Ford Mustang (1999-2004) Service Manual: Turn Signal and Hazard Lamps

Refer to Wiring Diagrams Cell 90 , Turn/Stop/Hazard Lamps for schematic and connector information.

Special Tool(s)

|

73 III Automotive Meter 105-R0057 or equivalent |

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for the following obvious signs of mechanical and electrical damage.

Visual Inspection Chart

| Mechanical |

Electrical |

|

|

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

| Condition | Possible Sources | Action |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pinpoint Tests

PINPOINT TEST J: THE TURN SIGNAL LAMPS ARE NEVER ON

| Test Step | Result / Action to Take |

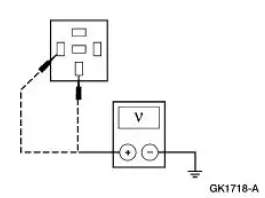

| J1 CHECK THE VOLTAGE TO THE ELECTRONIC FLASHER | Yes GO to J2 . No REPAIR the circuit in question. TEST the system for normal operation. |

|

|

| J2 CHECK CIRCUIT 44 (LB) | Yes GO to J3 . No REPAIR the circuit. TEST the system for normal operation. |

|

|

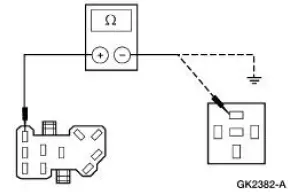

| J3 CHECK THE CONTINUITY OF THE MULTIFUNCTION SWITCH | Yes INSTALL a new electronic flasher. TEST the system for normal operation. No INSTALL a new multifunction switch. REFER to Section. TEST the system for normal operation. |

|

PINPOINT TEST K: THE HAZARD FLASHER LAMPS ARE NEVER ON

| Test Step | Result / Action to Take |

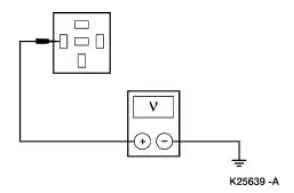

| K1 CHECK THE VOLTAGE TO THE ELECTRONIC FLASHER | Yes GO to K2 . No REPAIR the circuit. TEST the system for normal operation. |

|

|

| K2 CHECK CIRCUIT 385 (WH/RD) | Yes GO to K3 . No REPAIR the circuit. TEST the system for normal operation. |

|

|

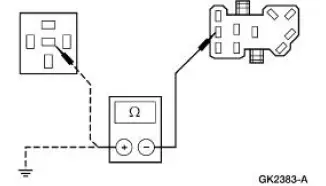

| K3 CHECK THE CONTINUITY OF THE MULTIFUNCTION SWITCH | Yes INSTALL a new electronic flasher. TEST the system for normal operation. No INSTALL a new multifunction switch; REFER to Section. TEST the system for normal operation. |

|

Stoplamps

Stoplamps

Refer to Wiring Diagrams Cell 90 , Turn/Stop/Hazard Lamps for

schematic and connector information.

Special Tool(s)

73III Automotive Meter or

equivalent

105-R0057

Inspection and Ve ...

Parking, Rear and License Lamps

Parking, Rear and License Lamps

Refer to Wiring Diagrams Cell 92 , Exterior for schematic and connector

information.

Special Tool(s)

73 III Automotive Meter or

equivalent

105-R0057

Inspection and Verification

1 ...

Other materials:

Symptom Chart

Condition

Possible Sources

Action

Dogtracking

Excessive rear

thrust angle.

Front or rear

suspension

components.

Drive axle

damaged.

CHECK the wheel alignment.

ADJUST as necessary

INSPE ...

Lumbar Motor

Removal and Installation

All vehicles

1. Remove the front seat. For additional information, refer to Seat-Front

Power in this section.

2. Disconnect the power seat track electrical connector.

3. Remove the four seat track bolts.

Vehicles with standar ...

Camshaft

Special Tool(s)

Holding Tool, Camshaft

303-446 (T93P-6256-AHR)

Material

Item

Specification

Super Premium SAE 5W-20

Engine Oil

XO-5W20-QSP or equivalent

WSS-M2C153-

H

...