Ford Mustang (1999-2004) Service Manual: Exhaust Manifold - Inspection

Special Tool(s)

|

|

Straight Edge 303-D039 (D83L-4201-A) or equivalent |

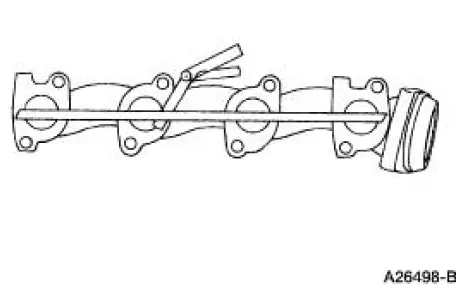

1. Place a straight edge across the exhaust manifold flanges and check for warping with a feeler gauge.

Bearing -Inspection

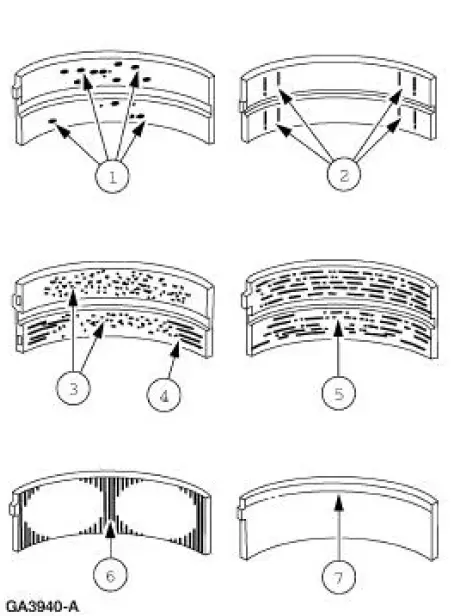

1. Inspect bearings for the following defects. Possible causes are shown:

1. Cratering - fatigue failure.

2. Spot polishing - incorrect seating.

3. Imbedded dirt engine oil.

4. Scratching - dirty engine oil.

5. Base exposed - poor lubrication.

6. Both edges worn - journal damaged.

7. One edge worn - journal tapered or bearing not seated.

Spark Plug - Inspection

Spark Plug - Inspection

1. Inspect the spark plug for a bridged gap.

Check for deposit build-up closing the gap between the electrodes.

Deposits are caused

by oil or carbon fouling.

Clean the spark plug.

2. Ch ...

Engine - 3.8L

Engine - 3.8L

General Specifications

a - 20-200 seconds to leakdown 3.18 mm (0.125 in) with 225 Newtons (50

pounds) load and tappet filled

with leak-down fluid.

Torque Specifications

a - Refer to th ...

Other materials:

Lock Cylinder - Door

Removal

1. NOTE: Individual lock cylinders are repaired by discarding the

inoperative cylinder and building

a new lock cylinder using the appropriate lock repair package. The lock

repair package includes

a detailed instruction sheet to build the ne ...

Output Shaft

Special Tool(s)

Remover, Drive Pinion Bearing

Cone

205-D002 (D79L-4621-A) or

equivalent

Installer, Drive Pinion Bearing

Cone

205-011 (T57L-4621-B)

...

Catalyst Monitor Sensor

Special Tool(s)

Socket, Exhaust Gas Oxygen

Sensor

303-476 (T94P-9472-A)

Material

Item

Specification

Penetrating and Lock Lubricant

or equivalent

E8AZ-19A501-

B

Removal and Installation

1. Disconnect the battery ground ...