Ford Mustang (1999-2004) Service Manual: Inspection and Verification

1. Verify customer concern by running the engine.

2. Inspect the drive belt for chunking, fraying and wear.

3. Check the drive belt for correct routing.

Drive Belt Cracking/Chunking/Wear

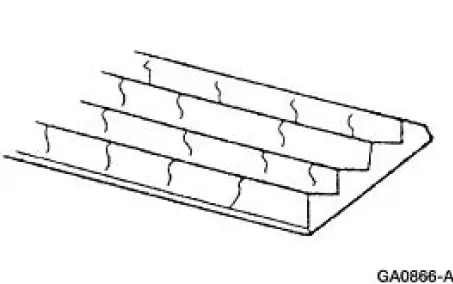

V Ribbed Serpentine Drive Belt With Cracks Across Ribs

The accessory drive:

- has a single serpentine drive belt.

- has an automatic drive belt tensioner.

- does not require adjustment.

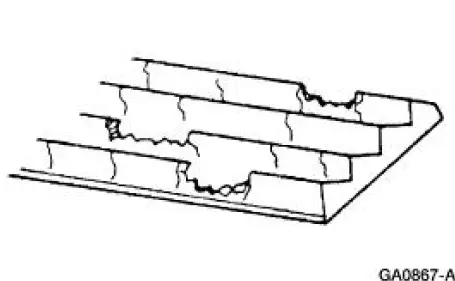

V Ribbed Belt With Chunks of Rib Missing

Symptom Chart

| Condition | Possible Sources | Action |

|

|

|

|

|

|

Component Tests

Component Tests

Drive Belt Noise/Flutter

Drive belt chirp occurs due to pulley misalignment or excessive pulley runout.

It can be the result of a

damaged pulley or an incorrectly aligned pulley.

To correct, determi ...

Other materials:

Tire Wear Chart

Wheel and tire NVH concerns are directly related to vehicle speed and are not

generally affected by

acceleration, coasting or decelerating. Also, out-of-balance wheel and tires can

vibrate at more than

one speed. A vibration that is affected by the engine ...

Steering System Symptom Definitions

Drift/Pull

Pull is a tugging sensation, felt by the hands on the steering wheel, that

must be overcome to keep the

vehicle going straight.

Drift describes what a vehicle with this condition does with hands off the

steering wheel.

A vehicle-related drift/p ...

Transmission Fluid Drain and Refill

Special Tool(s)

Automatic Transmission Flush

and Fill Machine

211-00018

Automatic Transmission Flush

and Fill Machine

199-00010 or equivalent

Material

Item

Specification

MERCON V Automatic

Transmission Fluid

XT-5-QM

M ...