Ford Mustang (1999-2004) Service Manual: Spark Plug - Inspection

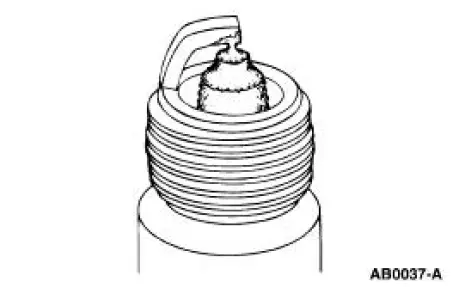

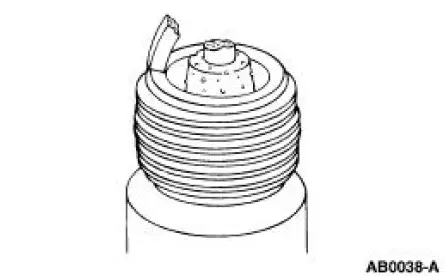

1. Inspect the spark plug for a bridged gap.

- Check for deposit build-up closing the gap between the electrodes. Deposits are caused by oil or carbon fouling.

- Clean the spark plug.

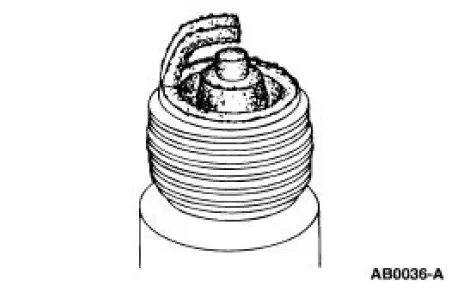

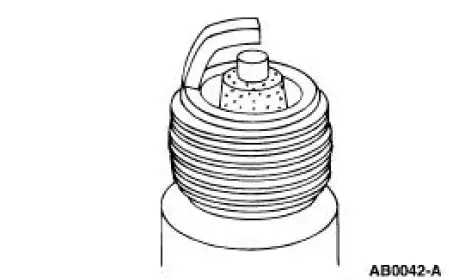

2. Check for oil fouling.

- Check for wet, black deposits on the insulator shell bore electrodes, caused by excessive oil entering the combustion chamber through worn rings and pistons, excessive valve-toguide clearance or worn or loose bearings.

- Correct the oil leak concern.

- Install a new spark plug.

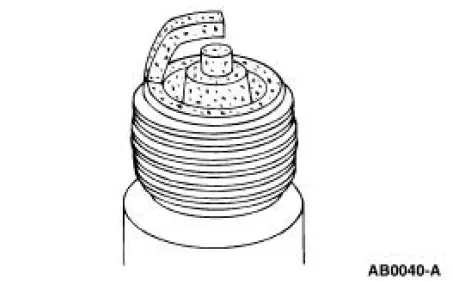

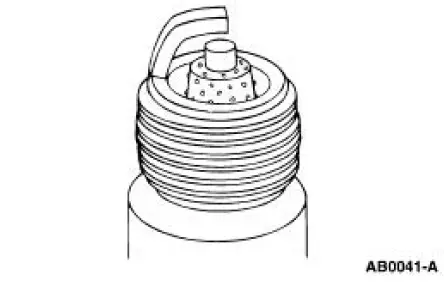

3. Inspect for carbon fouling. Look for black, dry, fluffy carbon deposits on the insulator tips, exposed shell surfaces and electrodes, caused by a spark plug with an incorrect heat range, dirty air cleaner, too rich a fuel mixture or excessive idling.

- Clean the spark plug.

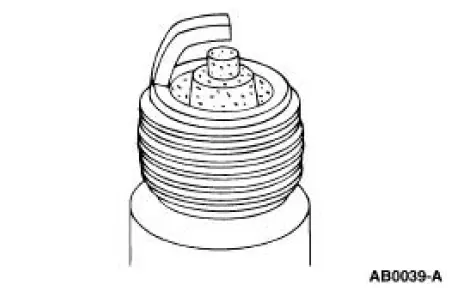

4. Inspect for normal burning.

- Check for light tan or gray deposits on the firing tip.

5. Inspect for pre-ignition, identified by melted electrodes and a possibly damaged insulator.

Metallic deposits on the insulator indicate engine damage. This may be caused by incorrect ignition timing, wrong type of fuel or the unauthorized installation of a heli-coil insert in place of the spark plug threads.

- Install a new spark plug.

6. Inspect for overheating, identified by a white or light gray spots and with bluish-burnt appearance of electrodes. This is caused by engine overheating, wrong type of fuel, loose spark plugs, spark plugs with an incorrect heat range, low fuel pump pressure or incorrect ignition timing.

- Install a new spark plug.

7. Inspect for fused deposits, identified by melted or spotty deposits resembling bubbles or blisters. These are caused by sudden acceleration.

- Clean the spark plug.

Cylinder Block Core Plug Replacement

Cylinder Block Core Plug Replacement

Special Tool(s)

Slide Hammer

100-001 (T50T-100-A)

Material

1. Use a slide hammer or tools suitable to remove the cylinder block core

plug.

2. Inspect the cylinder block plug bore f ...

Exhaust Manifold - Inspection

Exhaust Manifold - Inspection

Special Tool(s)

Straight Edge

303-D039 (D83L-4201-A) or

equivalent

1. Place a straight edge across the exhaust manifold flanges and check for

warping with a feeler

gauge.

Bearing ...

Other materials:

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical and electrical damage.

Visual Inspection Chart

Mechanical

Electrical

Fuel tank

Engine coolant level

Accessory drive belt

Engine oil level

Par ...

Front Subframe - 4.6L (4V) Engine

Special Tool(s)

3-Bar Engine Support Kit

303-F072

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

Removal and Installation

All vehicles

1. Remove the steering gear. For additional information, refer to Section .

2. Remove the low ...

Hydro-Boost Bleeding

1. NOTE: The Hydro-Boost power brake booster (2B560) is generally

self-bleeding, and the

following procedure will normally bleed the air from the power brake booster.

Normal operation

of the vehicle will further remove any additional trapped air.

Fill the p ...