Ford Mustang (1999-2004) Service Manual: Rocker Arms - Inspection

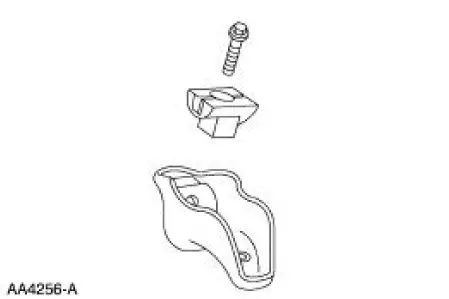

CAUTION: Do not attempt to true surfaces by grinding. Check the rocker arm pad, side rails and seat for excessive wear, cracks, nicks or burrs. Check the rocker arm seat bolt for stripped or broken threads. Install new components as ncessary or possible damage may occur.

1. Inspect the rocker arm push rod bore for nicks, scratches, scores or scuffs. Install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

2. Inspect the pad at the valve end of the rocker arm for indications of scuffing or abnormal wear. If the pad is grooved, install a new rocker arm. Refer to the appropriate section in Group 303 for the procedure.

Push Rods - Cleaning

1. Clean the push rods (6565) in a suitable solvent. Blow out the oil passage in the push rods with compressed air.

Sprockets

Sprockets

1. WARNING: To avoid the possibility of personal injury or damage

to the vehicle, do

not operate the engine with the hood open until the fan blade has been

examined for

possible cracks and separ ...

Push Rods - Inspection

Push Rods - Inspection

1. CAUTION: Do not attempt to straighten push rods.

Check the ends of the push rods for nicks, grooves, roughness or

excessive wear. Install new

push rods as necessary. Refer to the appropriate se ...

Other materials:

Sun visors

Slide-On-Rod

Rotate the visor toward the side

window and extend it rearward for

extra sunlight coverage.

Retract the visor before moving it

back toward the windshield and

storing it.

Illuminated Visor Vanity Mirror

Lift the cover to switch on the lamp.

Flex ...

General information on radio frequencies

This device complies with part 15 of the FCC Rules and with Industry

Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) This device may not cause harmful

interference, and (2) This device must accept any interferen ...

Torque Converter Turbine to Pump Stator Interference

Check

1. NOTE: Front pump support may remain in front pump support and gear

during this test.

Position the torque converter with the pump drive up.

2. Install the front pump support to engage the mating splines of the front

pump support shaft on

the torque convert ...