Ford Mustang (1999-2004) Service Manual: Removal

1. Remove brake master cylinder filler cap (2162). Check brake fluid level in brake master cylinder reservoir (2K478). Remove fluid until brake master cylinder reservoir is half full.

2. Raise and support the vehicle.

3. Remove the wheel and tire assembly. .

4. CAUTION: Install new pads if worn to or past the specified thickness above the metal backing plate or rivets. Install pads in complete axle sets.

Inspect the pads for wear and contamination.

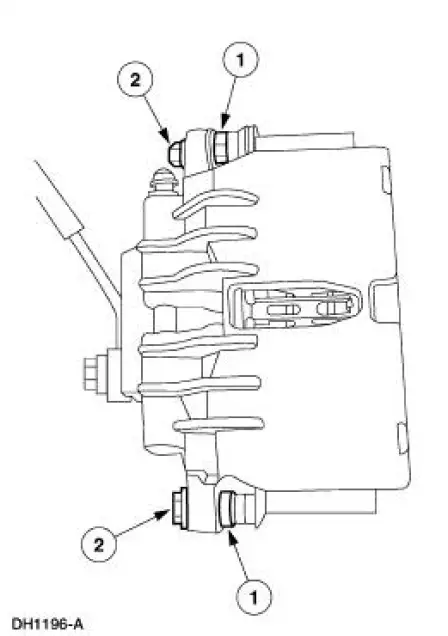

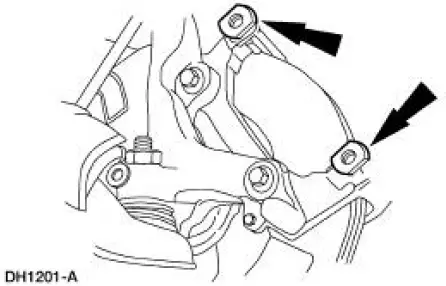

5. Remove the caliper bolts.

1. Hold the guide pins stationary.

2. Remove and discard the caliper bolts.

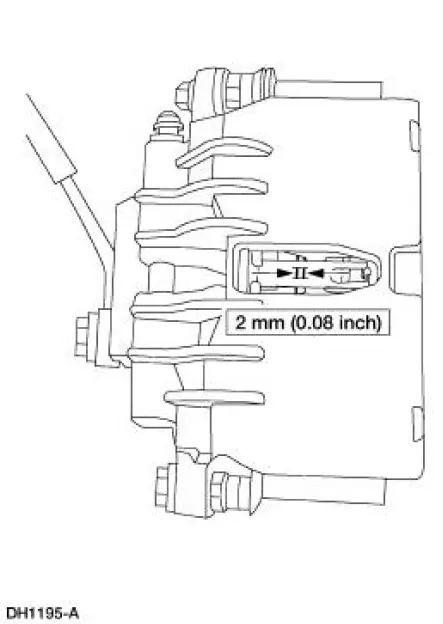

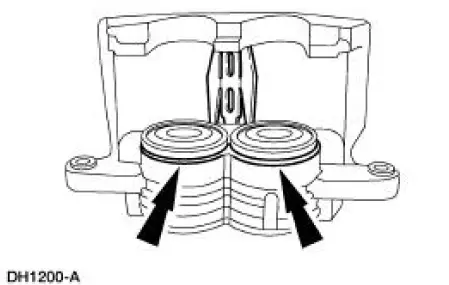

6. CAUTION: Do not pry in caliper sight hole to retract pistons as this can damage the pistons and boots.

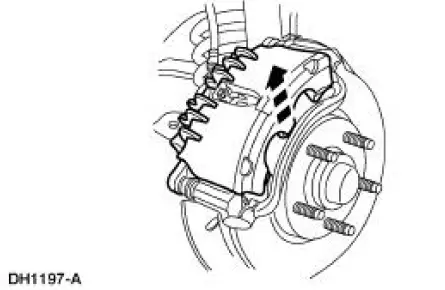

CAUTION: When removing the disc brake caliper (2B120), never allow it to hang from the brake hose. Provide a suitable support.

Lift the caliper off the anchor plate (2B292).

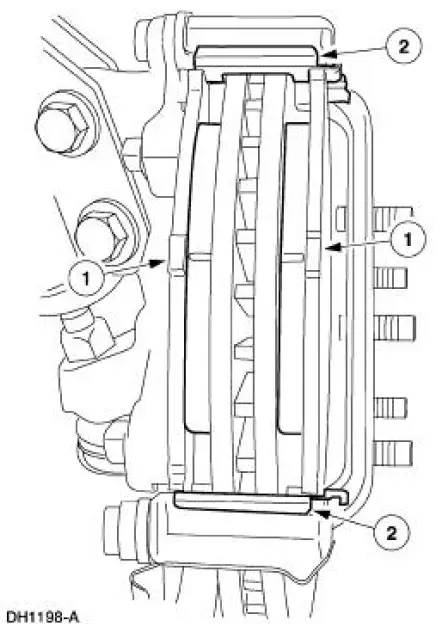

7. Remove the pads and the pad slippers.

1. Remove the pads and verify thickness.

2. Remove and discard slippers.

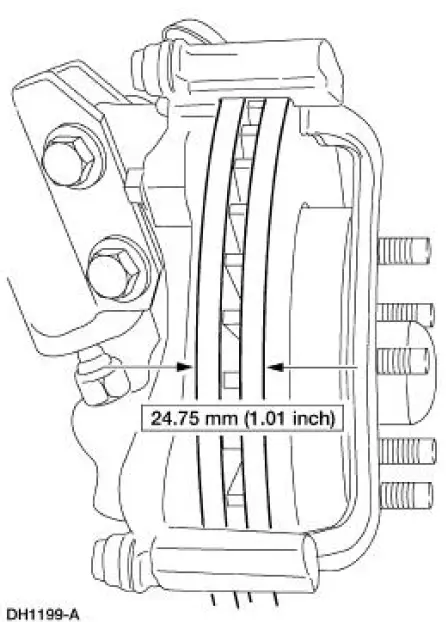

8. Measure the front brake disc thickness.

- Install a new front brake disc (1125) if not within specification.

9. Inspect the disc brake caliper.

- If leaks or damaged boots are found, disassembly is required. For additional information, refer to Caliper in this section.

10. Inspect the front disc brake anchor plate assembly.

- Check the guide pin boots for damage.

- Check the guide pins for binding and damage.

- Worn or damaged pins should be installed new.

Pads

Pads

...

Installation

Installation

1. CAUTION: Do not allow grease, oil, brake fluid or other

contaminants to contact the

pad lining material. Do not install contaminated pads.

NOTE: Install all hardware supplied with pad kits. ...

Other materials:

Removal

1. Remove the air intake scoop bracket. For additonal information, refer to

Section.

2. Remove the air cleaner outlet tube. For additional information, refer to

Section.

3. Disconnect the accelerator cable, the speed control actuator cable and the

return ...

Diagnostic Strategy

Troubleshooting an electronically controlled automatic transmission

is simplified by using the proven

method of diagnosis. One of the most important things to remember is

that there is a definite

procedure to follow.

NOTE: Do not take any short cut ...

Lower Arm

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number must be installed if installation becomes nec ...