Ford Mustang (1999-2004) Service Manual: Camshaft Runout

Special Tool(s)

|

|

Dial Indicator Gauge with Holding Fixture 100-002 (TOOL-4201-C) or equivalent |

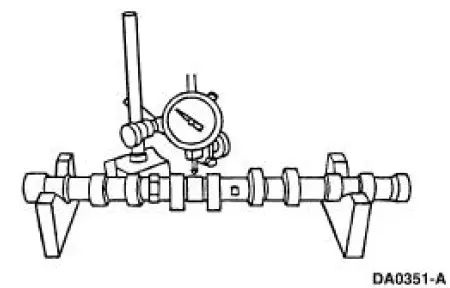

1. NOTE: Camshaft journals must be within specifications before checking runout.

Use a Dial Indicator Gauge with Holding Fixture to measure the camshaft runout.

- Rotate the camshaft and subtract the lowest indicator reading from the highest indicator reading.

- For additional information, refer to the specification chart in the appropriate engine section.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

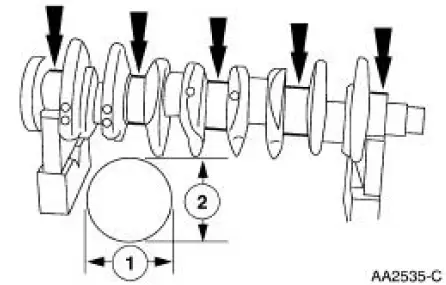

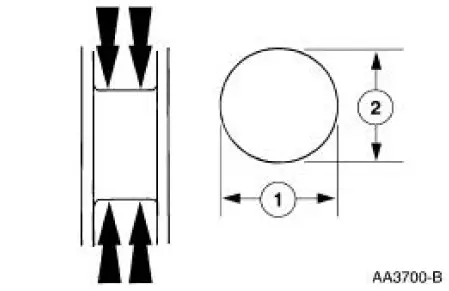

Crankshaft Main Bearing Journal -Diameter

1. Measure each of the crankshaft main bearing journal diameters in at least two directions.

- Refer to the appropriate section in Group 303 for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Crankshaft Main Bearing Journal -Taper

1. Measure each of the crankshaft main bearing journal diameters in at least two directions at each end of the main bearing journal.

- Refer to the appropriate section in Group 303 for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Camshaft Lobe Lift

Camshaft Lobe Lift

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

1. Use a Dial Indicator Gauge with Holding Fixture to measure camshaft

intake/exhaust ...

Crankshaft Main Bearing Journal - Clearance

Crankshaft Main Bearing Journal - Clearance

Special Tool(s)

Plastigage

303-D031 (D81L-6002-B) or

equivalent

NOTE: Crankshaft main bearing journals must be within specifications

before checking journal

clearance.

1. Remove th ...

Other materials:

Valve Cover LH

Material

Item

Specification

Silicone Gasket and Sealant

F7AZ-19554-EA or equivalent

WSE-M4G323-A4

Removal and Installation

1. Position the oil level tube (6754) out of the way.

2. Disconnect the breather tube.

3. Separate the engine wir ...

Installation

All vehicles

1. Position the engine front cover gasket on the engine front cover.

2. NOTE: If the engine front cover is not secured within four minutes, the

sealant must be removed

and the sealing area cleaned with metal surface cleaner. Allow to dry until ...

Pinpoint Test I: LFC 33/DTC B1933 - Passenger Air Bag Circuit Resistance

High

Normal Operation

The restraints control module (RCM) monitors the resistance of the

passenger air bag ignitor by

measuring the resistance between pins 6 and 7. If the RCM detects high

resistance between these

pins, it will store a diagnostic trouble cod ...