Ford Mustang (1999-2004) Service Manual: Sprockets

1. WARNING: To avoid the possibility of personal injury or damage to the vehicle, do not operate the engine with the hood open until the fan blade has been examined for possible cracks and separation.

NOTE: Specifications show the expected minimum or maximum condition. Refer to the appropriate section in Group 303 for the procedure.

NOTE: If a component fails to meet the specifications, it is necessary to install a new component or refinish. If the component can be refinished, wear limits are provided as an aid to making a decision. A new component must be installed for any component that fails to meet specifications and cannot be refinished.

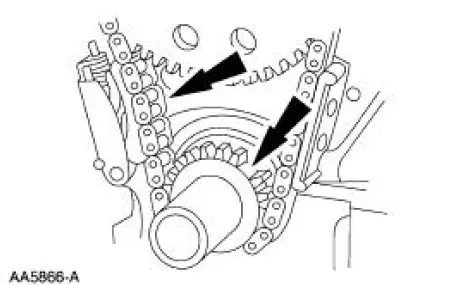

Inspect the timing chain/belt and the sprockets.

- Install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Rocker Arms - Cleaning

1. Clean all parts thoroughly. Make sure all oil passages are open.

2. Make sure oil passage in the push rod/valve tappet end of the rocker arm (6564) is open.

Component Tests

Component Tests

Engine Oil Leaks

NOTE: When diagnosing engine oil leaks, the source and location of

the leak must be positively

identified prior to repair.

Prior to carrying out this procedure, clean all sealin ...

Rocker Arms - Inspection

Rocker Arms - Inspection

CAUTION: Do not attempt to true surfaces by grinding. Check the

rocker arm pad, side

rails and seat for excessive wear, cracks, nicks or burrs. Check the rocker

arm seat bolt for

stripped or bro ...

Other materials:

Bypass Tube - 3.8L

Material

Item

Specification

Motorcraft Premium Gold

Engine Coolant

VC-7-A (in Oregon VC-7-B)

(yellow color)

WSS-M97B51-

A1

Removal and Installation

1. Drain the engine coolant. For additional information, refer to Cooling

System Dra ...

Getting the services you need

Warranty repairs to your vehicle must be performed by an authorized

dealer. While any authorized dealer handling your vehicle line will

provide warranty service, we recommend you return to your selling

authorized dealer who wants to ensure your continued satis ...

Anti-Theft - Passive Anti-Theft System (PATS) (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 112 , Anti-Theft for schematic and connector

information.

Refer to Wiring Diagrams Cell 60 , Instrument Cluster for schematic and

connector information.

Special Tool(s)

73III Automotive Meter

105-R0057 or equivalen ...