Ford Mustang (1999-2004) Service Manual: Camshaft Roller Follower

Special Tool(s)

|

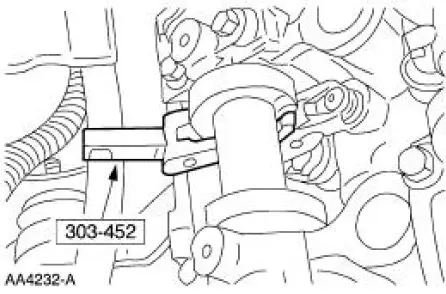

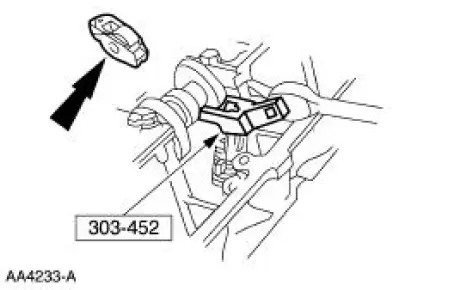

Compressor, Valve Spring (Intake) 303-452 (T93P-6565-AR) |

|

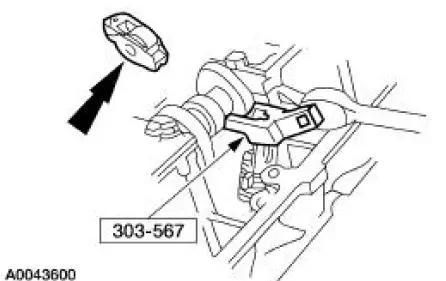

Compressor, Valve Spring (Exhaust) 303-567 (T97P-6565-AH) |

Removal

1. Remove the valve cover. For additional information, refer to Valve Cover LH or Valve Cover RH in this section.

2. Position the piston of the cylinder being serviced at the bottom of the stroke and the camshaft lobe at base circle.

3. Using the special tool compress the intake valve spring.

4. Remove the roller follower from the intake valve.

5. Using the special tool compress the exhaust valve spring.

6. Remove the camshaft roller follower from the exhaust valve.

7. Repeat Steps 2, 3 and 4 to remove all the necessary roller followers. Inspect roller finger followers and camshafts. For additional information, refer to Section.

Installation

1. To install, reverse the removal procedure.

Hydraulic Lash Adjuster

Hydraulic Lash Adjuster

Removal and Installation

1. Remove the roller followers. For additional information, refer to Camshaft

Roller Follower in this

section.

2. Remove the eight hydraulic lash adjusters.

3. Inspect the ...

Camshaft

Camshaft

Removal and Installation

1. Remove the timing chains. For additional information, refer to Timing

Drive Components in this

section.

2. Remove the roller followers. For additional information, refer ...

Other materials:

Transmission Fluid Drain and Refill

Special Tool(s)

Automatic Transmission Flush

and Fill Machine

211-00018

Automatic Transmission Flush

and Fill Machine

199-00010 or equivalent

Material

Item

Specification

MERCON V Automatic

Transmission Fluid

XT-5-QM

M ...

Instrument Panel and Console

Torque Specifications

Instrument Panel

The instrument panel consists of the following components:

instrument cluster

instrument panel finish panels

audio unit

A/C controls

glove compartment door

passenger air bag module

glove compart ...

Cleaning products

For best results, use the following products or products of equivalent

quality:

Motorcraft Bug and Tar Remover (ZC-42)

Motorcraft Custom Bright Metal Cleaner (ZC-15)

Motorcraft Detail Wash (ZC-3-A)

Motorcraft Dusting Cloth (ZC-24)

Motorcraft Engine Shampoo and ...