Ford Mustang (1999-2004) Service Manual: Removal

NOTE: The convertible top hydraulic components are removed from the vehicle as an assembly. The hydraulic components are individually repaired and the system must be bled before being installed into the vehicle.

Hydraulic system

1. Unlatch the convertible top.

2. Remove the rear quarter trim panel. For additional information, refer to Section.

3. NOTE: This step applies to vehicles equipped with the Mach sound system.

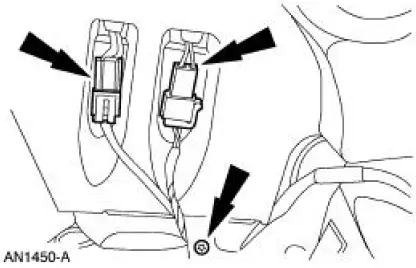

Remove the screw and disconnect the electrical connectors.

4. Remove the screws.

5. Remove the speakers.

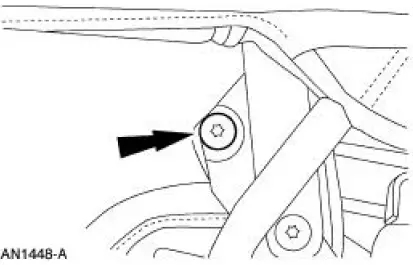

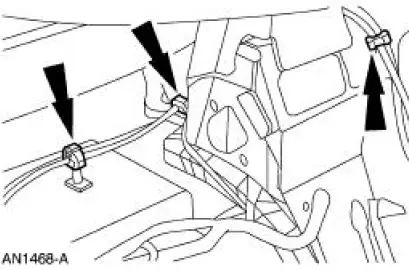

6. Remove the two cylinder rod mounting bolts.

7. Fully lower the lift cylinders.

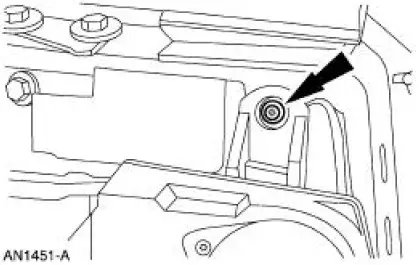

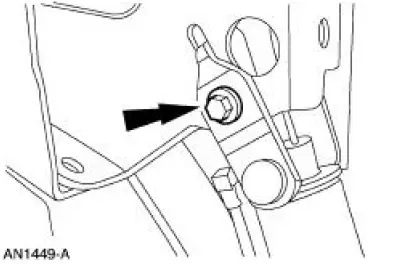

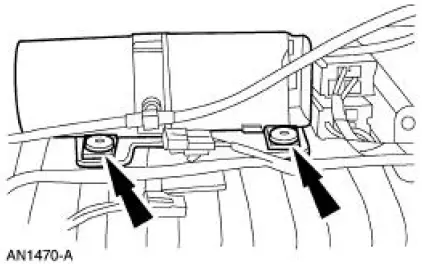

8. Remove the nuts and the lift cylinders.

9. Release the hydraulic line retainers on each side.

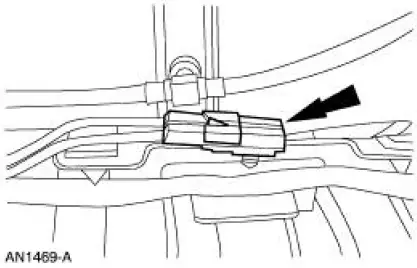

10. Disconnect the motor electrical connector.

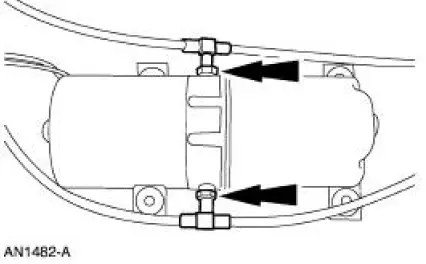

11. Pull up on the motor to release the rubber retainers.

12. Remove the motor and cylinders as an assembly.

Lift cylinder

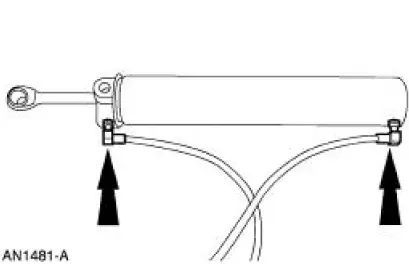

13. NOTE: Prior to their removal, mark the upper and lower hydraulic lines to insure correct installation on the new cylinder.

Remove the hydraulic lines from the cylinder.

Motor assembly

14. NOTE: Prior to removal, mark the hydraulic lines to insure correct installation of the motor assembly.

Remove the hydraulic lines from the motor assembly.

Installation

Installation

Lift cylinder

1. NOTE: Be sure that each fitting is installed in the correct position on

the folding top hydraulic

component.

NOTE: Make sure that the tetra seal is installed in the bottom of each of ...

Other materials:

Assembly

1. Install the locking lever cam and pin.

2. Install the lock actuator lever and pin.

3. Install the lock actuator lever return spring.

4. Install the ignition lock cylinder lockout lever.

5. NOTE: The lock lever with two teeth is installed on the left ...

Installation

1. CAUTION: To prevent refrigerant system contamination, do not allow

dirt or other

foreign materials to enter the A/C compressor.

Clean the A/C compressor nose area.

2. Place the shaft seal on the special tool. Lubricate the shaft seal and the

special tool ...

Output Shaft

Special Tool(s)

Puller, Bearing

205-D064 (D84L-1123-A)

Adapter for 303-224 (Handle)

205-153 (T80T-4000-W)

Installer, Output Shaft Rear

Bearing

308-401

Remover/Installer, Bearing

Tube

308-025 (T75L-7025 ...