Ford Mustang (1999-2004) Service Manual: Driveline Angle Inspection

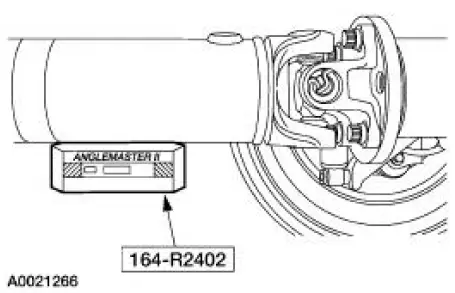

Special Tool(s)

|

|

Anglemaster II Driveline Inclinometer 164-R2402 or equivalent |

NOTE: An incorrect driveline angle can cause a vibration or shudder.

1. Check the vehicle for evidence or overload or sagging. Check for specified air pressures information in all four tires.

2. Normalize the suspension.

3. Drive the vehicle onto a drive-on hoist or back onto a front-end alignment rack.

4. Inspect the suspension and chassis. Verify that the vehicle curb position ride height is within specification.

- Measure the curb position ride height with the vehicle empty and all fluids full.

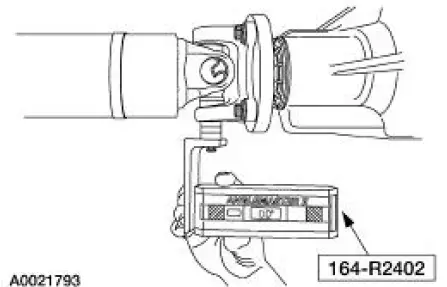

5. Place the Inclinometer flush against the bottom of the driveshaft. After the tool has been held on the driveshaft surface for 5 seconds, push the ALT ZERO button to calibrate to zero degrees.

Remove the tool.

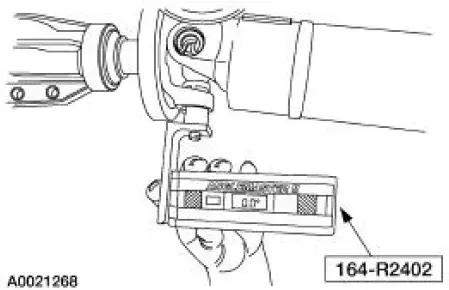

6. To check the pinion angle, rotate the driveshaft so that the rear axle pinion flange yoke ear is parallel to the floor. Remove the U-joint snap ring, then install the special tool. Check and record the pinion angle reading.

- If the angle is not within specification, repair or adjust to obtain the correct angle. Inspect the rear suspension, rear axle, rear axle mounting or the frame for wear or damage.

7. To check the engine angle, rotate the driveshaft so that the slip yoke ear is parallel to the floor.

Remove the U-joint snap ring, then install the special tool. Check and record the engine angle reading.

- If the angle is not within specifications, repair or adjust to obtain

the correct angles.

Inspect the powertrain/drivetrain mounts or frame rails for wear or damage.

Component Tests

Component Tests

Driveline Vibration

An analysis of driveline vibration can also be conducted using the Vibration

Analyzer; follow the

manufacturer's directions.

Driveline vibration exhibits a higher frequency and l ...

Axle Housing Casting Porosity (Holes in Casting) Repair

Axle Housing Casting Porosity (Holes in Casting) Repair

CAUTION: To keep the axle's sound characteristics, do not disassemble

the carrier.

NOTE: Casting porosity is a condition where occasionally gas bubbles will

form during the casting

process leaving s ...

Other materials:

Brake Booster - Hydro-Boost (Description and Operation)

The Hydro-Boost brake booster is a hydraulically operated brake booster

powered by the power

steering pump (3A674). The power steering pump provides the fluid pressure to

operate both the

power brake booster and the power steering gear (3504).

A Hydro-Boost ...

Air Conditioning (A/C) Pressure Relief Valve - 4.6L

Material

Item

Specification

PAG Refrigerant Compressor

Oil (R-134a Systems)

F7AZ-19589-DA (Motorcraft YN-

12-C)

WSH-M1C231-

B

Removal and Installation

NOTE: Installation of a new suction accumulator is not required when

repairing the ...

Axle Housing Casting Porosity (Holes in Casting) Repair

CAUTION: To keep the axle's sound characteristics, do not disassemble

the carrier.

NOTE: Casting porosity is a condition where occasionally gas bubbles will

form during the casting

process leaving small pockets in the metal that will cause the axle housing t ...