Ford Mustang (1999-2004) Service Manual: Installation

1. Inspect the rear axle pinion flange seal journal for rust, nicks, and scratches prior to installing the flange. Polish the seal journal with fine crocus cloth, if necessary.

2. Lubricate the rear axle pinion flange splines.

- Use SAE 75W-140 High Performance Rear Axle Lubricant F1TZ-19580-B or equivalent meeting Ford specification WSL-M2C192-A.

3. NOTE: Disregard the index marks if installing a new rear axle pinion flange.

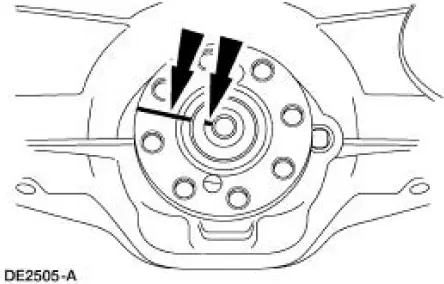

Position the rear axle pinion flange.

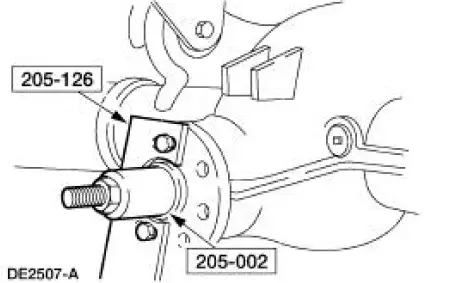

4. Using the special tools, install the rear axle pinion flange.

5. CAUTION: Do not under any circumstance loosen the nut to reduce preload. If it is necessary to reduce preload, install a new differential drive pinion collapsible spacer (4662) and nut.

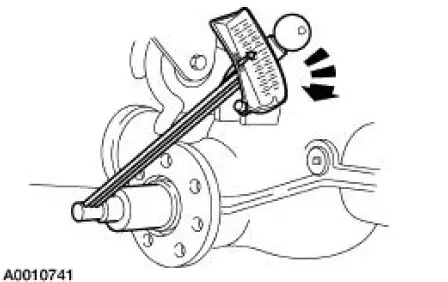

Tighten the nut to set the preload.

- Rotate the pinion occasionally to make sure the pinion bearings (4630) (4621) seat correctly. Take frequent pinion bearing torque preload readings by rotating the drive pinion gear with a Nm (inch/pound) torque wrench.

- If the preload recorded prior to disassembly is lower than the specification for used bearings, then tighten the nut to specification. If the preload recorded prior to disassembly is higher than the specification for used bearings, then tighten the nut to the original reading as recorded.

- Refer to the torque specification for used pinion bearings in the Specifications portion of this section.

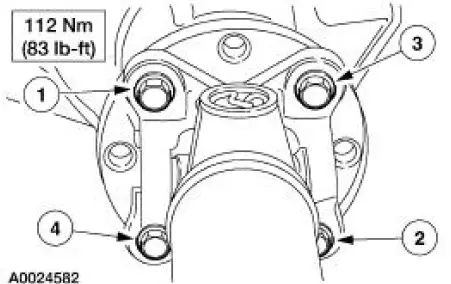

6. CAUTION: Align the index-marks.

CAUTION: Install the driveshaft with new bolts. If new bolts are not available, apply Threadlock and Sealer EOAZ-19554-AA or equivalent meeting Ford specification WSKM2G351- A5 to the threads of the original bolts.

CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. To make sure that the yoke seats squarely on the flange, tighten the bolts evenly in a cross pattern as shown.

Connect the driveshaft.

7. Install the rear brake calipers.

8. Install the rear wheel and tire assemblies.

9. Lower the vehicle.

Removal

Removal

1. Raise and support the vehicle.

2. Remove the rear wheel and tire assemblies.

3. CAUTION: Remove the rear brake calipers to prevent drag during the

drive pinion

bearing preload adjustment.

CAU ...

Pinion Seal

Pinion Seal

Special Tool(s)

Installer, Drive Pinion Oil Seal

205-133 (T79P-4676-A)

Removal

1. Remove the pinion flange (4851). For additional information, refer to

Drive Pinion Flange in this

sec ...

Other materials:

Removal

1. Remove the air intake scoop bracket. For additonal information, refer to

Section.

2. Remove the air cleaner outlet tube. For additional information, refer to

Section.

3. Disconnect the accelerator cable, the speed control actuator cable and the

return ...

Entertainment System - General Information

Audio System (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 130 , Radio for schematic and connector

information.

Special Tool(s)

73III Automotive Meter

105-R0057 or equivalent

Inspection and Verification

1. Verify the customer con ...

Idle Air Control (IAC) Valve - Mach I

Removal and Installation

1. Remove the air intake scoop. For additional

information, refer to Section.

2. Disconnect the idle air control (IAC) valve electrical connector.

3. Remove the bolts, the IAC valve and the gasket.

4. NOTE: Install a new ga ...