Ford Mustang (1999-2004) Service Manual: Driveshaft - Cobra

Material

| Item | Specification |

| Threadlock and Sealer E0AZ-19554-AA | WSK-M2G351-A5 (type II) |

| Silicone Lubricant (Aerosol) F5AZ-19553-AA | ESR-M13P4-A |

Removal and Installation

1. Raise and support the vehicle.

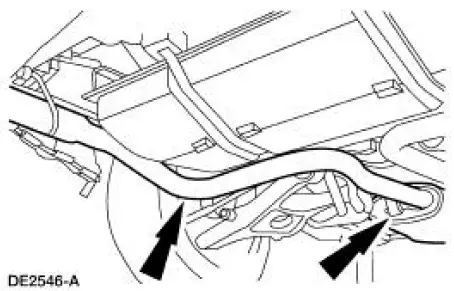

2. NOTE: To aid disassembly and assembly, lubricate the exhaust hangers with silicone lubricant.

Remove the two exhaust hangers from the rubber mounts.

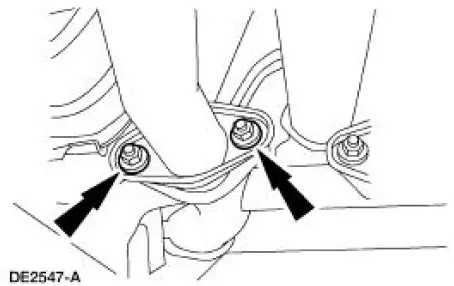

3. Remove the nuts on the left side exhaust.

4. Lower the muffler pipe enough to clear the flange. Move the muffler assembly forward to disconnect the third exhaust hanger.

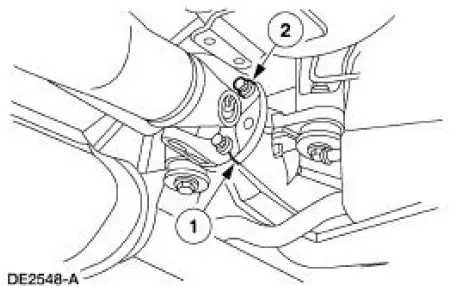

5. Carry out the following:

1. Place an index mark on the rear axle pinion flange and the driveshaft centering socket yoke.

2. Remove the four bolts.

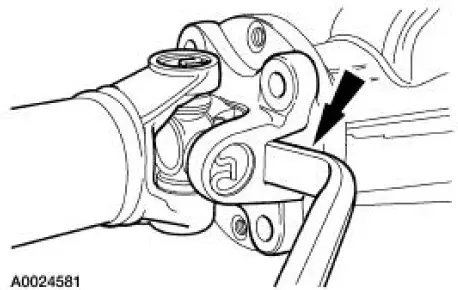

6. CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. Never hammer on the driveshaft or any of its components to disconnect the yoke from the flange. Pry only in the area shown, with a suitable tool, to disconnect the yoke from the flange.

Using a suitable tool as shown, disconnect the driveshaft centering socket yoke from the rear axle pinion flange.

7. CAUTION: Do not allow the slip yoke to bottom on the transmission output shaft.

Lower the rear end of the driveshaft to clear the rear axle housing. Pull the driveshaft rearward until the driveshaft slip yoke clears the transmission extension housing.

- Place a paint index mark on the driveshaft slip yoke and the transmission output shaft.

- Place a commercially available plug in the extension housing to prevent fluid leakage.

8. CAUTION: Install the driveshaft with new bolts. If new bolts are not available, apply threadlock and sealer to the threads of the original bolts.

CAUTION: Do not allow the slip yoke to bottom on the transmission output shaft.

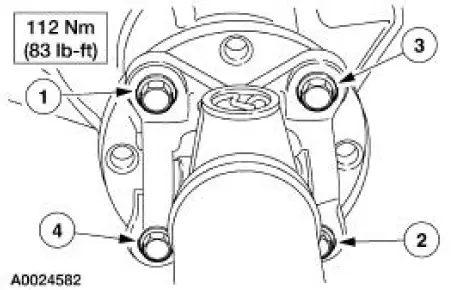

CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. To make sure that the yoke seats squarely on the flange, tighten the bolts evenly in a cross pattern as shown.

NOTE: Clean all foreign material from the yoke areas of the driveshaft.

To install, reverse the removal procedure.

Driveshaft (Removal and Installation)

Driveshaft (Removal and Installation)

Material

Item

Specification

Threadlock and

Sealer

E0AZ-19554-AA

WSK-M2G351-A5 (type

II)

Removal and Installation

1. Raise and support the vehicle.

2. Carry out the following:

...

Driveshaft Slip Yoke

Driveshaft Slip Yoke

Special Tool(s)

Installer/Remover, C Frame

and Screw

205-086 (T74P-4635-C)

...

Other materials:

Starter Motor - 4.6L

Removal

WARNING: When servicing starter motor (11002) or carrying out other

underhood work in

the vicinity of the starter motor, be aware that the heavy gauge battery

input lead at the starter

solenoid (11390) is "electrically hot" at all times. A prote ...

Antenna (Removal and Installation)

Removal

1. Lower the glove compartment by releasing the stops from the

instrument panel.

2. Disconnect the antenna in-line connector

3. Remove the antenna base and cable.

1. Remove the radio antenna base cap.

2. Remove the screws.

3. Re ...

Pinpoint Tests

PINPOINT TEST A: THE CONTROL ILLUMINATION IS INOPERATIVE

Test Step

Result / Action to Take

A1 CHECK PARKING LAMPS

YesPlace the headlamp switch in the OFF

position.

GO to A2 .

No

REFER to Section.

Place the headlamp switch ...