Ford Mustang (1999-2004) Service Manual: Connecting Rod - Side Clearance

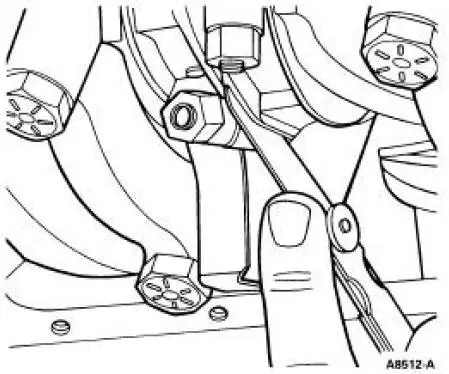

1. Measure the clearance between the connecting rod and the crankshaft. Verify the measurement is within specification.

- Refer to the appropriate section in Group for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group for the procedure.

Roller Follower -Inspection

Push rod engines

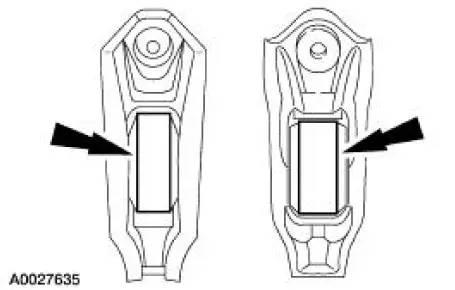

1. Inspect the roller for flat spots or scoring. If any damage is found, inspect the camshaft lobes and valve tappet for damage.

OHC engines

Valve Tappet -Inspection

Push rod engines

1. Inspect the hydraulic valve tappet and roller for damage. If any damage is found, inspect the camshaft lobes and valves for damage.

OHC engines

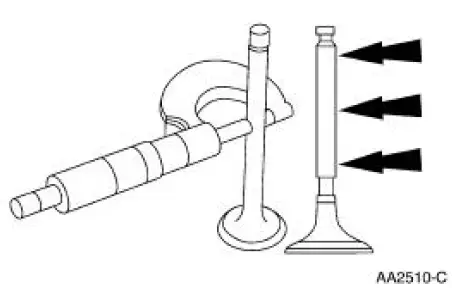

Valve -Stem Diameter

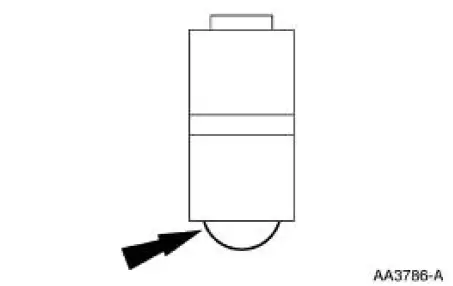

1. Measure the diameter of each intake and exhaust valve stem at the points shown. Verify the diameter is within specification.

- Refer to the appropriate section in Group for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group for the procedure.

Connecting Rod - Bearing Journal Clearance

Connecting Rod - Bearing Journal Clearance

Special Tool(s)

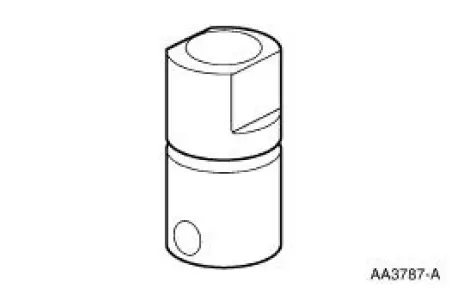

Plastigage

303-D031 (D81L-6002-B) or

equivalent

NOTE: The crankshaft connecting rod journals must be within

specifications to check the connecting

rod bearing journa ...

Valve Stem to Valve Guide Clearance

Valve Stem to Valve Guide Clearance

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Clearance Gauge, Valve Guide

303-004 (TOOL-6505-E) or

equivalent

NOTE: Valve ...

Other materials:

Installation

1. CAUTION: The actuator adjustment tool included with the

replacement actuator kit

must be used when installing the supercharger bypass vacuum actuator.

Failure to

correctly adjust the actuator will result in incorrect operation of the

supercharg ...

Exhaust Manifold LH

Special Tool(s)

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

Support Bar, Engine

303-290-A

Removal and Installation

1. Install the special tool.

2. Install the special tools.

3. Raise and support the vehicle. For additional ...

Disc and Pressure Plate - 3.8L and 4.6L (2V) Engines

Special Tool(s)

Clutch Aligner

308-020 (T74P-7137-K)

Material

Item

Specification

Premium Long Life Grease

XG-1-C

ESA-M1C75-B

1. Remove the transmission.

2. CAUTION: Loosen the bolts evenly to prevent clutch pressure plate

...