Ford Mustang (1999-2004) Service Manual: Exhaust Manifold RH

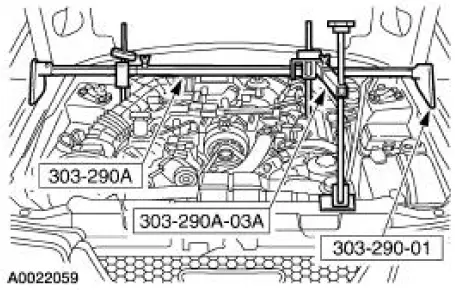

Special Tool(s)

|

Lifting Bracket, Engine 303-D088 (D93P-6001-A2) |

|

Support Bar, Engine 303-290-A |

Removal and Installation

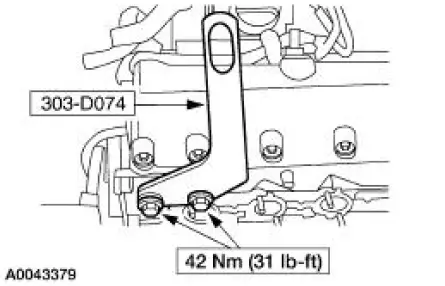

1. Install the special tool.

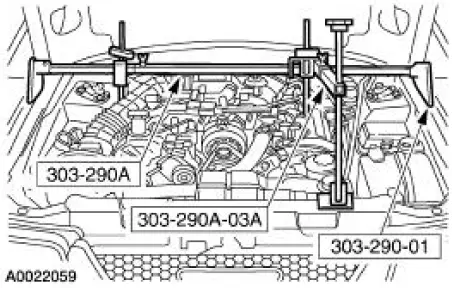

2. Install the special tools.

3. Raise and support the vehicle. For additional information, refer to Section.

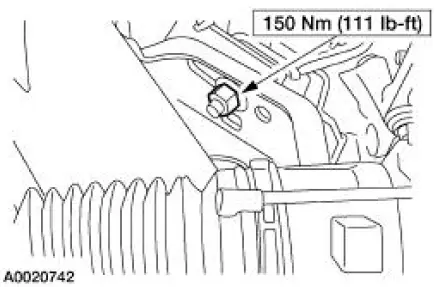

4. Remove the LH and RH side engine mount nuts.

5. Lower the vehicle.

6. Using the special tools, raise the engine.

7. Remove the air cleaner outlet tube. For additional information, refer to Section.

8. Raise and support the vehicle.

9. Remove the starter motor. For additional information, refer to Section.

10. Separate the exhaust at the exhaust manifold. For additional information, refer to Section.

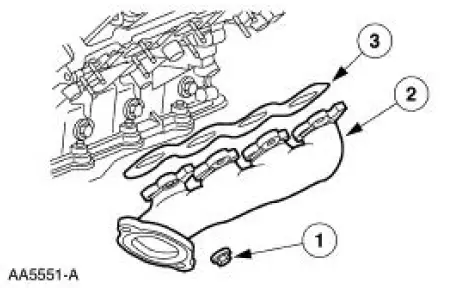

11. Remove the exhaust manifold.

1. Remove the exhaust manifold nuts.

2. Remove the exhaust manifold.

3. Remove the exhaust manifold gasket and discard.

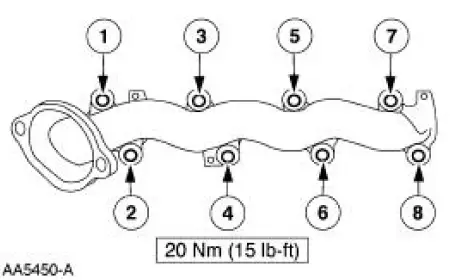

12. NOTE: Tighten the exhaust manifold nuts in the sequence shown.

To install, reverse the removal procedure.

Camshaft

Camshaft

Removal and Installation

1. Remove the timing chains. For additional information, refer to Timing

Drive Components in this

section.

2. Remove the roller followers. For additional information, refer ...

Exhaust Manifold LH

Exhaust Manifold LH

Special Tool(s)

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

Support Bar, Engine

303-290-A

Removal and Installation

1. Install the special tool.

2. Install the speci ...

Other materials:

Engine coolant check

Checking the Engine Coolant

The concentration and level of engine coolant should be checked at the

intervals listed in Scheduled Maintenance Information.

Note: Make sure that the level is at the FULL COLD level or within the

COLD FILL RANGE in the coolant res ...

Valve - Seat Inspection

Valve and Seat Refacing Measurements

CAUTION: After grinding valves or valve seats, check valve

clearance.

1. Check the valve head and seat.

Check valve angles.

Check margin width.

Refer to the appropriate section in Group 303 for the procedure.

...

Runout Check - Brake Disc and Hub

Special Tool(s)

Brake Measurement Kit

134-R0199 or equivalent

Material

Item

Specification

High Temperature Nickel Anti-

Seize Lubricant

F6AZ-9L494-AA

ESE-M12A4-

A

CAUTION: The brake disc (1126) runout specification must ...