Ford Mustang (1999-2004) Service Manual: Headlamp Adjustment

Headlamp Aiming

1. The headlamp aiming procedure depends on the type of beam pattern the headlamp is equipped with. Vehicles may come equipped with visual optical right (VOR), visual optical left (VOL), or SAE only (includes sealed beam type) headlamps. To identify the headlamp beam pattern, look on the headlamp lens. Molded in small letters on the headlamp lens is one of the following:

- SAE

- VOR or SAE

- VOL or SAE

2. Once the headlamp beam pattern is identified, aim the headlamps using one of the following methods as applicable.

- Photometric aimers can aim SAE, VOR and VOL type headlamps. This is the preferred method of headlamp aiming.

- Visual or screen method aiming can be used to aim SAE, VOR and VOL type headlamps.

- Mechanical aimers can be used only with SAE type headlamps. Lamps that can be aimed mechanically will have three nibs molded into the lens of the lamp.

Photometric Aiming

1. For the photometric aiming procedure, refer to the appropriate photometric headlamp aimer instruction manual.

Screen Method Aiming

All headlamp types

NOTE: Horizontal aim is not necessary for VOR or VOL headlamps.

NOTE: Consult your state vehicle inspection manual for recommended tolerance ranges for visual aiming.

NOTE: The sight shield may need to be positioned or removed for access to the adjusters.

1. Before starting headlamp adjustment:

- Check the tire inflation.

- Check that no other load is in the vehicle other than a half tank of fuel.

- Check that the headlamps are clean.

- Check for correct headlamp operation.

- Check that the vehicle is on level ground.

- If the vehicle is equipped with air suspension, make sure that the switch is on.

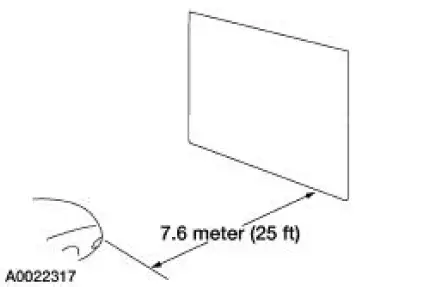

2. NOTE: The vertical wall or screen must be a minimum of 2.4 meters (8 feet) wide.

Park the vehicle on a level surface approximately 7.6 meters (25 feet) from the vertical wall or screen directly in front of it.

3. NOTE: The center of the lamp is marked by a 3 mm (0.12 in) circle on the headlamp lens.

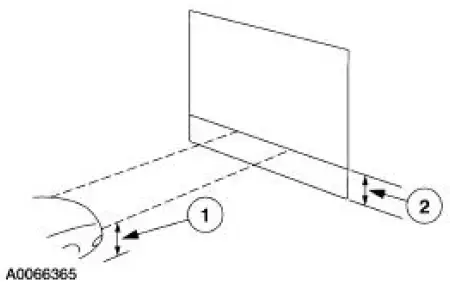

Mark a horizontal reference line on the vertical wall or screen.

1. Measure the center of the headlamp height to ground and record.

2. Make a 2.4 meter (8 foot) horizontal mark (masking tape) on the vertical wall or screen at the same distance from the ground as previously recorded.

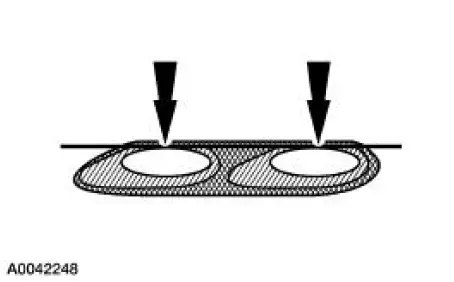

4. NOTE: This procedure should be done in a dark environment to effectively see the headlamp beam pattern.

Turn on the low beam headlamps to illuminate the wall or screen and open the hood.

5. NOTE: For SAE type headlamps, the appearance of the beam pattern may vary between vehicles.

On the wall or screen, locate the high intensity area of the beam pattern. Place the top edge of the high intensity zone even with the horizontal reference line.

VOR type headlamps

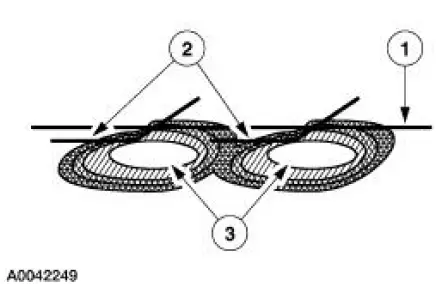

6. NOTE: The appearance of the VOR beam pattern may vary between vehicles.

Identify at the top edge of this high intensity area a distinct horizontal cutoff in the beam pattern.

If the top edge of this cutoff is not even with the horizontal reference line, the headlamp beam will need to be adjusted.

VOL type headlamps

7. For VOL type headlamps, there will be a distinct cutoff in the left portion of the beam pattern.

The edge of this cutoff should be positioned 50.2 mm (2 in) below the horizontal reference line.

1. Horizontal reference line.

2. Top edge of the beam pattern.

3. High intensity zone.

Mechanical Aiming

1. For the mechanical aiming procedure, refer to the appropriate mechanical headlamp aimer instruction manual.

Reversing Lamps

Reversing Lamps

Refer to Wiring Diagrams Cell 93 , Backup Lamps for schematic and

connector information.

Special Tool(s)

73III Automotive Meter or

equivalent

105-R0057

Inspection and Verification

...

Bulb - Headlamp

Bulb - Headlamp

Removal

WARNING: The halogen bulb contains gas under pressure. The bulb may

shatter if the

glass envelope is scratched or if the bulb is dropped. Handle the bulb only

by its base. Grasp

the bul ...

Other materials:

Brake Booster - Hydro-Boost (Removal and Installation)

Special Tool(s)

Installer Set, Teflon Seal

211-D027 (D90P-3517-A) or

equivalent

Removal

WARNING: The power brake booster should not be carried by the

accumulator, nor

should it ever be dropped on the accumulator. Check the snap ring on th ...

Reverse Sun Gear

Disassembly

1. Remove the reverse clutch sun gear assembly and the No. 4 forward clutch

hub bearing and

race.

2. Remove the forward clutch sun gear assembly and the No. 5 forward clutch

sun gear bearing

and race.

Assembly

1. The forward clutch ...

Keyless Entry/Computer Operated Locks

Programming -Keyless Entry Remote Transmitter

NOTE: All keyless entry remote transmitters (15K601) must be

programmed at the same time.

NOTE: All previous transmitter identification codes (TIC's) will be

erased when programming mode is

entered.

...