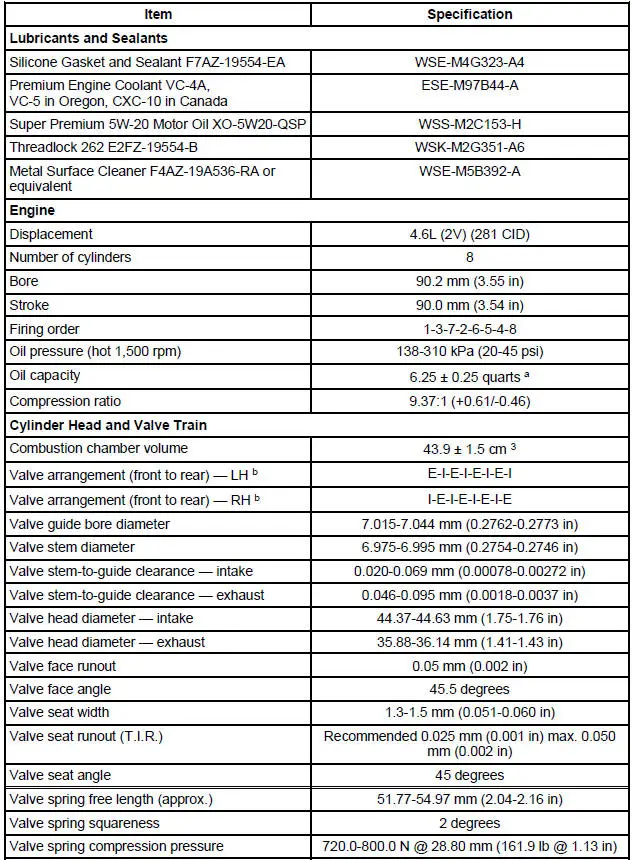

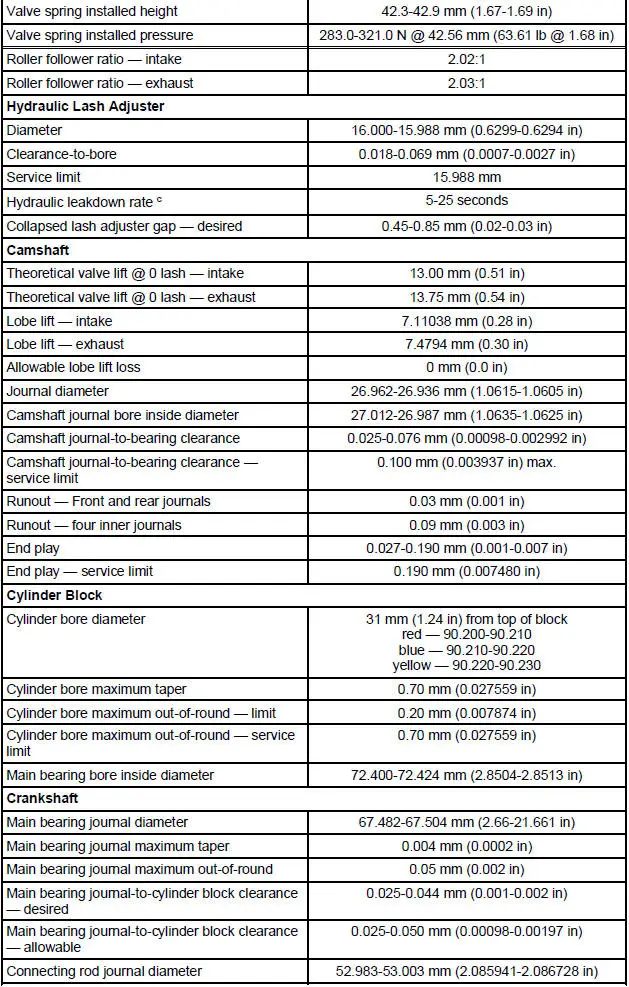

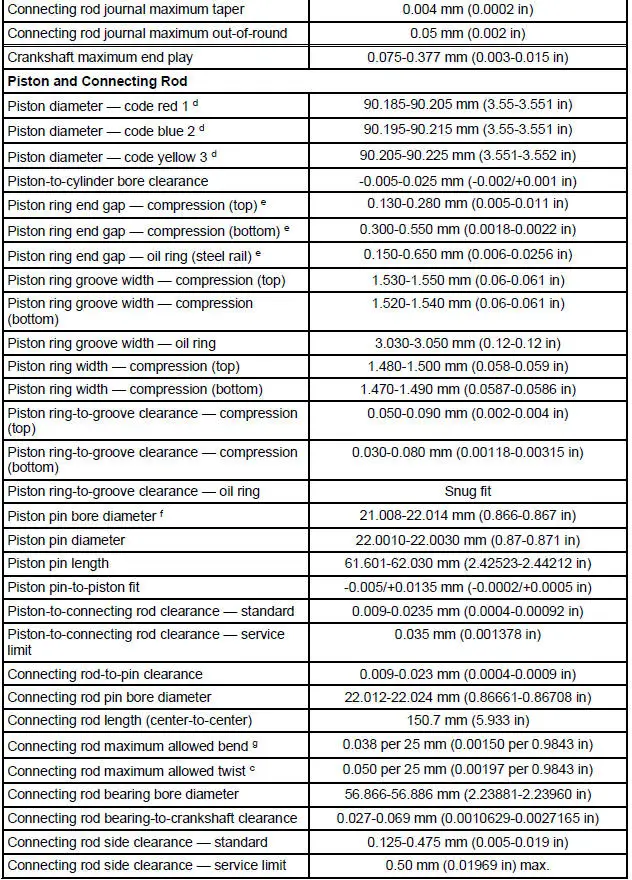

Ford Mustang (1999-2004) Service Manual: Engine - 4.6L (2V)

General Specifications

a - With installation of a new filter.

b - Distance front edge of bearing is installed below front face of cylinder block.

c - Time necessary for plunger to leak down 1.6 mm of travel with 222 N force and leak down fluid in tappet.

d - Measured at 31.5 mm from top of block. Measured at 43 mm from top of piston, at 90 degrees to the piston pin.

e - Specification in 90.200 mm diameter gauge.

f - If applicable, measured vertically, +0.030-0.050 mm (0.001-0.002 inch) measured horizontally (oval pin bore).

g - Pin bore and crank bearing bore must be parallel and in same vertical plane within the specified total difference when measured at the ends of a 203 mm bar, 101.5 mm on each side of rod centerline.

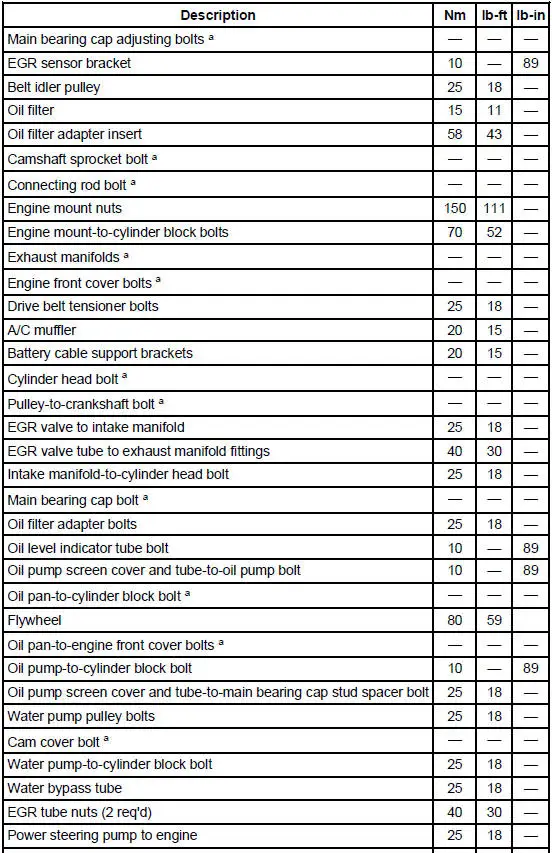

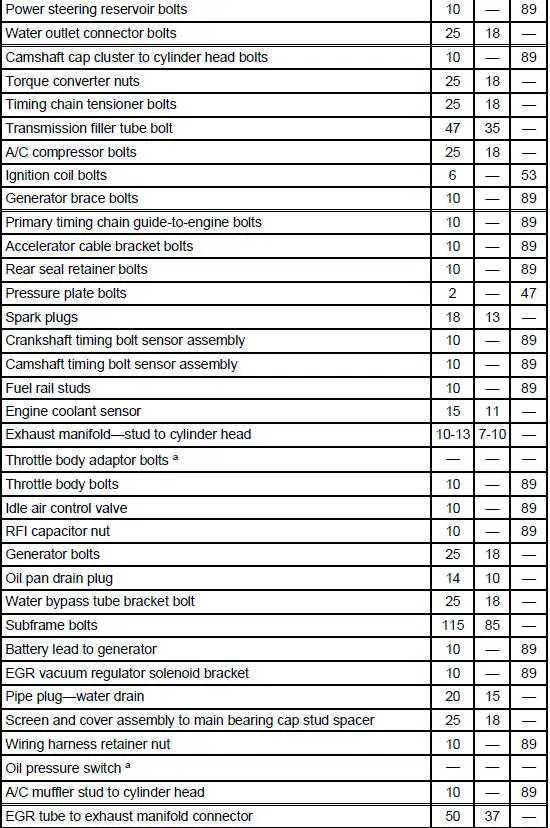

Torque Specifications

a - Refer to the procedure in this section.

- Engine

- Intake Manifold

- Valve Cover RH

- Valve Cover LH

- Crankshaft Pulley

- Crankshaft Front Oil Seal

- Engine Front Cover

- Timing Drive Components

- Valve Seals

- Hydraulic Lash Adjuster

- Camshaft Roller Follower

- Camshaft

- Exhaust Manifold RH

- Exhaust Manifold LH

- Oil Filter Adapter

- Oil Level Indicator and Tube

- Oil Pan

- Flywheel

- Flexplate

- Engine Mount RH

- Engine Mount LH

- Cylinder Heads (Removal)

- Engine (Removal)

- Engine (Disassembly)

- Cylinder Head (Disassembly and Assembly of Subassemblies)

- Piston

- Engine (Assembly)

- Cylinder Heads (Installation)

- Engine (Installation)

Engine (Installation)

Engine (Installation)

Special Tool(s)

Heavy Duty Floor Crane

014-00071 or equivalent

Spreader Bar

303-D089 (D93P-6001-A3) or

equivalent

Material

Item

Specification

SAE 5W-20 Pre ...

Engine

Engine

A modular engine is built around four modules:

the intake module

the cylinder head module (RH)

the cylinder head module (LH)

the lower engine module

While no ...

Other materials:

Synchronizers

Disassembly and Assembly

NOTE: This procedure applies to all synchronizer assemblies.

1. Scribe an alignment mark on the sliding sleeve and the hub for assembly

reference.

2. Remove the sliding sleeve, then remove the synchronizer struts and the

springs.

3 ...

Navigation controls

Type 1

WARNING: Driving while distracted can result in loss of vehicle

control, crash and injury. We strongly recommend that you use

extreme caution when using any device that may take your focus off

the road. Your primary responsibility is the safe operation ...

Audio Unit (Removal and Installation)

Removal and Installation

1. Remove the instrument panel center finish panel. For additional

information, refer to Section

2. Remove the audio unit.

1. Remove the screws.

2. Disconnect electrical connectors.

3. Disconnect antenna cable.

...