Ford Mustang (1999-2004) Service Manual: Crankshaft Runout

Special Tool(s)

|

|

Dial Indicator Gauge with Holding Fixture 100-002 (TOOL-4201-C) or equivalent |

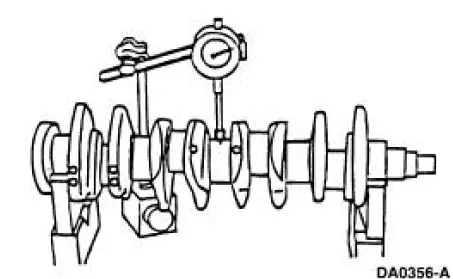

1. NOTE: Crankshaft main bearing journals must be within specifications before checking runout.

Use the Dial Indicator Gauge with Holding Fixture to measure the crankshaft runout.

- Refer to the appropriate section in Group 303 for the procedure.

- Rotate the crankshaft and subtract the lowest dial indicator reading from the highest dial indicator reading to figure the crankshaft runout. If it is out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Crankshaft End Play

Crankshaft End Play

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

1. Measure the crankshaft end play. Use a Dial Indicator Gauge with Holding

Fixture t ...

Crankshaft - Connecting Rod Journal Taper, Out of Round

Crankshaft - Connecting Rod Journal Taper, Out of Round

1. Measure the crankshaft connecting rod journal diameters in two

directions perpendicular to one

another at each end of the connecting rod journal. The difference in the

measurements from

one e ...

Other materials:

Getting the services you need

Warranty repairs to your vehicle must be performed by an authorized

dealer. While any authorized dealer handling your vehicle line will

provide warranty service, we recommend you return to your selling

authorized dealer who wants to ensure your continued satis ...

Spark Plugs

Removal and Installation

1. Remove the ignition coil-on-plug. For additional information, refer to

Ignition Coil-On-Plug in this

section.

2. NOTE: Use compressed air to remove any foreign material from the

spark plug well before

removing the spark plu ...

Inspection and Verification

WARNING: Never remove the pressure relief cap while the engine is

operating or when the

cooling system is hot. Failure to follow these instructions can result in damage

to the cooling

system or engine or personal injury. To avoid having scalding hot coolant ...