Ford Mustang (1999-2004) Service Manual: Installation

1. CAUTION: The timing chain procedures must be followed exactly or damage to the valve and pistons will result.

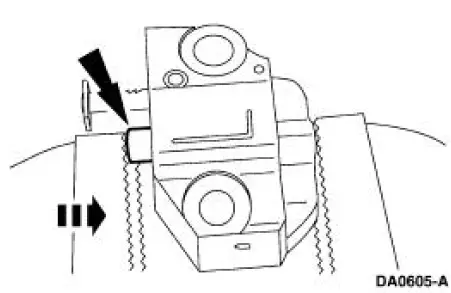

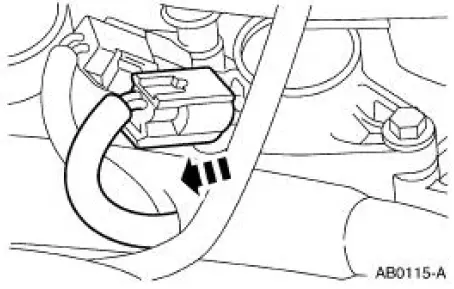

Compress the tensioner plunger, using an edge of a vise.

2. While holding the ratchet mechanism, push the ratchet arm back into the tensioner housing.

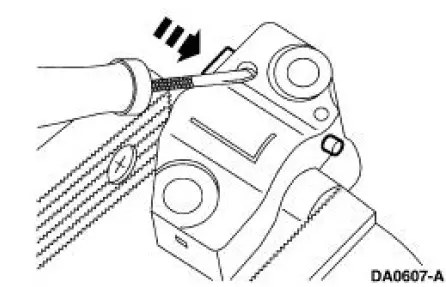

3. Install a paper clip into the hole in the tensioner housing to hold the ratchet assembly and plunger in during installation.

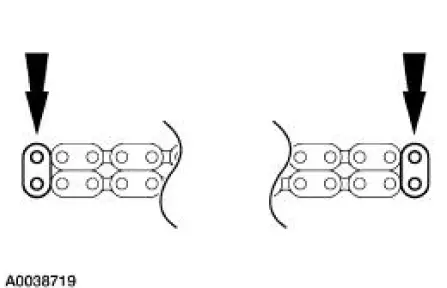

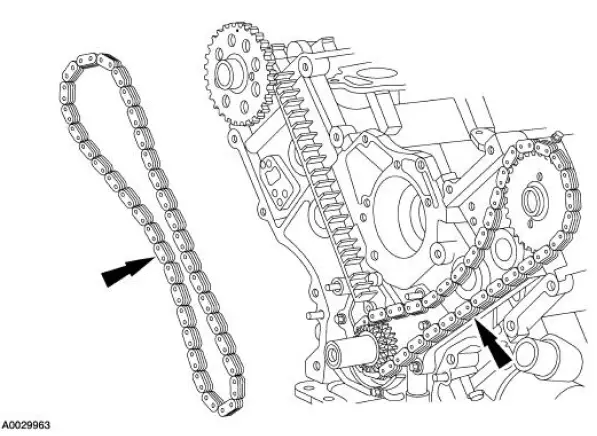

4. If the copper links are not visible, mark one link on one end and one link on the other end, and use as timing marks.

5. Install the camshaft sprockets and new bolts. Tighten the bolts in two stages.

- Stage 1: Tighten the bolt to 40 Nm (30 lb-ft).

- Stage 2: Tighten the bolt an additional 90 degrees (1/4 turn).

6. Remove the special tool.

7. Using the special tool, position the crankshaft so the number one cylinder is at TDC.

8. Remove the special tool.

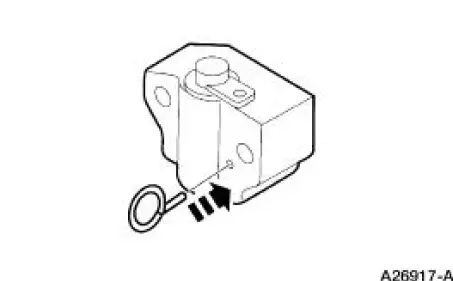

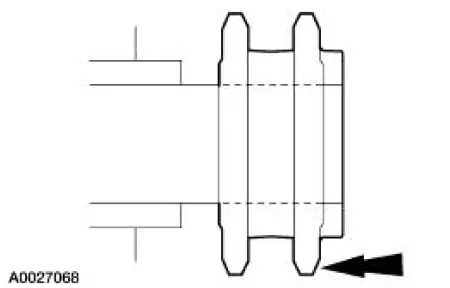

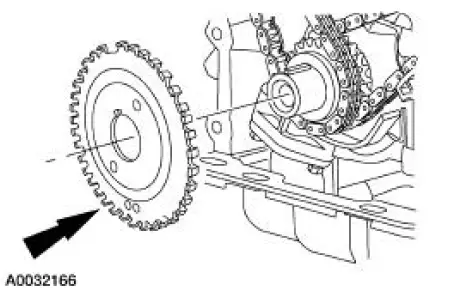

9. Install the crankshaft sprocket, making sure the flange faces forward.

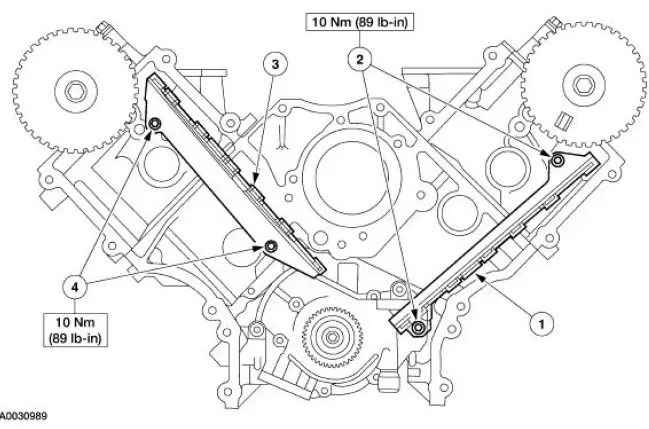

10. Install the timing chain guide.

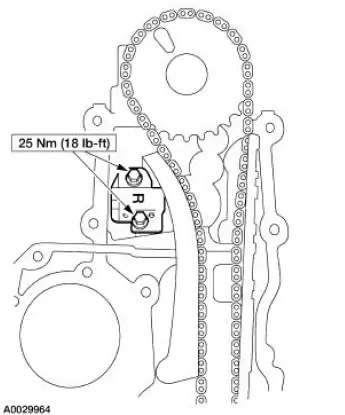

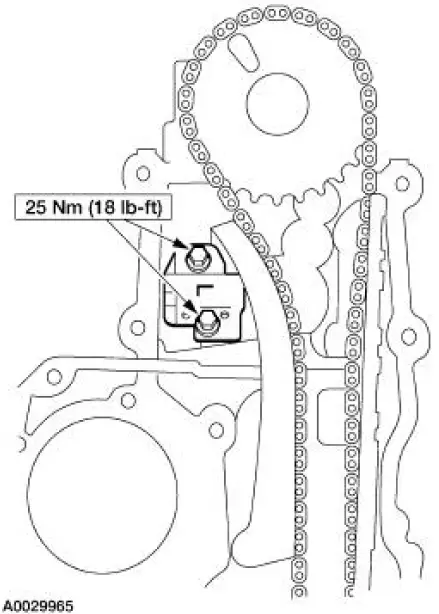

1. Position the LH timing chain guide.

2. Install and tighten the LH bolts.

3. Position the RH timing chain guide.

4. Install and tighten the RH bolts.

11. Install the timing chains.

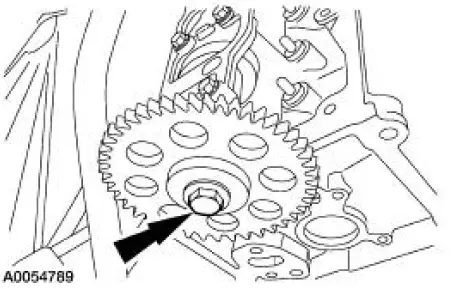

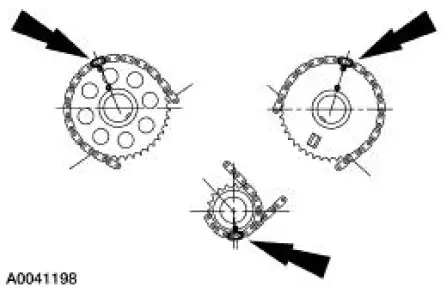

- Install the LH (inner) timing chain on the crankshaft sprocket, aligning the copper link with the dot on the crankshaft sprocket.

- Install the LH (inner) timing chain on the camshaft sprocket, aligning the copper link with the dot on the camshaft sprocket.

- Install the RH (outer) timing chain on the crankshaft sprocket, aligning the copper link with the dot on the crankshaft sprocket.

- Install the RH (outer) timing chain on the camshaft sprocket, aligning the copper link with the dot on the camshaft sprocket.

12. Make sure that the copper (marked) chain links are lined up with the dots on the crankshaft sprocket and the camshaft sprockets.

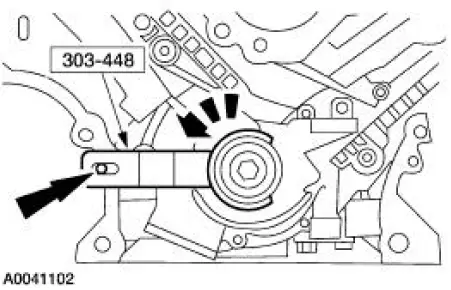

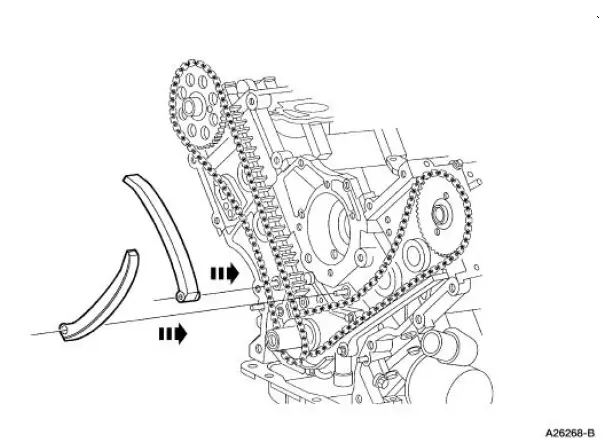

13. NOTE: The LH timing chain tensioner arm has a bump near the dowel hole, for identification.

Position the LH and the RH timing chain tensioner arm on the dowel pins.

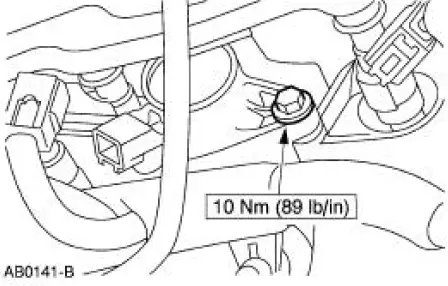

14. Position the RH timing chain tensioner and install the bolts.

15. Position the LH timing chain tensioner and install the bolts.

16. Remove the paper clip from the RH and the LH timing chain tensioners.

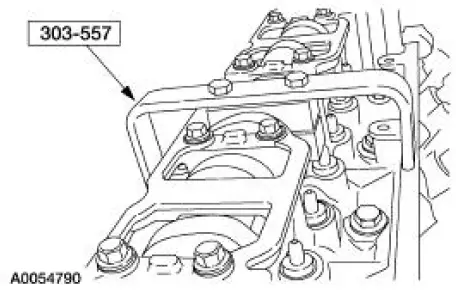

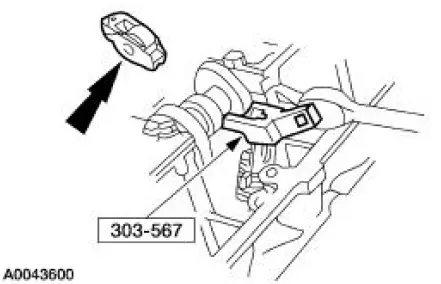

17. NOTE: Rotate the camshaft to the base circle of the camshaft lobe before installing the roller followers.

NOTE: Keep all the roller followers in order when installing.

Using the special tool, install the 16 roller followers.

18. Install the eight spark plugs.

19. Install the eight ignition coils and bolts.

20. Connect the eight ignition coil electrical connectors.

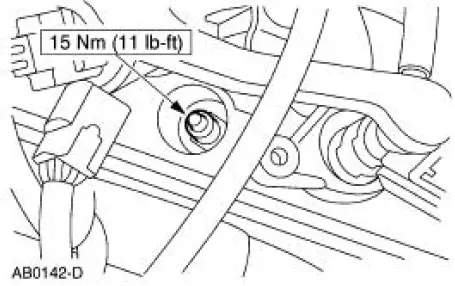

21. Install the crankshaft sensor ring on the crankshaft.

22. Install the engine front cover. For additional information, refer to Engine Front Cover in this section.

Removal

Removal

CAUTION: Since the engine is not free-wheeling, timing procedures must

be followed

exactly or piston and valve damage can occur.

1. Remove the engine front cover. For additional information, refer to ...

Valve Seals

Valve Seals

Special Tool(s)

Valve Spring Compressor

303-452 (T93P-6565-AR)

Valve Stem Seal Replacer

303-383 (T91P-6571-A)

Compressor, Valve Spring

(Exhaust)

303-567 (T97 ...

Other materials:

Removal

1. Use a suitable suction device to lower the brake fluid level in

the master cylinder reservoir.

2. Raise and support the vehicle.

3. Remove the wheel and tire assembly.

4. Inspect the pads for wear or contamination, install new if worn to ...

Pinpoint Tests

PINPOINT TEST A: THE BRAKES PULL OR DRIFT

Test Step

Result / Action to Take

A1 CHECK THE TIRES

YesGO to A2 .

No

CORRECT as necessary.

RETEST for normal

operation.

NOTE: Check tire pressure with the brakes off.

Check tires for u ...

Lamp Assembly - Fog Lamp (GT)

Removal

1. Raise and support the vehicle.

2. Remove the screw.

3. Partially lower the vehicle and remove the fog lamp assembly.

1. Disconnect the electrical connector.

2. Remove the two screws.

3. Remove the fog lamp assembly and replace the bul ...