Ford Mustang (1999-2004) Service Manual: Electronic Leak Detection

Special Tool(s)

|

H10PM Refrigerant Leak Detector With Battery 216-00001 or equivalent |

CAUTION: Good ventilation is necessary in the area where electronic A/C leak testing is to be carried out. If the surrounding air is contaminated with refrigerant gas, the leak detector will indicate this gas all the time. Odors from other chemicals such as anti-freeze, diesel fuel, disc brake cleaner, or other cleaning solvents can cause the same problem. A fan, even in a wellventilated area, is very helpful in removing small traces of contamination from the air that might affect the leak detector.

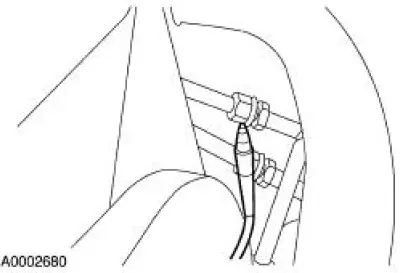

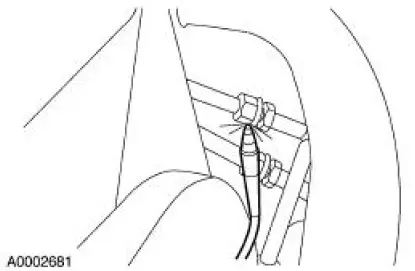

1. NOTE: The system pressure should be between 413-551 kPa (60-80 psi) at 24C (75F) with the engine off.

Leak test the refrigerant system using the Refrigerant Leak Detector. Follow the instructions included with the leak detector for handling and operation techniques.

2. If a leak is found, discharge and recover the refrigerant. For additional information, refer to Air Conditioning (A/C) System Recovery, Evacuation and Charging in this section.

- Repair the system.

- Test the system for normal operation.

Manifold Gauge Set Connection

Manifold Gauge Set Connection

Special Tool(s)

R-134a Manifold Gauge Set

176-R032A or equivalent

1. Turn both valves on the R-134a Manifold Gauge Set clockwise to close the

low- and highpressure

hoses to the center ...

Tracer Dye Leak Detection

Tracer Dye Leak Detection

Special Tool(s)

120 Watt 110 Volt UV Lamp

20C

164-R0721 or equivalent

NOTE: Ford Motor Company vehicles are produced with a permanent leak

tracer dye incorporated into

the A/C syste ...

Other materials:

Disassembly

1. CAUTION: Hand tighten the special tool to prevent gear damage.

CAUTION: Support the output shaft while using the press to prevent

damage to the

shaft or gears.

Using the special tool and a press, remove first gear, the output shaft rear

bearing ...

Crankshaft Front Seal

Special Tool(s)

Installer, Front Cover Oil Seal

303-335 (T88T-6701-A)

Installer, Crankshaft Front Oil

Seal

303-474 (T94P-6701-AH)

Remover, Oil Seal

303-409 (T92C-6700-CH)

Material

Removal

1. Remove the crankshaft pulley. ...

Waxing

Regular waxing is necessary to protect the paint on your car from the

elements. We recommend that you wash and wax the painted surface

once or twice a year.

When washing and waxing, park your vehicle in a shaded area out of

direct sunlight. Always wash your v ...