Ford Mustang (1999-2004) Service Manual: Driveshaft (Removal and Installation)

Material

| Item | Specification |

| Threadlock and Sealer E0AZ-19554-AA | WSK-M2G351-A5 (type II) |

Removal and Installation

1. Raise and support the vehicle.

2. Carry out the following:

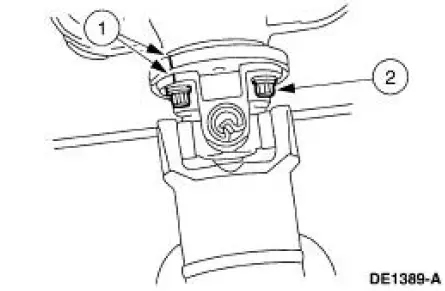

1. Place an index mark on the rear axle pinion flange and the driveshaft centering socket yoke.

2. Remove the four bolts.

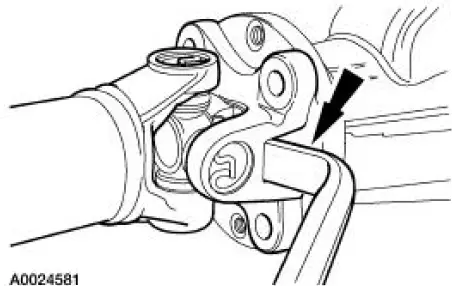

3. CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. Never hammer on the driveshaft or any of its components to disconnect the yoke from the flange. Pry only in the area shown, with a suitable tool, to disconnect the yoke from the flange.

Using a suitable tool as shown, disconnect the driveshaft centering socket yoke from the rear axle pinion flange.

4. CAUTION: Do not allow the slip yoke to bottom on the transmission output shaft.

Lower the rear end of the driveshaft to clear the rear axle housing. Pull the driveshaft rearward until the driveshaft slip yoke clears the transmission extension housing.

- Place a paint index mark on the driveshaft slip yoke and the transmission output shaft.

- Place a commercially available plug in the extension housing to prevent fluid leakage.

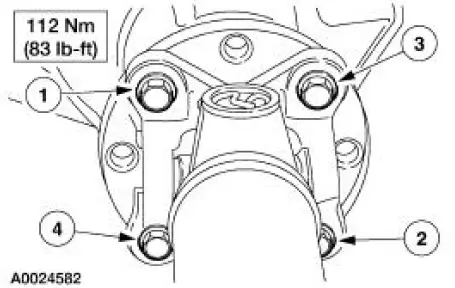

5. CAUTION: Install the driveshaft with new bolts. If new bolts are not available, apply threadlock and sealer to the threads of the original bolts.

CAUTION: Do not allow the slip yoke to bottom on the transmission output shaft.

CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. To make sure that the yoke seats squarely on the flange, tighten the bolts evenly in a cross pattern as shown.

NOTE: Clean all foreign material from the yoke areas of the driveshaft.

To install, reverse the removal procedure.

Universal Joints

Universal Joints

The universal joints are:

lubed-for-life design and require no lubrication.

equipped with nylon thrust washers, located at each base of the bearing

cup, which control end

play, position the need ...

Driveshaft - Cobra

Driveshaft - Cobra

Material

Item

Specification

Threadlock and Sealer

E0AZ-19554-AA

WSK-M2G351-A5 (type

II)

Silicone Lubricant

(Aerosol)

F5AZ-19553-AA

ESR-M13P4-A

Removal and Installatio ...

Other materials:

Fittings - Vapor Tube

Disconnect

1. WARNING: The evaporative emission system contains fuel vapor and

condensed

fuel vapor. Although not present in large quantities, it still presents the

danger of

explosion or fire. Disconnect the battery ground cable from the battery to

minimiz ...

Manual seats

WARNING: Do not adjust the driver’s seat or seatback while the

vehicle is moving.

WARNING: Rock the seat backwards and forwards after

releasing the lever to make sure that it is fully engaged.

Moving the seats backward and

forward

Recline adjustment

WARNIN ...

Column

Removal and Installation

All vehicles

1. Disconnect the battery ground cable and wait at least one minute to allow

the depletion of the

restraint system backup power supply.

2. WARNING: To avoid the risk of serious personal injury, follow all

warnings,

c ...