Disconnect Compression

Tester

134-R0212 or equivalent

Dial Indicator Gauge Adapter

303-007 (TOOL-6565-AB) ...

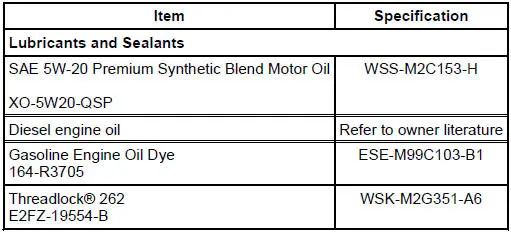

Other materials:

Disassembly

1. Remove the differential assembly from the differential housing. For

additional information, refer

to Differential Case in this section.

2. Remove the bolts.

3. CAUTION: Do not damage the threads in the bolt holes.

Insert a punch in the bolt holes and d ...

Fill

1. WARNING: Do not mix oil types, any mixture or any unapproved oil can

lead to seal

deterioration and leaks. A leak can ultimately cause loss of fluid, which can

result in a

loss of power steering assist.

Check the fluid level. If necessary, fill the reserv ...

Assembly

1. Lubricate the differential side gear thrust washers and the differential

side gear journals, and

assemble the washers to the gears.

Use SAE 75W-140 High Performance Rear Axle Lubricant F1TZ-19580-B or

equivalent

meeting Ford specification WSL-M2C192-A ...