Ford Mustang (1999-2004) Service Manual: Assembly

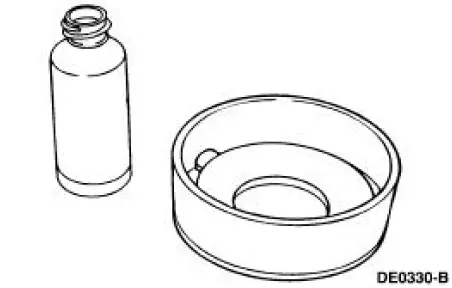

1. CAUTION: 118 ml (4 oz) of the specified Ford Friction Modifier must be used in the axle.

Lubricate each steel clutch plate and soak all friction plates for no less than 15 minutes.

- Use Additive Friction Modifier C8AZ-19B546-A or equivalent meeting Ford specification EST-M2C118-A

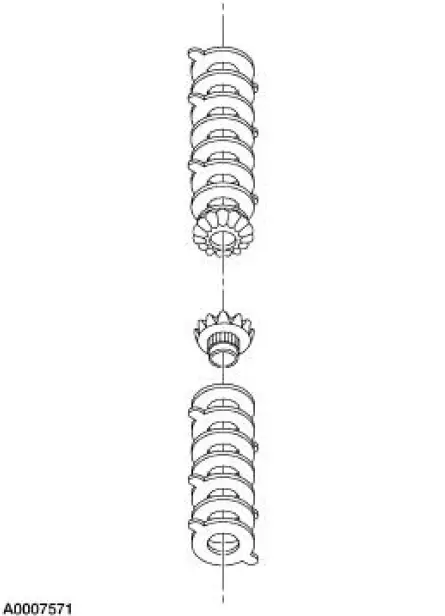

2. CAUTION: Do not mix the differential clutch packs or shims from one side with the other.

Assemble the differential clutch packs (without the shims) on their respective differential side gears.

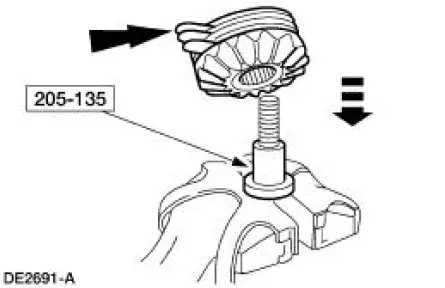

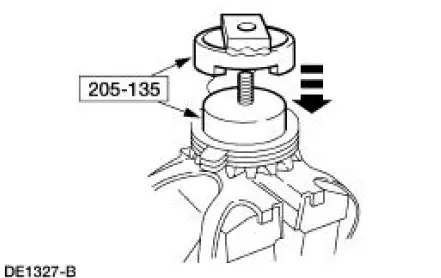

3. Place the base portion of the special tool in a vise. Install the differential differential side gear and differential clutch pack (without the shim) on the tool.

4. Position the special tool hand-tight on top of the differential clutch pack.

5. Install the special tool over the disc and differential clutch pack.

6. Install the nut.

7. NOTE: Clutch Pack Rebuild Kit F5AZ-4947-A is available for this application.

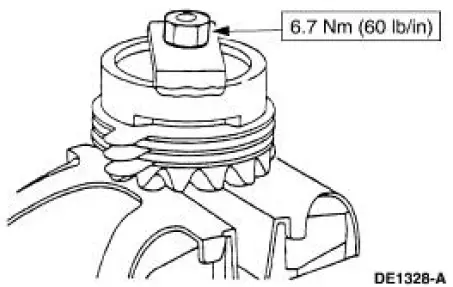

Select and insert the thickest feeler gauge blade that will enter between the tool and the differential clutch pack. The reading will be the thickness of the new clutch shim.

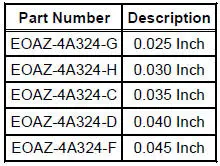

Selective Shims

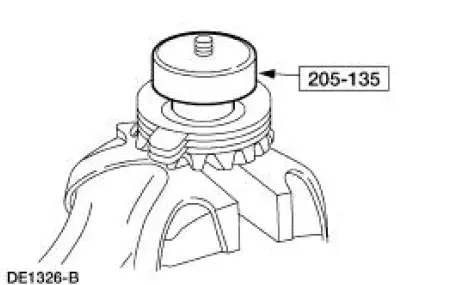

8. Remove the special tools from the differential clutch pack and differential side gear assembly.

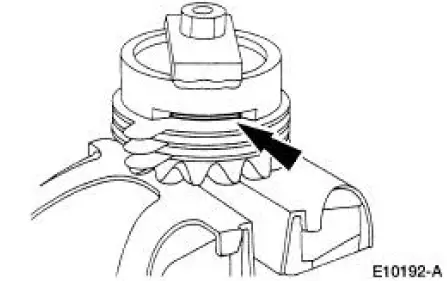

9. Install shim(s) on the differential clutch pack and differential side gear assembly.

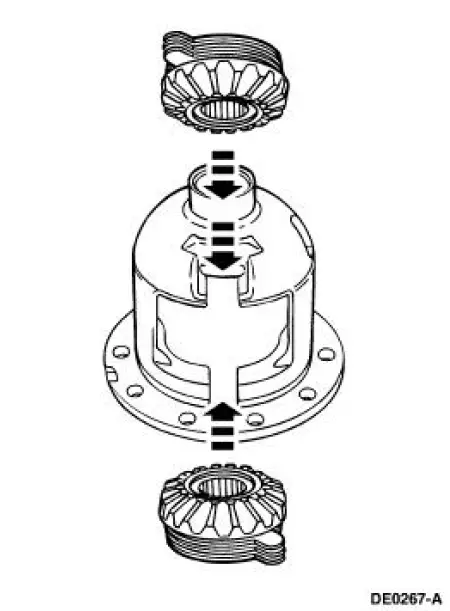

10. Install the differential side gear assemblies in the differential case.

11. Install the differential pinion gear and differential pinion thrust washer assemblies in the differential case.

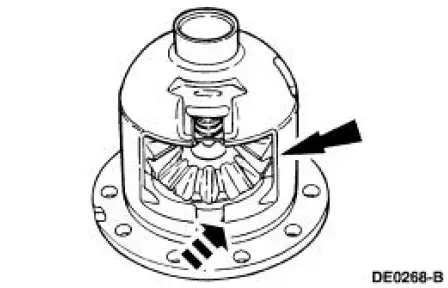

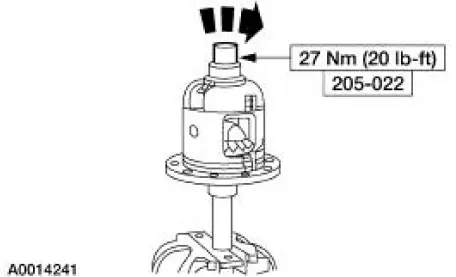

12. Using a soft-faced hammer, install the differential clutch spring.

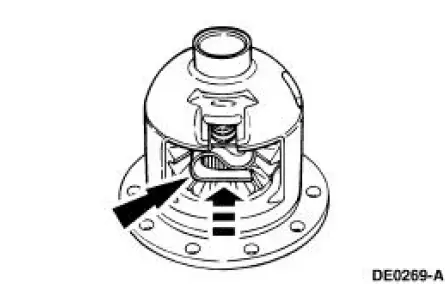

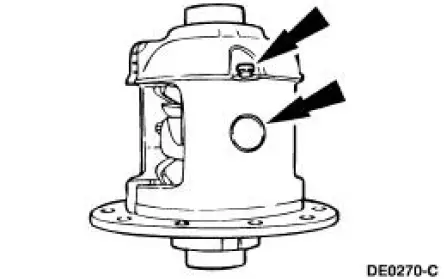

13. Install the differential pinion shaft and install a new bolt finger-tight.

14. Mount the differential case and the special tool in a vise. Using the special tool, check the torque necessary to rotate one differential side gear.

- If reusing the original clutch plates, the initial minimum break-away torque must be no less than the specification. The minimum rotating torque necessary to keep the differential side gear turning with new clutch plates may vary.

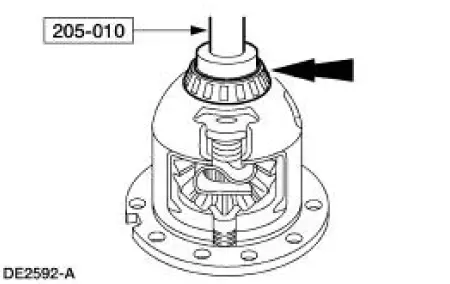

15. Using the special tool, install the differential bearings, if removed.

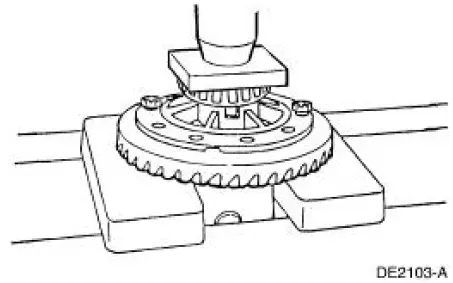

16. Position the differential ring gear and the differential case. Align the bolt holes by starting two bolts through the holes in the differential case and the differential ring gear. Press the differential ring gear on the differential case.

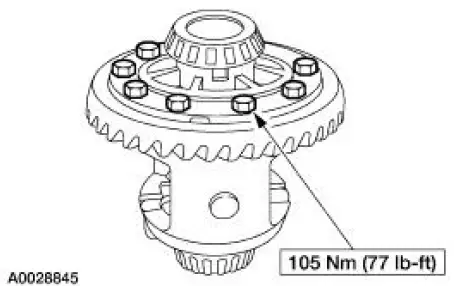

17. Install the bolts.

- Apply Stud and Bearing Mount EOAZ-19554-BA or equivalent meeting Ford specification WSK-M2G349-A1 to the bolt threads.

18. Install the differential assembly in the differential housing. For additional information, refer to Differential Case in this section.

Disassembly

Disassembly

1. Remove the differential assembly from the differential housing. For

additional information, refer

to Differential Case in this section.

2. Remove the 10 bolts.

3. CAUTION: Do not damage the thr ...

Rear Drive Axle/Differential - Ford 8.8-Inch IRS

Rear Drive Axle/Differential - Ford 8.8-Inch IRS

General Specifications

Torque Specifications

a: Use Stud and Bearing Mount EOAZ-19554-BA or equivalent meeting Ford

specification WSKM2G349-

A1.

b: With pinion flange yoke seal. ...

Other materials:

Inspection and Verification

1. Verify the customer's concern by operating the active restraint system to

duplicate the condition.

2. Inspect to determine if any of the following mechanical or electrical

concerns apply:

Visual Inspection Chart

Mechanical

Electrical

...

Leakage Inspection

CAUTION: Do not try to stop the fluid leak by increasing the torque

beyond specifications.

This may cause damage to the case threads.

Check the fluid filler tube connection at the transmission case. If

leakage is found here, install a new

grommet.

Ch ...

Spring

Special Tool(s)

Tie-Rod End Remover

211-001 (TOOL-3290-D) or

Equivalent

Coil Spring Compressor

204-D001 (D78P-5310-A) or

Equivalent

...