Ford Mustang (1999-2004) Service Manual: Crankshaft Main Bearing Journal - Clearance

Special Tool(s)

|

|

Plastigage 303-D031 (D81L-6002-B) or equivalent |

NOTE: Crankshaft main bearing journals must be within specifications before checking journal clearance.

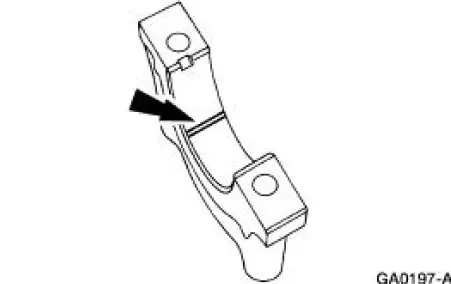

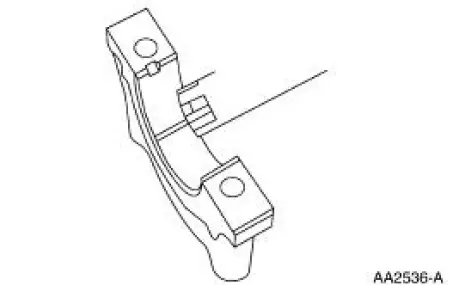

1. Remove the crankshaft main bearing caps and crankshaft main bearing.

2. Lay a piece of Plastigage across the face of each crankshaft main bearing surface.

3. NOTE: Do not turn the crankshaft while carrying out this procedure.

Install and remove the crankshaft main bearing cap.

4. Verify the crankshaft journal clearance.

- Refer to the appropriate section in Group 303 for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Camshaft Runout

Camshaft Runout

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

1. NOTE: Camshaft journals must be within specifications before

checking runout.

Use ...

Crankshaft End Play

Crankshaft End Play

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

1. Measure the crankshaft end play. Use a Dial Indicator Gauge with Holding

Fixture t ...

Other materials:

Ignition Lock Cylinder - Non-Functional

Removal and Installation

1. NOTE: Make sure the front wheels are in the straight-ahead

position.

Disconnect the battery ground cable (14301) and wait at least one minute

to allow the depletion

of the restraint system backup power supply. For addit ...

Removal

1. Remove the differential assembly from the differential housing. For

additional information, refer

to Differential Case in this section.

2. CAUTION: Record the torque necessary to maintain rotation of the drive

pinion gear

through several revolutions prio ...

Changing a fuse

Fuses

WARNING: Always replace a fuse with one that has the

specified amperage rating. Using a fuse with a higher amperage

rating can cause severe wire damage and could start a fire.

If electrical components in your

vehicle are not working, a fuse may

have blo ...