Ford Mustang (1999-2004) Service Manual: Sprockets

1. WARNING: To avoid the possibility of personal injury or damage to the vehicle, do not operate the engine with the hood open until the fan blade has been examined for possible cracks and separation.

NOTE: Specifications show the expected minimum or maximum condition. Refer to the appropriate section in Group 303 for the procedure.

NOTE: If a component fails to meet the specifications, it is necessary to install a new component or refinish. If the component can be refinished, wear limits are provided as an aid to making a decision. A new component must be installed for any component that fails to meet specifications and cannot be refinished.

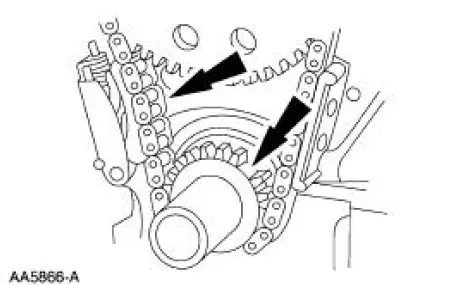

Inspect the timing chain/belt and the sprockets.

- Install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Rocker Arms - Cleaning

1. Clean all parts thoroughly. Make sure all oil passages are open.

2. Make sure oil passage in the push rod/valve tappet end of the rocker arm (6564) is open.

Component Tests

Component Tests

Engine Oil Leaks

NOTE: When diagnosing engine oil leaks, the source and location of

the leak must be positively

identified prior to repair.

Prior to carrying out this procedure, clean all sealin ...

Rocker Arms - Inspection

Rocker Arms - Inspection

CAUTION: Do not attempt to true surfaces by grinding. Check the

rocker arm pad, side

rails and seat for excessive wear, cracks, nicks or burrs. Check the rocker

arm seat bolt for

stripped or bro ...

Other materials:

Closing the convertible top

Note: The convertible top will not operate unless the vehicle is

stationary or traveling under 3 mph (5 kmh).

Note: Make sure that the latch handles are pulled down and in the fully

opened position before the top makes contact with the windshield

header. This ...

Torque Converter End Play Check

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

End Play Gauge, Torque

Converter

307-071 (T80L-7902-A) or

equivalent

1. Install the special tool into the torque converter pump ...

Final disassembly

32. If not done previously, remove the bolts.

33. CAUTION: Do not damage the bolt hole threads.

If not done previously, insert a punch in the bolt holes and drive off the

differential ring gear.

34. Using the special tools, remove the differential bearin ...