Ford Mustang (1999-2004) Service Manual: Disassembly

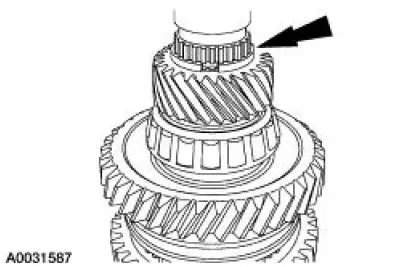

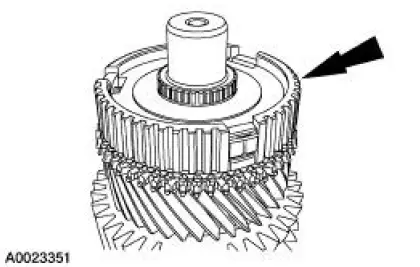

1. Remove the retaining ring above fifth gear.

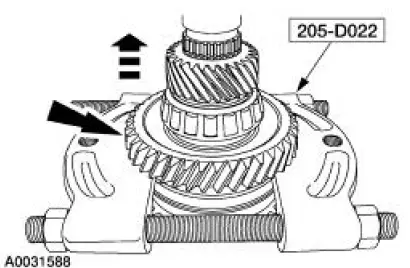

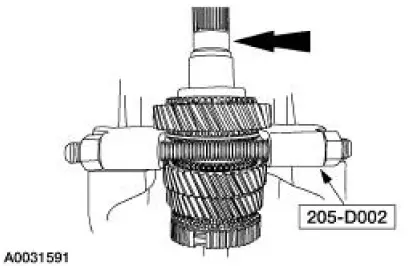

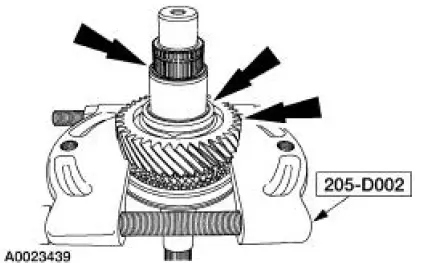

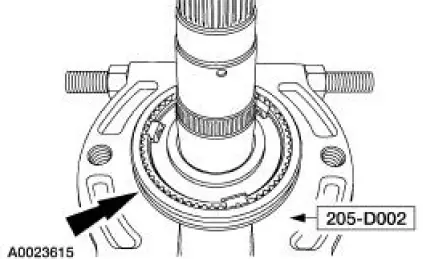

2. CAUTION: Hand tighten the special tool to prevent gear damage.

CAUTION: Support the output shaft while using the press to prevent damage to the shaft or gears.

Using the special tool, press fifth gear, the spacer, the output shaft bearing and reverse gear from the output shaft.

- Discard the output shaft bearing.

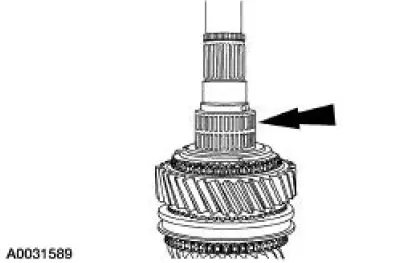

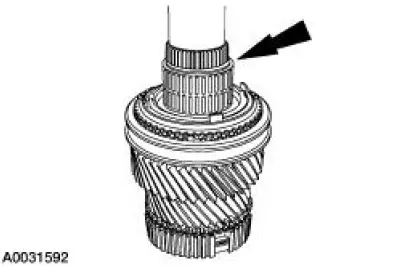

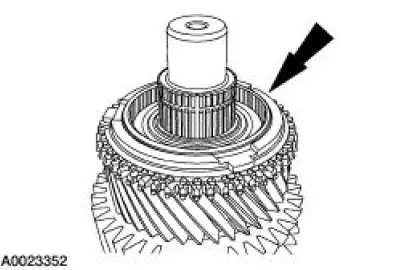

3. Remove reverse gear needle bearing.

- Inspect the needle bearing for wear or damage. Install a new needle bearing as necessary.

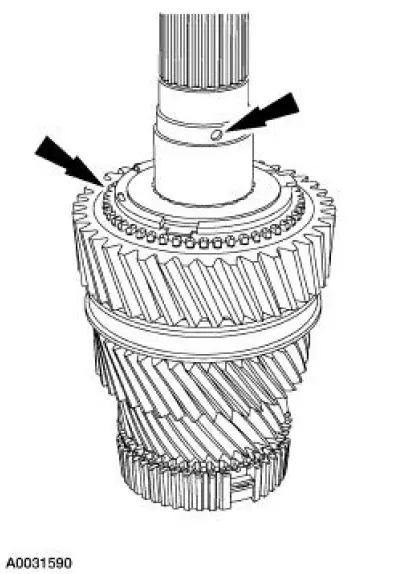

4. Remove the check ball and the blocking ring.

- Inspect the blocking ring for wear or damage. Install new blocking rings as necessary.

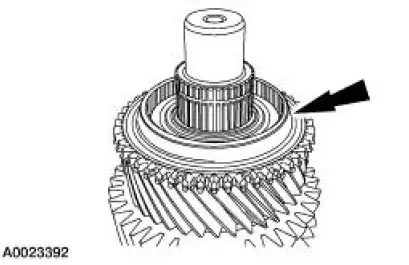

5. NOTE: Install the special tool with the flat side facing first gear.

Using the special tools, press the bearing spacer, the reverse gear synchronizer cone and first gear from the output shaft.

6. Remove the first gear needle bearing.

- Inspect the needle bearing for wear or damage. Install a new needle bearing as necessary.

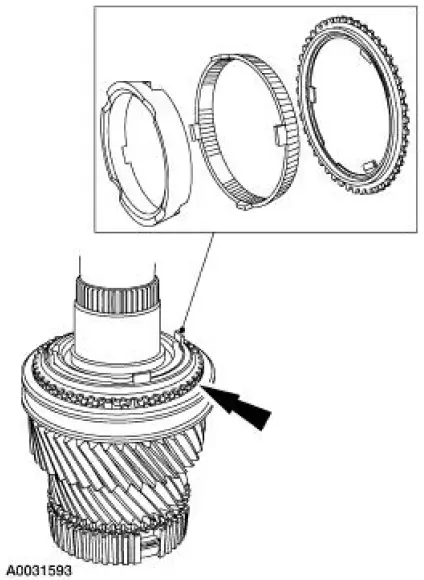

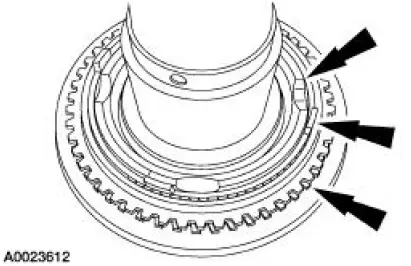

7. Remove the first gear synchronizer inner cone, the first gear synchronizer outer cone and the first gear synchronizer blocking ring.

- Inspect all components for wear or damage. Install new components as necessary.

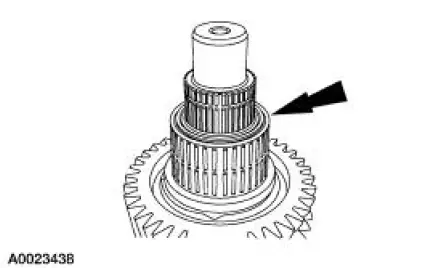

8. NOTE: Reposition the output shaft on the press with the input shaft end facing upward.

- Remove and discard the retaining ring.

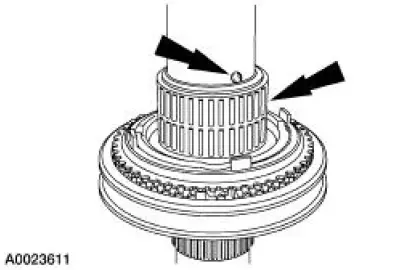

9. Remove the third/fourth synchronizer hub.

10. Remove the third/fourth blocking ring.

11. Remove the third gear.

- Inspect the gear for wear or damage. Install a new gear as necessary.

12. Remove the third gear needle bearing.

- Inspect the needle bearing for wear or damage. Install a new needle bearing as necessary.

13. NOTE: Install the special tool behind second gear with the flat side of the tool facing second gear.

Using the special tool, remove the spacer, second gear thrust washer and second gear.

- Inspect the gear for wear or damage. Install a new gear as necessary.

14. Remove the check ball and second gear needle bearing.

- Inspect the needle bearing for wear or damage. Install a new needle bearing as necessary.

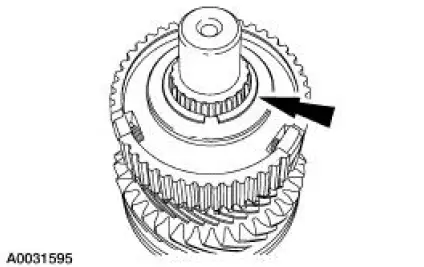

15. Remove the second gear synchronizer inner cone, second gear synchronizer outer cone and the second gear synchronizer blocking ring.

- Inspect all components for wear or damage. Install new components as necessary.

16. Remove the snap ring, then using the special tool, press off the first/second gear synchronizer.

Output Shaft

Output Shaft

Special Tool(s)

Remover, Drive Pinion Bearing

Cone

205-D002 (D79L-4621-A) or

equivalent

Installer, Drive Pinion Bearing

Cone

205-011 (T57L-4621-B)

...

Assembly

Assembly

1. Carry out the following before reassembling:

Inspect the gears for broken or cracked teeth. Check for unusual wear

patterns.

Inspect the thrust washers for face wear, cracks, scoring and for s ...

Other materials:

Steering Column Switches

Torque Specifications

Steering Column Switches (DESCRIPTION AND OPERATION)

The steering column switches system consists of the following components:

multifunction switch (13K359)

key release button (manual transmission only) (3F527)

ignition switch (11572 ...

Battery Cables

Removal

WARNING: Batteries normally produce explosive gases which can

cause personal injury.

Therefore, do not allow flames, sparks or lighted substances to come

near the battery. When

charging or working near a battery, always shield your face an ...

Transmission (REMOVAL)

Special Tool(s)

Retainer, Torque Converter

307-346 (T97T-7902-A)

CAUTION: Whenever a transmission has been disassembled to install new

parts the

transmission fluid cooler tubes must be cleaned and backflushed. Use a suitable

torque

converter/ ...