Ford Mustang (1999-2004) Service Manual: Removal

CAUTION: Since the engine is not free-wheeling, if the crankshaft or the camshafts are moved in any manner during removal and installation, the crankshaft and the camshafts must be re-synchronized.

1. Remove the engine front cover. For additional information, refer to Engine Front Cover in this section.

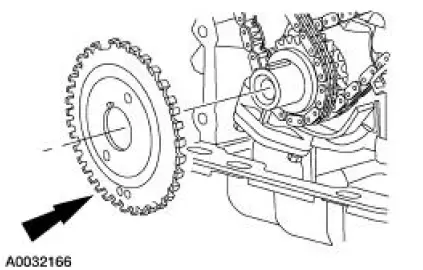

2. Remove the crankshaft sensor ring from the crankshaft.

3. CAUTION: Unless otherwise instructed, at no time when the timing chains are removed and the cylinder heads are installed is the crankshaft or the camshaft to be rotated. Severe piston and valve damage will occur.

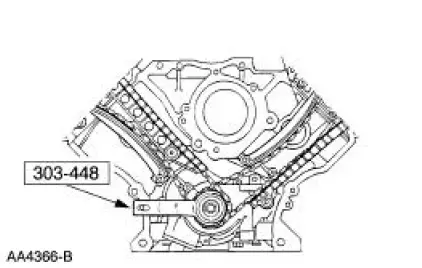

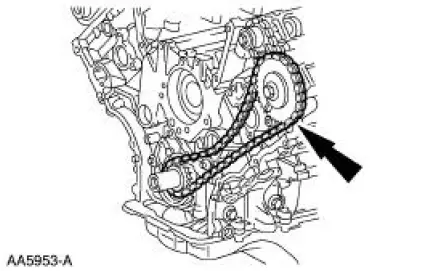

Using the special tool, position the crankshaft as shown.

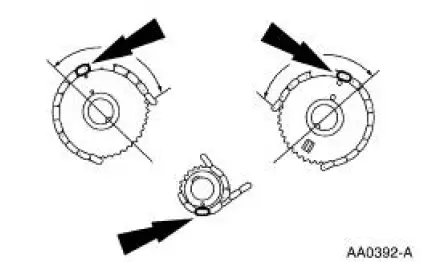

4. CAUTION: The camshaft timing marks must be correctly lined up or damage to the valves and pistons can occur.

NOTE: The copper links on the timing chain may not line up with the timing marks on the sprockets.

Make sure the timing marks on the camshaft sprockets are correctly positioned. If necessary, turn the crankshaft one full turn clockwise to correctly position the sprockets.

5. NOTE: LH shown; RH similar.

Remove the two bolts, the timing chain tensioner and tensioner arm.

6. CAUTION: Unless otherwise instructed, at no time when the timing chains are removed and the cylinder heads are installed is the crankshaft or the camshaft to be rotated. Severe piston and valve damage will occur.

Remove the LH and RH timing chains and the crankshaft sprocket.

Remove the special tool from the crankshaft.

- Remove the RH timing chain from camshaft sprocket.

- Remove the RH timing chain from the crankshaft sprocket.

- Remove the LH timing chain from the camshaft sprocket.

- Remove the LH timing chain and the crankshaft sprocket.

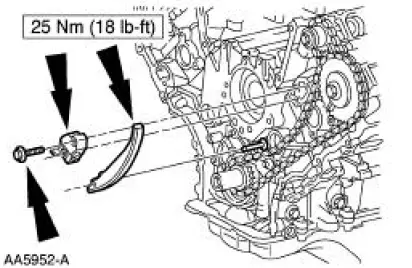

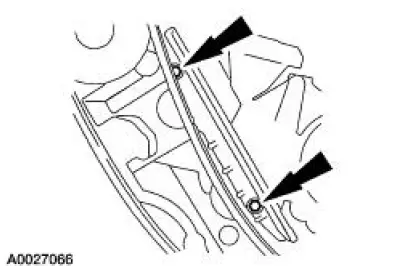

7. CAUTION: The bolts are different lengths and must be returned to their original location.

NOTE: RH shown; LH similar.

Remove the bolts and the timing chain guides.

Timing Drive Components

Timing Drive Components

Special Tool(s)

Holding Tool, Crankshaft

303-448 (T93P-6303-A)

...

Installation

Installation

1. CAUTION: Timing chain procedures must be followed exactly or damage

to the

pistons or valves will result.

Compress the tensioner plunger, using a soft-jawed vise.

2. Install a retaining clip on ...

Other materials:

Output State Control (OSC) Mode

Output State Control (OSC) allows the technician to take control of

certain parameters to function the

transmission. For example, OSC allows the technician to shift the

transmission only when he/she

commands a gear change. If the technician commands ...

Clearing all MyKeys

You can clear all MyKeys within the same key cycle as you created the

MyKey. If you switch your ignition off, however, you will need to use an

admin key to clear your MyKeys.

Note: When you clear your MyKeys, you remove all restrictions and

return all MyKeys ...

Headliner

Removal

1. Remove the two upper quarter panels. For additional information,

refer to Trim Panel-Upper

Quarter in this section.

2. Remove the two windshield side garnish mouldings.

3. Remove the two sun visors.

1. Remove the six screws.

2. ...