Ford Mustang (1999-2004) Service Manual: Rocker Arms - Inspection

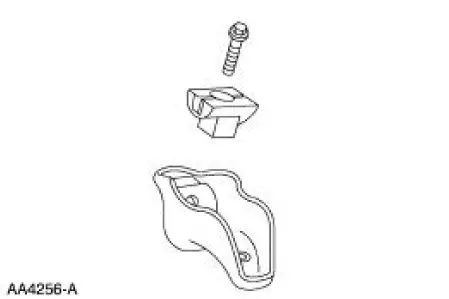

CAUTION: Do not attempt to true surfaces by grinding. Check the rocker arm pad, side rails and seat for excessive wear, cracks, nicks or burrs. Check the rocker arm seat bolt for stripped or broken threads. Install new components as ncessary or possible damage may occur.

1. Inspect the rocker arm push rod bore for nicks, scratches, scores or scuffs. Install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

2. Inspect the pad at the valve end of the rocker arm for indications of scuffing or abnormal wear. If the pad is grooved, install a new rocker arm. Refer to the appropriate section in Group 303 for the procedure.

Push Rods - Cleaning

1. Clean the push rods (6565) in a suitable solvent. Blow out the oil passage in the push rods with compressed air.

Sprockets

Sprockets

1. WARNING: To avoid the possibility of personal injury or damage

to the vehicle, do

not operate the engine with the hood open until the fan blade has been

examined for

possible cracks and separ ...

Push Rods - Inspection

Push Rods - Inspection

1. CAUTION: Do not attempt to straighten push rods.

Check the ends of the push rods for nicks, grooves, roughness or

excessive wear. Install new

push rods as necessary. Refer to the appropriate se ...

Other materials:

Navigation system

Your navigation system allows you to set a destination by using your

touchscreen or voice commands.

The navigation system contains map coverage for the United States,

Puerto Rico and U.S. Virgin Islands, Canada and Mexico.

Disclaimer

A disclaimer appears onc ...

Installation

1. Install the bushings, if removed.

2. Using the transmission jack, raise the rear axle assembly into position.

3. Install the bolts and nuts.

4. Install the bolts.

5. CAUTION: Align the index-marks.

CAUTION: Install the driveshaft with new bolts. If ...

Removal

1. Raise and support the vehicle.

2. Remove the wheel and tire assembly.

3. WARNING: Brake fluid contains polyglycol ethers and polyglycols.

Avoid contact

with eyes. Wash hands thoroughly after handling. If brake fluid contacts

eyes, flush eyes ...