Ford Mustang (1999-2004) Service Manual: Connecting Rod - Side Clearance

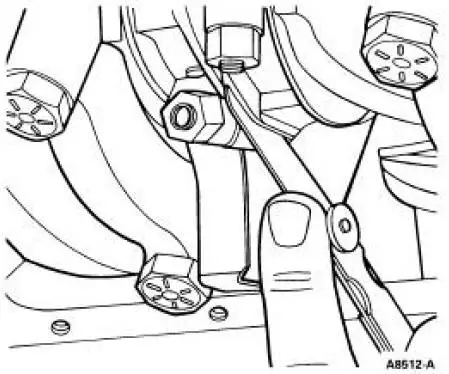

1. Measure the clearance between the connecting rod and the crankshaft. Verify the measurement is within specification.

- Refer to the appropriate section in Group for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group for the procedure.

Roller Follower -Inspection

Push rod engines

1. Inspect the roller for flat spots or scoring. If any damage is found, inspect the camshaft lobes and valve tappet for damage.

OHC engines

Valve Tappet -Inspection

Push rod engines

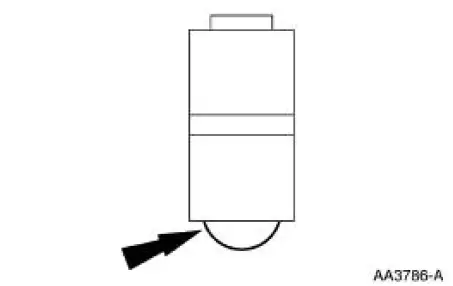

1. Inspect the hydraulic valve tappet and roller for damage. If any damage is found, inspect the camshaft lobes and valves for damage.

OHC engines

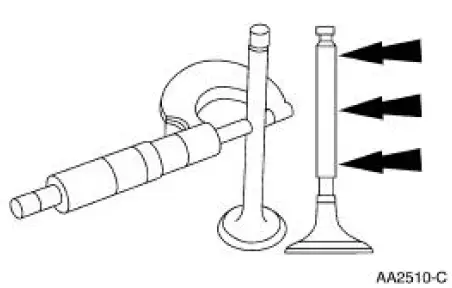

Valve -Stem Diameter

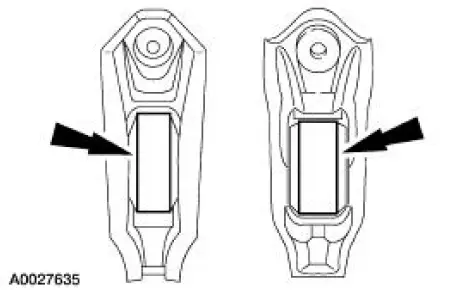

1. Measure the diameter of each intake and exhaust valve stem at the points shown. Verify the diameter is within specification.

- Refer to the appropriate section in Group for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group for the procedure.

Connecting Rod - Bearing Journal Clearance

Connecting Rod - Bearing Journal Clearance

Special Tool(s)

Plastigage

303-D031 (D81L-6002-B) or

equivalent

NOTE: The crankshaft connecting rod journals must be within

specifications to check the connecting

rod bearing journa ...

Valve Stem to Valve Guide Clearance

Valve Stem to Valve Guide Clearance

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Clearance Gauge, Valve Guide

303-004 (TOOL-6505-E) or

equivalent

NOTE: Valve ...

Other materials:

Chuckle

Chuckle that occurs on the coast driving phase is usually caused by excessive

clearance between the

differential gear hub and the differential case bore.

Damage to a gear tooth on the coast side can cause a noise identical to a

chuckle. A very small tooth

n ...

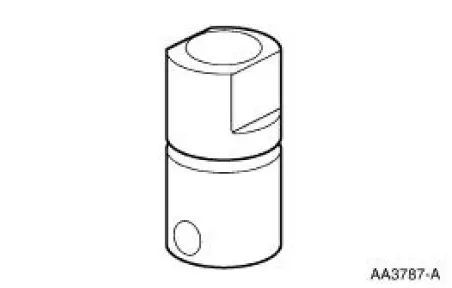

Connecting Rod - Bushing Diameter

1. Measure the inner diameter of the connecting rod bushing, if equipped.

Verify the diameter is

within specification.

Refer to the appropriate section in Group for the procedure.

If out of specification, install new components as necessary. Refer

...

Installation

CAUTION: Electronic modules are sensitive to static electrical

charges. If exposed to

these charges, damage may result.

1. NOTE: Two technicians are necessary to carry out this step.

Install the instrument panel.

2. Install the upper instrument pa ...