Ford Mustang (1999-2004) Service Manual: Disassembly

1. Remove the driveshaft (4602). For additional information, refer to Driveshaft in this section.

2. CAUTION: Under no circumstances is the driveshaft assembly to be clamped in the jaws of a vise or similar holding fixture. Denting or localizing fracture can result, causing driveshaft failure during vehicle operation.

Place the driveshaft (4602) on a suitable workbench. Be careful not to damage the tube.

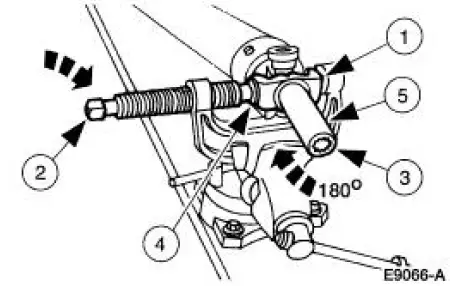

3. NOTE: If components are not marked and therefore installed incorrectly, driveline imbalance can occur.

Index-mark the driveshaft components.

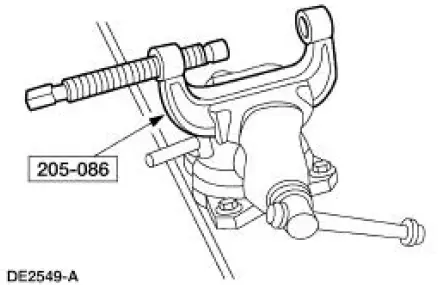

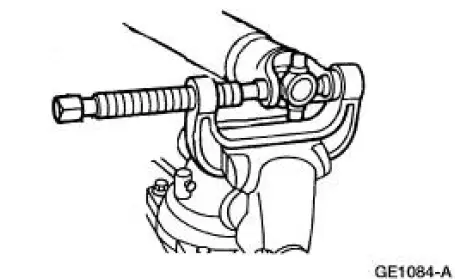

4. Clamp the special tool in a vise.

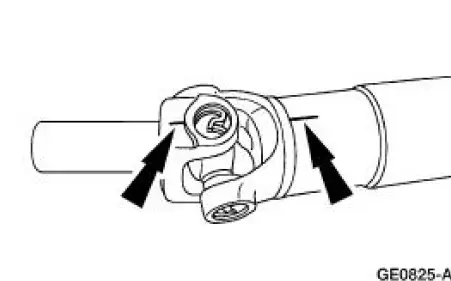

5. Remove all four of the snap rings.

6. NOTE: If necessary, use a pair of pliers to remove a bearing cup if it cannot be pressed out all the way.

Remove the driveshaft slip yoke (4841).

1. Position the driveshaft slip yoke in the U-joint tool.

2. Press out a bearing cup.

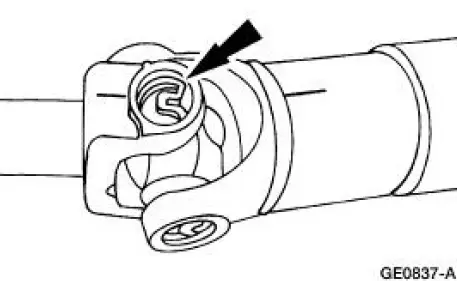

3. Rotate the driveshaft slip yoke.

4. Press on the spider to remove the remaining bearing cup.

5. Remove the driveshaft slip yoke.

7. Repeat Step 5 to remove the remaining bearing cups and spider from the driveshaft.

8. Clean the yoke area at each end of the driveshaft.

Driveshaft Slip Yoke

Driveshaft Slip Yoke

Special Tool(s)

Installer/Remover, C Frame

and Screw

205-086 (T74P-4635-C)

...

Assembly

Assembly

1. NOTE: Universal joint service kits are to be installed as complete

assemblies only. Do not mix

components from other U-joint kits.

Install the bearing cup.

1. Start a new bearing cup into the d ...

Other materials:

Diagnosis By Symptom

Special Tool(s)

Transmission Fluid Pressure

Gauge

307-004 (T57L-77820-A)

Air Test Plate, Transmission

307-246 (T92P-7006-A)

Breakout Box, EEC-V Control

System

418-049 (T94L-50-EEC-V) or

equivalent

MLP- ...

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number must be installed if installation becomes necessary. ...

Heated seats

WARNING: Persons who are unable to feel pain to the skin

because of advanced age, chronic illness, diabetes, spinal cord

injury, medication, alcohol use, exhaustion, or other physical conditions,

must exercise care when using the seat heater. The seat heater m ...