Ford Mustang (1999-2004) Service Manual: Removal

1. CAUTION: The vehicle must be on level ground and at curb height.

Mark the rear shock absorbers relative to their protective sleeve.

- During installation, raise the suspension to this reference mark before tightening the suspension component fasteners.

2. Raise and support the vehicle.

3. Remove the rear wheel and tire assemblies.

4. Remove the exhaust system.

5. Remove the pinion nose crossmember.

6. CAUTION: Index-mark the driveshaft flange and rear axle pinion flange (4851) to maintain initial balance during installation.

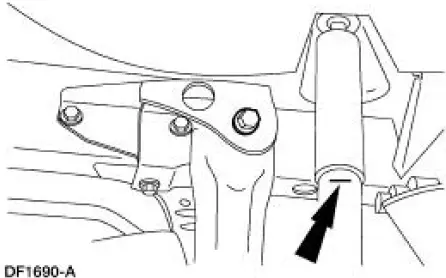

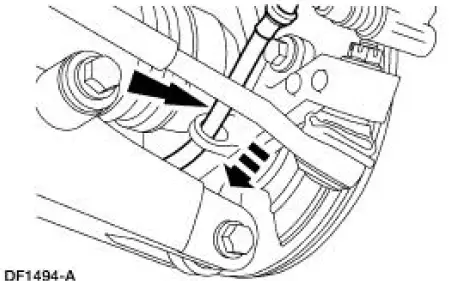

CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. Never hammer on the driveshaft (4602) or any of its components to disconnect the yoke from the flange. Pry only in the area shown, with a suitable tool, to disconnect the yoke from the flange.

Disconnect and position the driveshaft out of the way.

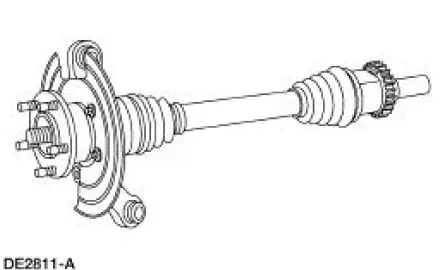

7. NOTE: The following halfshaft and knuckle assembly removal steps apply to both sides of the vehicle.

Disconnect the parking brake cable and conduit from the parking brake lever and the caliper.

8. Separate the parking brake cable and conduit from the knuckle.

9. Remove the rear brake disc.

- Remove the rear brake caliper and support bracket from the knuckle as an

assembly.

Wire the caliper and support bracket assembly out of the way.

10. Remove the rear brake anti-lock sensor and position it aside.

11. Support the lower suspension arm and bushing with a jack stand.

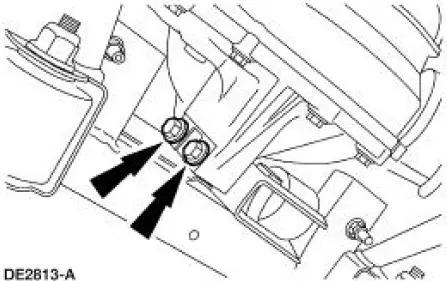

12. Remove and discard the nut and bolt.

13. Remove and discard the cotter pin and nut.

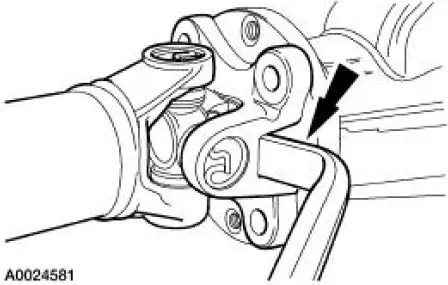

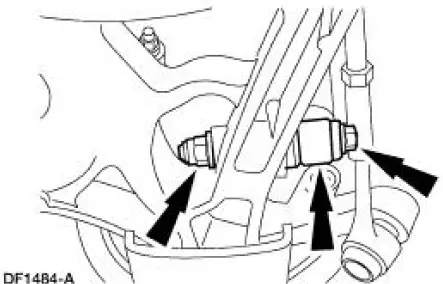

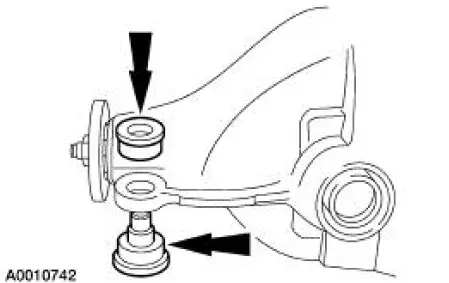

14. CAUTION: Do not strike the toe link or the knuckle to disconnect the toe link from the knuckle.

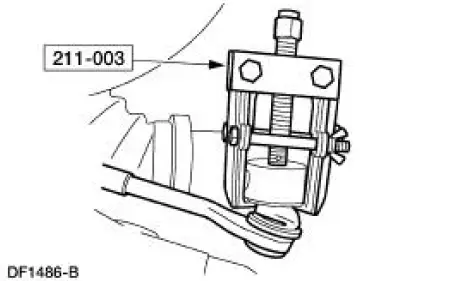

Using the special tool, disconnect the toe link from the knuckle.

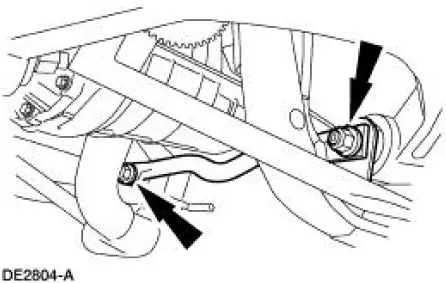

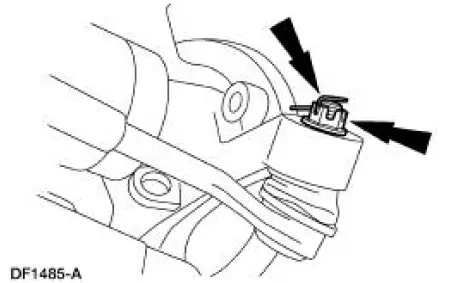

15. Mark the cam bolt position relative to the upper suspension arm and bushing.

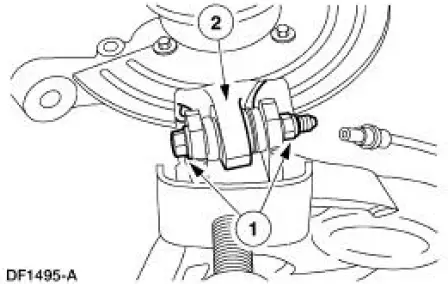

16. Disconnect the knuckle from the lower suspension arm and bushing.

1. Remove and discard the nut and bolt.

2. Disconnect the knuckle from the lower suspension arm and bushing.

17. NOTE: Mark the new cam bolt in the same position as the old one for assembly reference before discarding the old bolt.

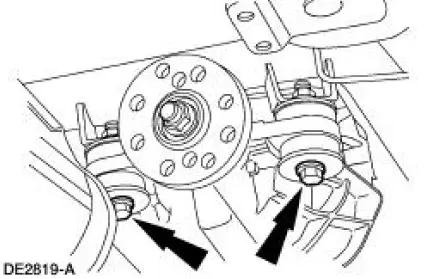

Disconnect the knuckle from upper suspension arm and bushing.

1. Remove and discard the nut and bolt.

2. Disconnect the knuckle from the upper suspension arm and bushing.

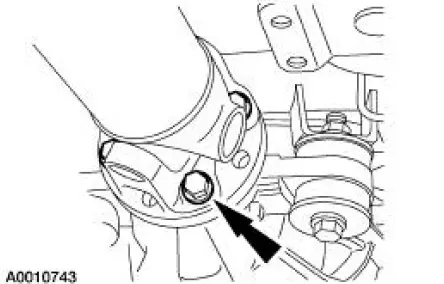

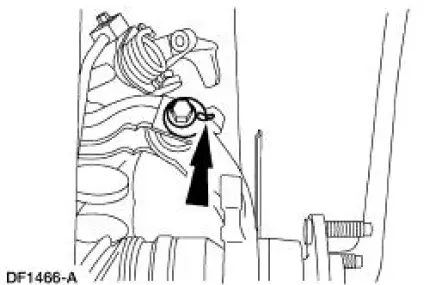

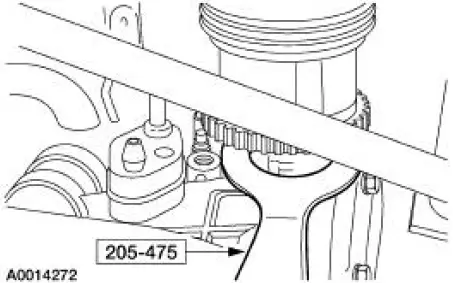

18. CAUTION: The crown on the tool forks must face away from the differential housing. Position the special tool correctly between the CV joint and the differential housing so as not to damage the differential seal.

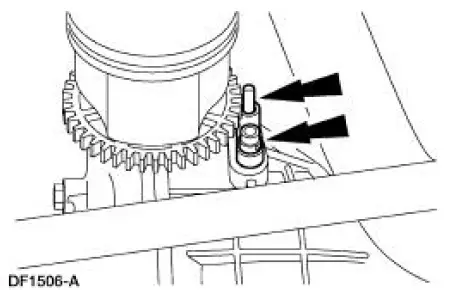

Using the special tool, exert enough pressure to overcome the circlip and separate the CV joint from the differential side gear.

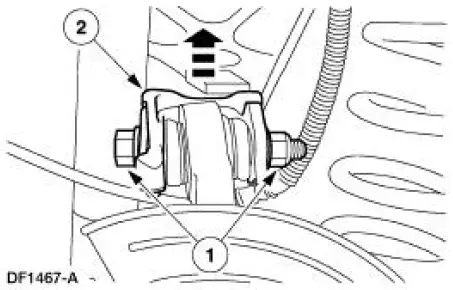

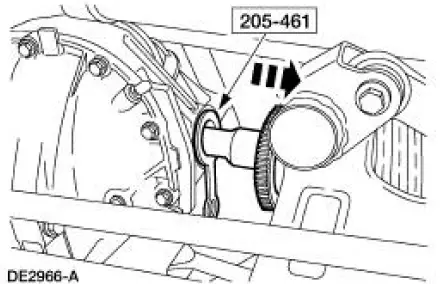

19. Install the special tool.

20. Remove the halfshaft and knuckle assembly from the vehicle.

21. Insert the special tool into the housing bore.

22. Remove the other halfshaft and knuckle assembly as described in the previous steps.

23. Support the differential housing (4010) with a transmission jack.

24. Remove the bolts.

25. Remove the nuts and bolts.

26. CAUTION: Do not damage the axle vent hose. Lower the rear axle assembly from the vehicle.

27. If removal of the mounting bushings is necessary, remove them by hand.

Axle Housing

Axle Housing

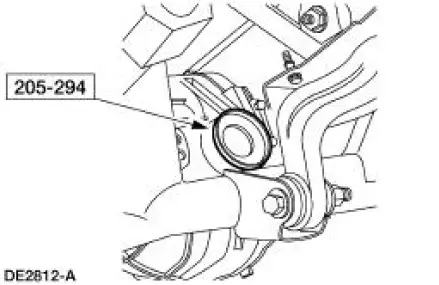

Special Tool(s)

Plug Set, Differential

205-294 (T89P-4850-B)

Protector, Differential Seal

(Pair)

205-461

Remover, Halfshaft

205-475

Remover, Steering Arm

2 ...

Installation

Installation

1. Install the bushings, if removed.

2. Using the transmission jack, raise the rear axle assembly into position.

3. Install the bolts and nuts.

4. Install the bolts.

5. CAUTION: Align the index ...

Other materials:

Getting the services you need

Warranty repairs to your vehicle must be performed by an authorized

dealer. While any authorized dealer handling your vehicle line will

provide warranty service, we recommend you return to your selling

authorized dealer who wants to ensure your continued satis ...

Instrument Panel - Center Finish Panel

Removal and Installation

All vehicles

1. Disconnect the battery ground cable. For additional information,

refer to Section.

Vehicles with automatic transmission

2. Place the selector lever in the 1 position.

Vehicles with manual transmission

3. ...

Cooling Fan Motor and Shroud

Removal and Installation

1. Disconnect the battery ground cable.

2. Remove the degas bottle or coolant expansion tank. For additional

information, refer to Degas

Bottle-4.6L(2V) and 4.6L(4V) in this section.

3. Disconnect the cooling fan electrical connecto ...