Ford Mustang (1999-2004) Service Manual: Camshaft Runout

Special Tool(s)

|

|

Dial Indicator Gauge with Holding Fixture 100-002 (TOOL-4201-C) or equivalent |

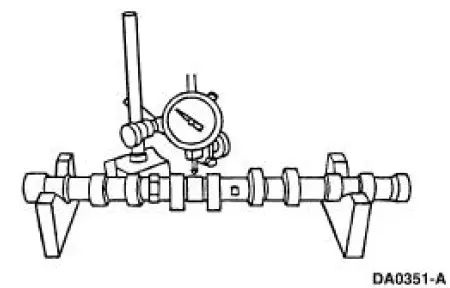

1. NOTE: Camshaft journals must be within specifications before checking runout.

Use a Dial Indicator Gauge with Holding Fixture to measure the camshaft runout.

- Rotate the camshaft and subtract the lowest indicator reading from the highest indicator reading.

- For additional information, refer to the specification chart in the appropriate engine section.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

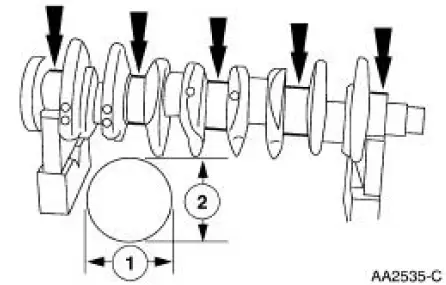

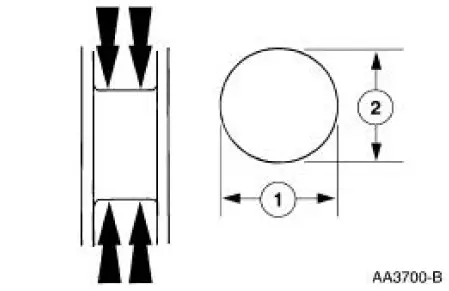

Crankshaft Main Bearing Journal -Diameter

1. Measure each of the crankshaft main bearing journal diameters in at least two directions.

- Refer to the appropriate section in Group 303 for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Crankshaft Main Bearing Journal -Taper

1. Measure each of the crankshaft main bearing journal diameters in at least two directions at each end of the main bearing journal.

- Refer to the appropriate section in Group 303 for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Camshaft Lobe Lift

Camshaft Lobe Lift

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

1. Use a Dial Indicator Gauge with Holding Fixture to measure camshaft

intake/exhaust ...

Crankshaft Main Bearing Journal - Clearance

Crankshaft Main Bearing Journal - Clearance

Special Tool(s)

Plastigage

303-D031 (D81L-6002-B) or

equivalent

NOTE: Crankshaft main bearing journals must be within specifications

before checking journal

clearance.

1. Remove th ...

Other materials:

Door - Air Inlet Duct

Removal

1. Remove the evaporator core housing. For additional information, refer to

Section.

2. Disconnect the vacuum line.

3. Remove the screws and remove the duct.

Installation

1. To install, reverse the removal procedure.

...

Switch - Deactivator

Removal

1. Disconnect the battery ground cable.

2. Remove the deactivator switch.

1. Disconnect the deactivator switch electrical connector.

2. Detach the lower deactivator switch hook.

3. Detach the upper deactivator pivot.

Installation

1. N ...

Inspection and Verification

1. Verify the customer concern by operating the engine to duplicate the

condition.

2. Visually inspect for obvious signs of mechanical damage. Refer to the

following chart.

Visual Inspection Chart

Mechanical

Engine coolant leaks

...