Ford Mustang (1999-2004) Service Manual: Frame and Mounting

Frame and Body Mounting

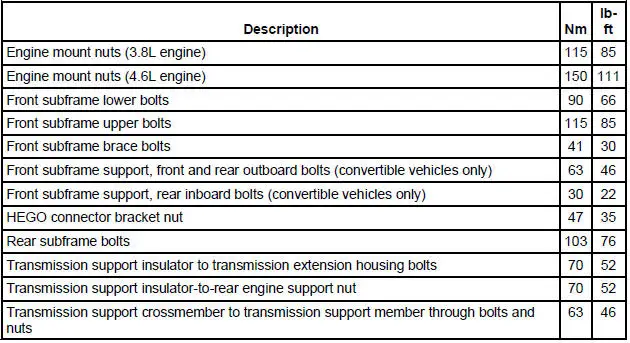

Torque Specifications

Frame Assembly

Underbody misalignment can affect front and rear wheel alignment, the operation of the suspension parts and drivetrain operation. Window glass cracks, door and window opening concerns, and air or water leaks at the doors are often caused by improperly tightened bolts and body misalignment.

Every structural member and outer panel is designed to offer the maximum protection in the event of a collision.

Body Misalignment Check

1. CAUTION: Do not attempt to correct any serious misalignment with one pulling/pushing operation. Damage to structure may occur.

NOTE: All body alignment measurements are made without trim and from metal to metal.

To check the body alignment, take two opposite diagonal measurements between the front, center or rear pillars. Take the measurements between reference points, such as crease lines or weld joints which are diagonally opposite each other on the two pillars being measured.

- Underbody Misalignment Check

- Front Subframe - 3.8L Engine

- Front Subframe - 4.6L (2V) Engine

- Front Subframe - 4.6L (4V) Engine

- Rear Subframe

Installation

Installation

WARNING: To reduce the risk of serious personal injury, read

and follow all warnings,

cautions and notes at the beginning of the removal procedure.

Vehicles receiving a new clockspring

1. NOT ...

Underbody Misalignment Check

Underbody Misalignment Check

Underbody Dimensions

1. Underbody dimensions tolerances are +- 3.175 mm (0.125 in). Reference

dimensions are not

controlled dimensions. Reference points are +- 4.76 mm (0.1875 in). All und ...

Other materials:

Inspection and Verification

WARNING: When servicing starter motor or carrying out other underhood

work in the

vicinity of the starter motor, be aware that the heavy gauge battery input lead

at the starter

solenoid is "electrically hot" at all times. A protective cap or boot is

provide ...

Steering System Symptom Definitions

Drift/Pull

Pull is a tugging sensation, felt by the hands on the steering wheel, that

must be overcome to keep the

vehicle going straight.

Drift describes what a vehicle with this condition does with hands off the

steering wheel.

A vehicle-related drift/p ...

Refueling

WARNING: Fuel vapor burns violently and a fuel fire can cause

severe injuries. To help avoid injuries to you and others:

• Read and follow all the instructions on the pump island.

• Turn off your engine when you are refueling.

• Do not smoke if you are n ...