Ford Mustang (1999-2004) Service Manual: Installation

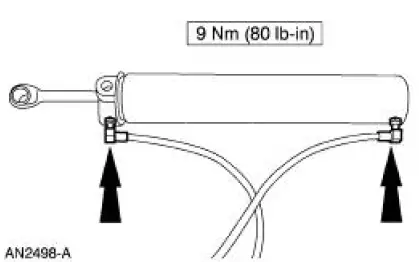

Lift cylinder

1. NOTE: Be sure that each fitting is installed in the correct position on the folding top hydraulic component.

NOTE: Make sure that the tetra seal is installed in the bottom of each of the folding top hydraulic cylinder ports before attaching the upper and lower hose fittings.

Install the hydraulic lines using a thread locker onto the lift cylinder.

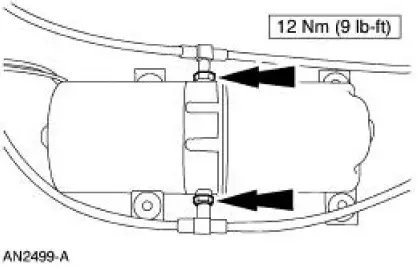

Motor assembly

2. NOTE: Be sure that each fitting is installed in the correct position on the folding top hydraulic component.

Install the hydraulic lines using a thread locker onto the motor assembly.

Hydraulic system

3. Bleed the hydraulic system. For additional information, refer to System Bleeding in this section.

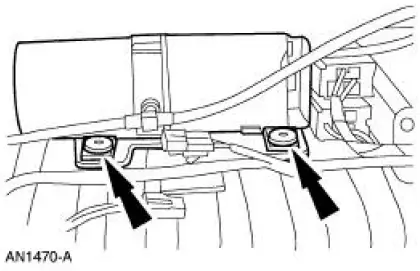

4. Install the motor and cylinders as an assembly.

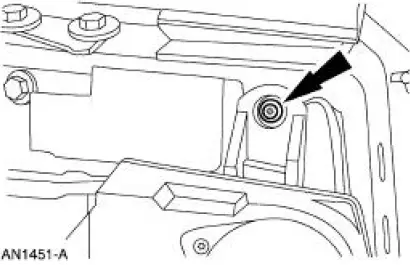

5. Position the motor assembly.

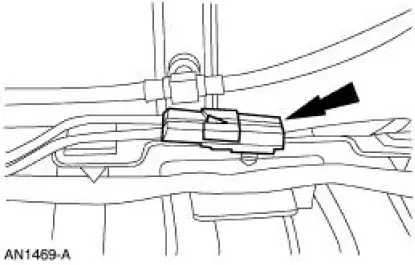

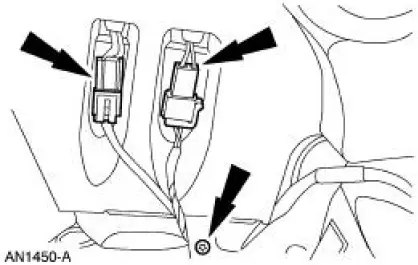

6. Connect the motor electrical connector.

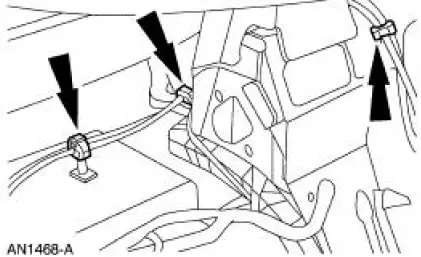

7. Engage the hydraulic line retainers on each side.

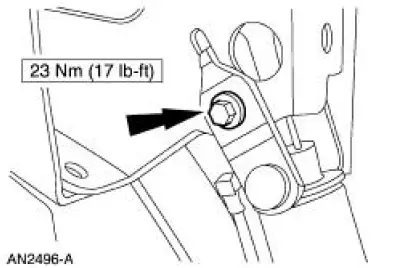

8. Position the lift cylinders and install the nuts.

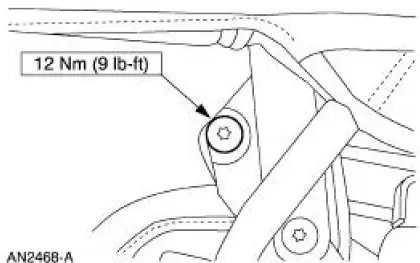

9. Install the two cylinder rod mounting bolts.

10. Install the speakers.

11. Install the screws.

12. NOTE: This step applies to vehicles equipped with the Mach sound system.

Install the screw and connect the electrical connectors.

13. Install the rear quarter trim panel. For additional information, refer to Section.

14. Latch the convertible top.

Removal

Removal

NOTE: The convertible top hydraulic components are removed from the vehicle

as an assembly. The

hydraulic components are individually repaired and the system must be bled

before being installed into ...

Bumpers

Bumpers

Torque Specifications

Bumpers

CAUTION: Never apply excessive heat to the bumper cover surface. Heat

could cause

distortion of the bumper cover.

The bumper systems consist of the following components ...

Other materials:

Adjusting the headlamps

The headlamps on your vehicle are properly aimed at the assembly plant.

If your vehicle has been in an accident, an authorized dealer should

check the alignment of your headlamps.

Vertical Aim Adjustment

1. Park the vehicle directly in front of a wall or scre ...

Body Closures

General Specifications

Torque Specifications

Body Closures

The body closures consist of the following components:

door checks

front door

front door latch strikers

front door hinges

front door opening weatherstrips

hood

hood (Cobra) ...

Cleaning the alloy wheels

Note: Do not use chrome cleaner, metal cleaner or polish on wheels and

wheel covers.

A clearcoat paint finish coats aluminum wheels and wheel covers.

In order to maintain their condition:

• Clean weekly with Motorcraft Wheel and Tire Cleaner. Use a sponge ...