Ford Mustang (1999-2004) Service Manual: Spring Codes

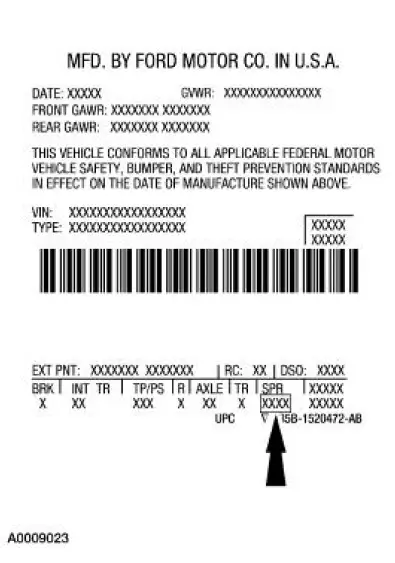

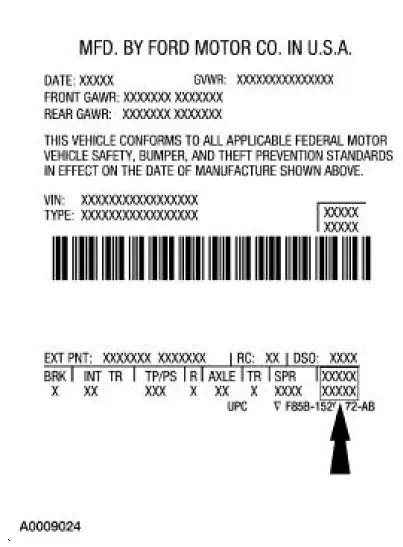

The spring code portion of the vehicle certification (VC) label identifies both the front and rear springs.

The first letter/number indicates the front spring code. The second letter/number indicates the rear spring code.

- Front springs - base part number - 5310 (RH/LH)

- Rear springs - base part number - 5560 (RH/LH)

Powertrain Calibration Information

NOTE: Powertrain calibration information is limited to a maximum of five characters per line on the Vehicle Certification Label. Because of this, calibration identification consisting of more than five characters will wrap to the second line on the VC label.

Powertrain calibration information is printed in the lower right corner of the Vehicle Certification Label.

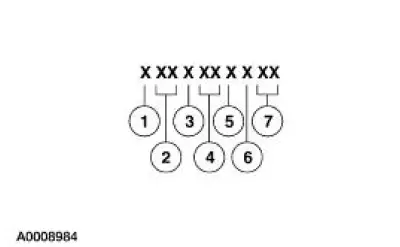

Only the base calibration information is printed. Revision levels will not appear, however, this information can be found in the On Line Automotive Service Information System (OASIS). For the current model year, Ford Motor Company is using three different protocols which describe powertrain base calibration. These protocols are designed to provide worldwide standardization for vehicle calibration. If the electronic calibration strategy has been used since 1998 and carried into the current model year, protocol 1 will be used. Refer to Protocol 1 below. If the electronic calibration strategy has been used since 1999 and is carried into the current model year, protocol 2 will be used. Refer to Protocol 2 below. For new electronic calibration strategies introduced since the 2000 model year, use protocol 3. Refer to Protocol 3 below.

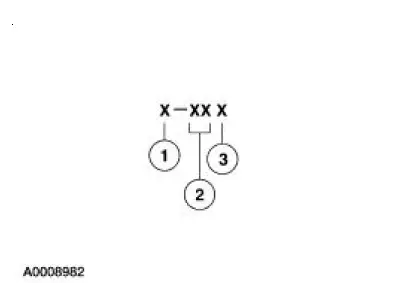

Protocol 1

| Item | Description |

| 1 | Model year (model year in which calibration strategy was first introduced) |

| 2 | Engine code |

| 3 | Engine revision level |

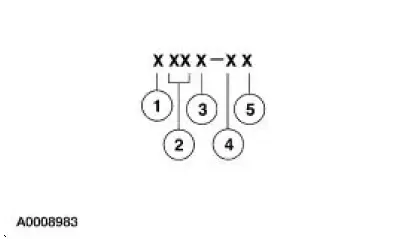

Protocol 2

| Item | Description |

| 1 | Model year (model year in which calibration strategy was first introduced) |

| 2 | Engine code |

| 3 | Transmission code |

| 4 | Emission standard (designates the specific country emission standard) |

| 5 | Design level (design level assigned to the engine) |

Protocol 3

| Item | Description |

| 1 | Model year (model year in which calibration strategy was first introduced) |

| 2 | Vehicle code |

| 3 | Transmission code |

| 4 | Unique calibration (designates different hardware to similar vehicles). Example: tires, drive ratios, etc. |

| 5 | Fleet code (describes fleet to which the vehicle belongs). Example: 6 - evaporative emissions |

| 6 | Certification region (lead region where multiple regions are

included in one calibration). Example: A - U.S. federal |

| 7 | Revision level (will advance as revisions occur). Not printed on label |

Protocol 3

The following offers a more detailed explanation of the coding strategy used for protocol 3.

Model Year

- Y - 2000

- 1 - 2001

- 2 - 2002

- 3 - 2003

Vehicle Line

- ZE - Mustang

Transmission

- 1 - Automatic transmission

- 2 - Manual transmission

Interior Trim Codes

Interior Trim Codes

The interior trim codes are listed below. The first letter/number is for the

interior fabric. The second

letter is for the interior color.

9 - Quantum/Rhodes cloth (base coupe)

A - Link weave cl ...

Unique Calibration

Unique Calibration

The Emissions/CAFE/CO2 Compliance Department is responsible for assigning

these calibration

numbers. Unique calibration identifications are assigned to cover similar

vehicles to differentiate tires, ...

Other materials:

Lock Cylinder - Door

Removal

1. NOTE: Individual lock cylinders are repaired by discarding the

inoperative cylinder and building

a new lock cylinder using the appropriate lock repair package. The lock

repair package includes

a detailed instruction sheet to build the ne ...

Removal

1. Disconnect the battery ground cable. For additional information, refer to

Section.

2. Remove the transmission.

3. Remove the air intake scoop. For additional information, refer to Section.

4. Remove the air cleaner outlet tube. For additional informatio ...

Component Test

Carry out the appropriate Functional Test(s) as determined in Inspection and

Verification.

Functional Test I (Buckle and Tongue)

The safety belt buckle and tongue assembly must operate freely during the

latching and unlatching

function. Fasten the safety bel ...