Ford Mustang (1999-2004) Service Manual: Disassembly

1. Remove the differential assembly from the differential housing. For additional information, refer to Differential Case in this section.

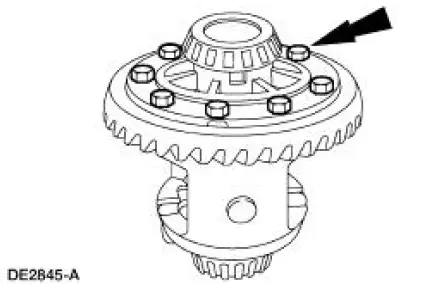

2. Remove the 10 bolts.

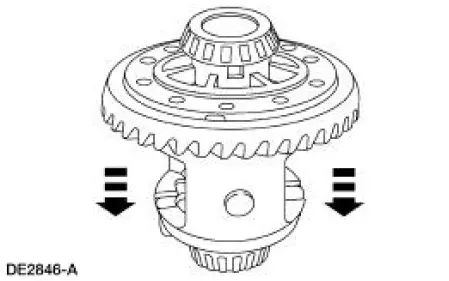

3. CAUTION: Do not damage the threads in the bolt holes.

Insert a punch in the bolt holes, and drive off the ring gear.

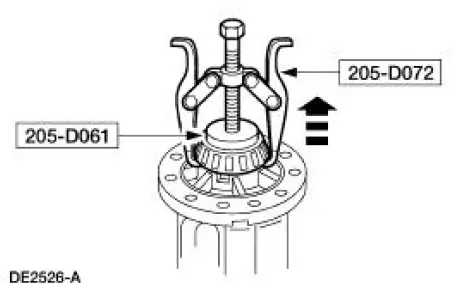

4. Using the special tools, remove the differential bearings (4221), if necessary.

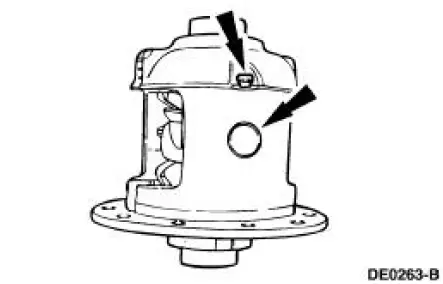

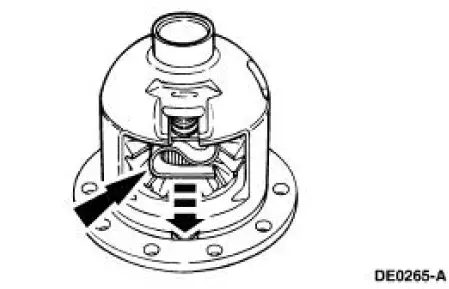

5. Remove the bolt and the differential pinion shaft (4211).

6. WARNING: Due to the spring tension, use care when removing the differential clutch spring (4214). Failure to follow these instructions may result in personal injury.

Remove the differential clutch spring.

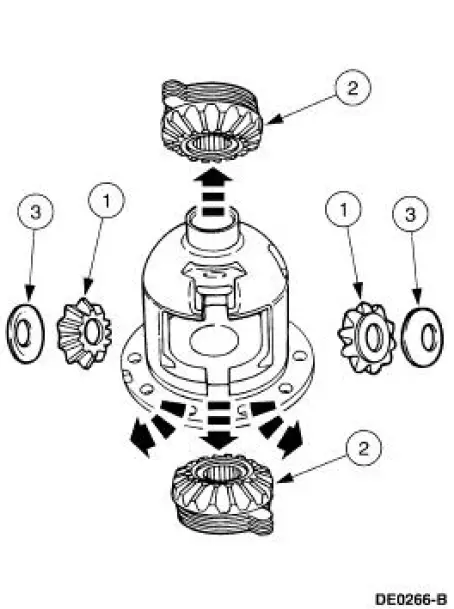

7. Remove the differential gears.

1. Remove the two differential pinion gears (4215).

2. Remove the two differential side gears (4236).

3. Remove the two differential pinion thrust washers (4230).

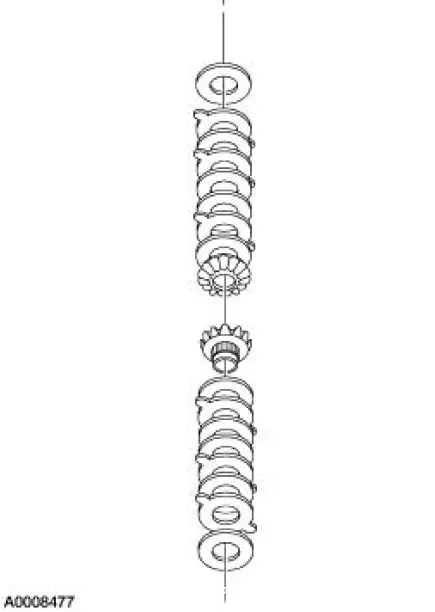

8. CAUTION: Keep the differential clutch packs (4947) in order. Do not mix them.

Always reassemble them in the same sequence.

Separate the differential clutch packs and shims from the differential side gears and tag them "right" and "left".

- Clean and inspect the remaining differential components for wear and damage and install new parts as necessary.

9. CAUTION: Do not use acids or solvents when cleaning the differential clutch pack.

Wipe components only with a clean, lint-free cloth.

Clean and inspect the differential clutch packs for wear and damage and install new parts as necessary.

Differential Case and Ring Gear - Traction-Lok

Differential Case and Ring Gear - Traction-Lok

Special Tool(s)

2-Jaw Puller

205-D072 (D97L-4221-A) or

equivalent

Gauge, Differential Clutch

205-022 (T66L-4204-A)

Gauge, Differential Clutch

205-135 (T80P-4946-A)

...

Assembly

Assembly

1. CAUTION: 118 ml (4 oz) of the specified Ford Friction Modifier must

be used in the

axle.

Lubricate each steel clutch plate and soak all friction plates for no less than

15 minutes.

Use Additiv ...

Other materials:

Air Conditioning (A/C) System Recovery, Evacuation and Charging

Special Tool(s)

R-134a A/C Refrigerant Center

176-00002 or equivalent

R-134a A/C Refrigerant Center

023-00153 or equivalent

R-134a Manifold Gauge Set

176-R032A or equivalent

1.2 CFM Vacuum Pump

023-00162 o ...

Installation

1. Install the upper intake manifold gasket.

2. Install the intake manifold and bolts in the sequence shown.

3. Install the PCV valve-to-intake manifold tube.

4. Connect the vacuum hoses and the electrical connector to the EGR vacuum

regulator soleno ...

Evaporative Emissions (Diagnosis and Testing)

Special Tool(s)

Evaporative Emission System

Leak Tester

310-F007 (134-00056) or

equivalent

Worldwide Diagnostic System

(WDS)

418-F224,

New Generation STAR (NGS)

Tester

418-F052, or equivalent scan

tool

Evaporative Em ...