Ford Mustang (1999-2004) Service Manual: Cylinder Block Core Plug Replacement

Special Tool(s)

|

|

Slide Hammer 100-001 (T50T-100-A) |

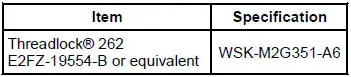

Material

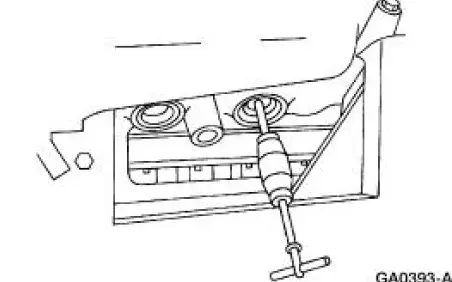

1. Use a slide hammer or tools suitable to remove the cylinder block core plug.

2. Inspect the cylinder block plug bore for any damage that would interfere with the correct sealing of the plug. If the cylinder block plug bore is damaged, bore for the next oversize plug.

3. NOTE: Oversize plugs are identified by the OS stamped in the flat located on the cup side of the plug.

Coat the cylinder block core plug and bore lightly with Threadlock 262 and install the cylinder block core plug.

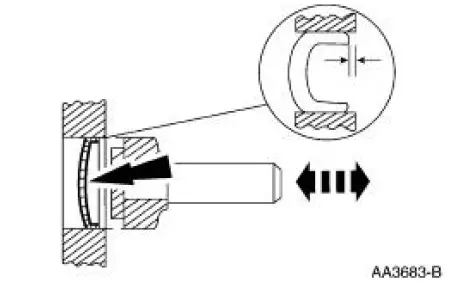

Cup-Type

4. CAUTION: Use care during this procedure so as not to disturb or distort the cup sealing surface.

CAUTION: When installed, the flanged edge must be below the chamfered edge of the bore to effectively seal the bore.

Use a tool suitable to seat the cup-type cylinder block core plug.

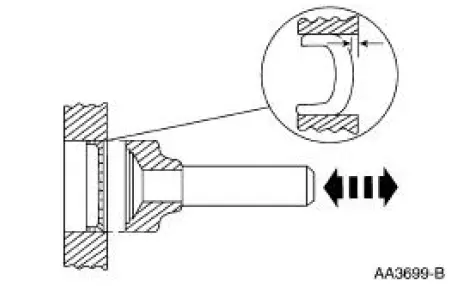

Expansion-Type

1. CAUTION: Do not contact the crown when installing an expansion-type cylinder block core plug. This could expand the plug before seating and result in leakage.

Use tool suitable to seat the expansion-type cylinder block core plug.

Spark Plug Hole Thread Repair

1. There is no authorized repair for spark plug hole threads. If the threads are damaged, install a new cylinder head.

Cylinder Head - Distortion

Cylinder Head - Distortion

Special Tool(s)

Straight Edge

303-D039 (D83L-4201-A) or

equivalent

1. Use a straight edge and a feeler gauge to inspect the cylinder head for

flatness. If the cylinder

head is disto ...

Spark Plug - Inspection

Spark Plug - Inspection

1. Inspect the spark plug for a bridged gap.

Check for deposit build-up closing the gap between the electrodes.

Deposits are caused

by oil or carbon fouling.

Clean the spark plug.

2. Ch ...

Other materials:

Clutch And Clutch Field Coil

Special Tool(s)

2-Jaw Puller

205-D026 (D80L-1002-L) or

equivalent

Installer, A/C Compressor Coil

412-065 (T89P-19623-EH)

Holding Fixture, Compressor

Clutch (3.8L vehicles)

412-098 (T94P-19703-AH)

Holding ...

Wheel Studs

Special Tool(s)

C-Frame and Clamp Assembly

211-023 (T74P-3044-A1)

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A ...

Retractor - Front Seat Safety Belt, Coupe

Special Tool(s)

Torx Bit, Safety Belt Bolt

501-010 (T77L-2100-A)

Removal

1. Remove the quarter trim panel (31012). For additional information, refer

to Section.

2. Using the special tool, remove the bolt and the safety belt retractor.

Remov ...