Ford Mustang (1999-2004) Service Manual: Removal

1. Raise and support the vehicle.

2. Remove the rear wheel and tire assemblies.

3. CAUTION: Remove the rear brake calipers to prevent drag during the drive pinion bearing preload adjustment.

CAUTION: Do not allow the calipers to hang from the brake hoses.

Remove the rear brake caliper and support bracket from the knuckle as an assembly. Wire the caliper and support bracket assembly out of the way.

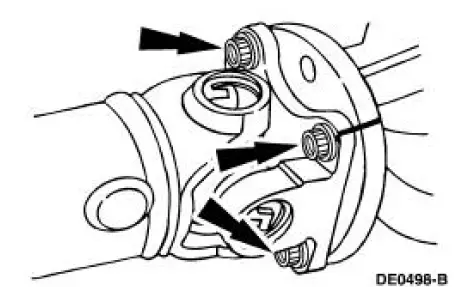

4. CAUTION: Index-mark the driveshaft flange and pinion flange (4851) to maintain initial balance during installation.

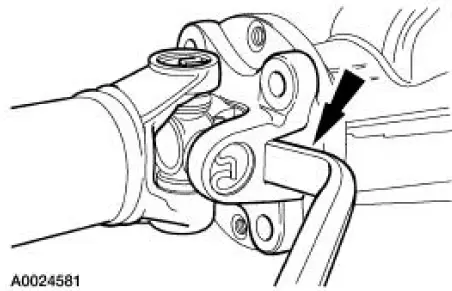

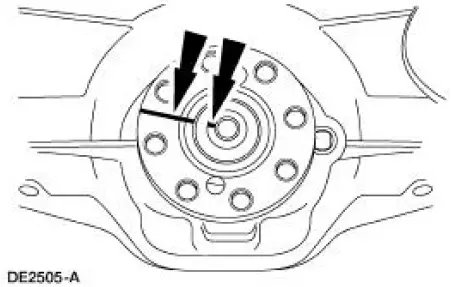

CAUTION: The driveshaft centering socket yoke fits tightly on the pinion flange pilot. Never hammer on the driveshaft or any of its components to disconnect the yoke from the flange. Pry only in the area shown, with a suitable tool, to disconnect the yoke from the flange.

Disconnect and position the driveshaft out of the way.

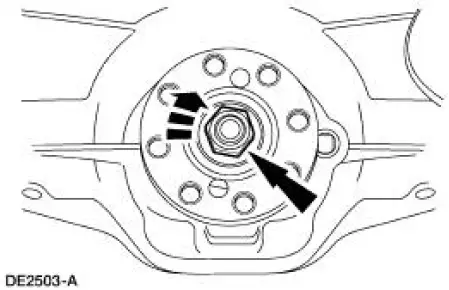

5. Install an Nm (inch/pound) torque wrench on the nut and record the torque necessary to maintain rotation of the drive pinion gear through several revolutions.

6. CAUTION: After removing the nut, discard it. Use a new nut for installation.

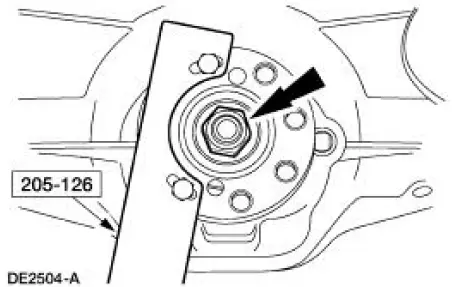

Use the special tool to hold the pinion flange while removing the nut.

7. Index-mark the pinion flange and drive pinion gear stem to maintain initial balance during installation.

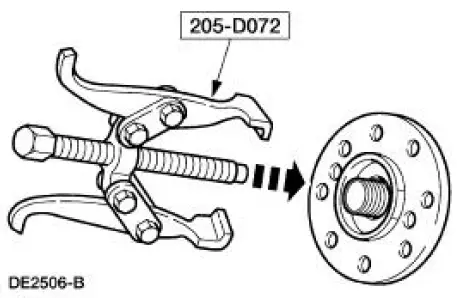

8. Using the special tool, remove the pinion flange.

Drive Pinion Flange and Drive Pinion Seal

Drive Pinion Flange and Drive Pinion Seal

Special Tool(s)

2-Jaw Puller

205-D072 (D97L-4221-A) or

equivalent

Holding Fixture, Drive Pinion

Flange

205-126 (T78P-4851-A)

Installer, Drive Pinion Flange

205-002 ...

Installation

Installation

1. Inspect the pinion flange seal journal for rust, nicks, and scratches

prior to installing the flange.

Polish the seal journal with fine crocus cloth, if necessary.

2. Lubricate the pinion flange ...

Other materials:

Transmission Case

Special Tool(s)

Handle

205-D055 (D81L-4000-A)

Installer, Bearing Cup

204-039 (T77F-1217-B)

Installer, Drive Pinion Bearing

Cup

205-054 (T71P-4616-A)

Installer, Rear Axle Oil Seal

205-155 (T80T-4000-Y)

...

Planetary Gear Support Assembly and Planetary One-Way

Clutch

Disassembly and Assembly

1. NOTE: Inspect the outer and inner races for scores or damaged

surface areas where rollers

contact the races. Inspect the rollers and springs for excessive wear or damage.

Inspect the

spring and cage for bent or damaged ...

Instrument Cluster Self-Diagnostic Mode

To enter the instrument cluster self-diagnostic mode, press and hold the

instrument cluster

SELECT/RESET button, turn the ignition switch to the RUN position, and then

continue pressing the

SELECT/RESET button (five seconds) until tESt is displayed in th ...