Ford Mustang (1999-2004) Service Manual: Disassembly

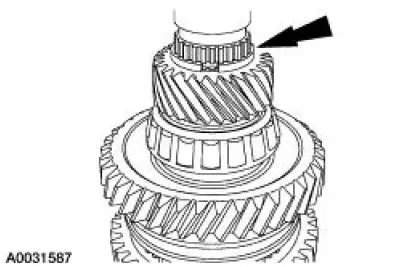

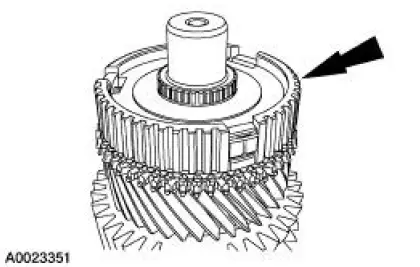

1. Remove the retaining ring above fifth gear.

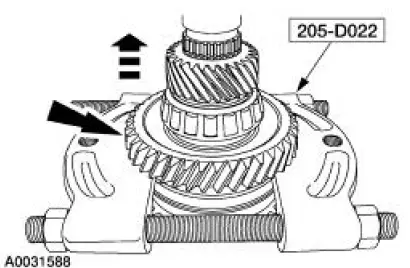

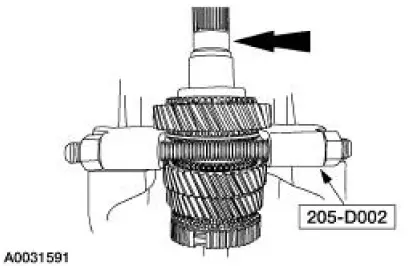

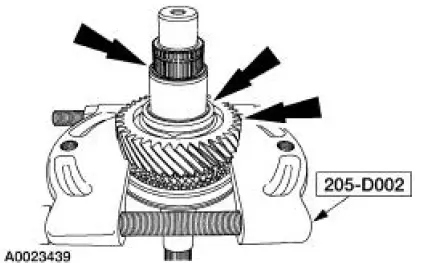

2. CAUTION: Hand tighten the special tool to prevent gear damage.

CAUTION: Support the output shaft while using the press to prevent damage to the shaft or gears.

Using the special tool, press fifth gear, the spacer, the output shaft bearing and reverse gear from the output shaft.

- Discard the output shaft bearing.

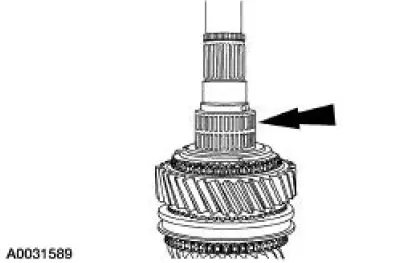

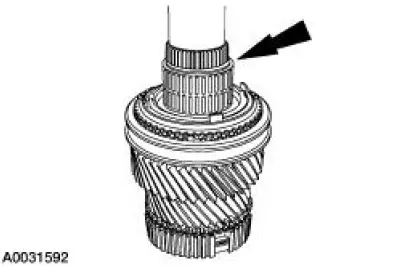

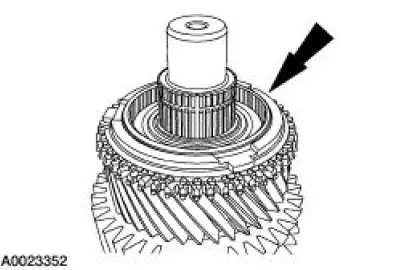

3. Remove reverse gear needle bearing.

- Inspect the needle bearing for wear or damage. Install a new needle bearing as necessary.

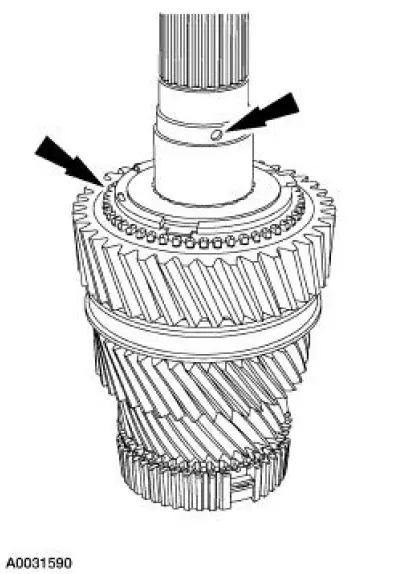

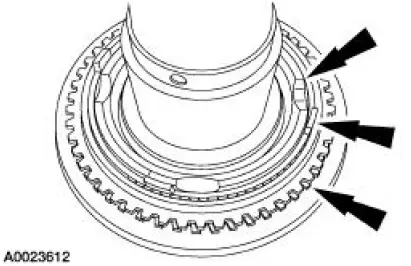

4. Remove the check ball and the blocking ring.

- Inspect the blocking ring for wear or damage. Install new blocking rings as necessary.

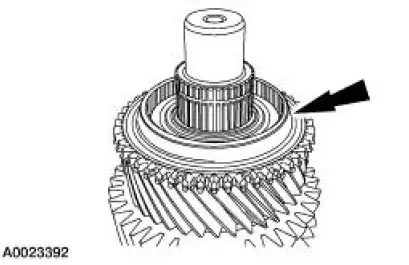

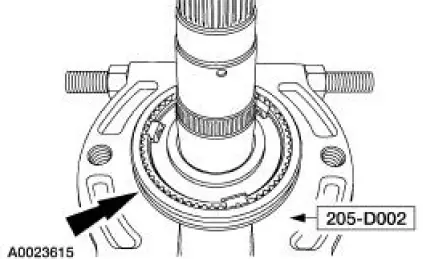

5. NOTE: Install the special tool with the flat side facing first gear.

Using the special tools, press the bearing spacer, the reverse gear synchronizer cone and first gear from the output shaft.

6. Remove the first gear needle bearing.

- Inspect the needle bearing for wear or damage. Install a new needle bearing as necessary.

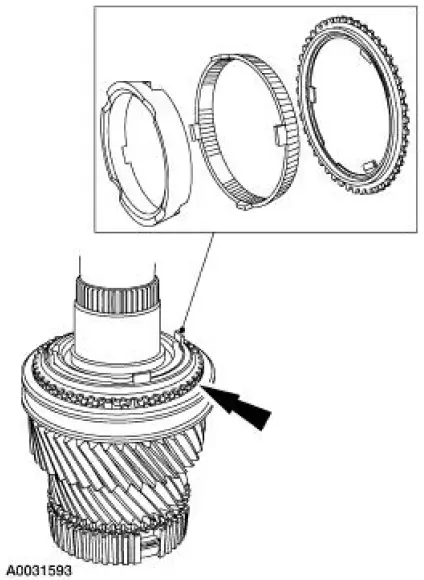

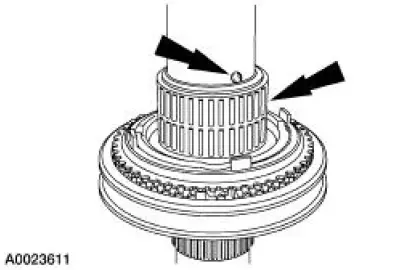

7. Remove the first gear synchronizer inner cone, the first gear synchronizer outer cone and the first gear synchronizer blocking ring.

- Inspect all components for wear or damage. Install new components as necessary.

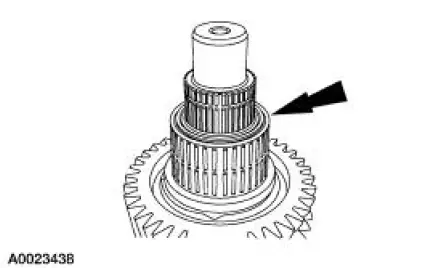

8. NOTE: Reposition the output shaft on the press with the input shaft end facing upward.

- Remove and discard the retaining ring.

9. Remove the third/fourth synchronizer hub.

10. Remove the third/fourth blocking ring.

11. Remove the third gear.

- Inspect the gear for wear or damage. Install a new gear as necessary.

12. Remove the third gear needle bearing.

- Inspect the needle bearing for wear or damage. Install a new needle bearing as necessary.

13. NOTE: Install the special tool behind second gear with the flat side of the tool facing second gear.

Using the special tool, remove the spacer, second gear thrust washer and second gear.

- Inspect the gear for wear or damage. Install a new gear as necessary.

14. Remove the check ball and second gear needle bearing.

- Inspect the needle bearing for wear or damage. Install a new needle bearing as necessary.

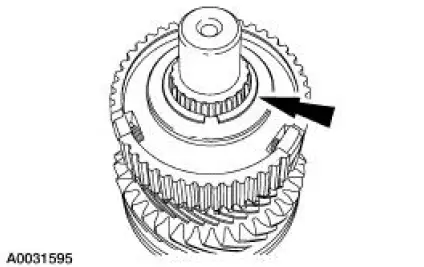

15. Remove the second gear synchronizer inner cone, second gear synchronizer outer cone and the second gear synchronizer blocking ring.

- Inspect all components for wear or damage. Install new components as necessary.

16. Remove the snap ring, then using the special tool, press off the first/second gear synchronizer.

Output Shaft

Output Shaft

Special Tool(s)

Remover, Drive Pinion Bearing

Cone

205-D002 (D79L-4621-A) or

equivalent

Installer, Drive Pinion Bearing

Cone

205-011 (T57L-4621-B)

...

Assembly

Assembly

1. Carry out the following before reassembling:

Inspect the gears for broken or cracked teeth. Check for unusual wear

patterns.

Inspect the thrust washers for face wear, cracks, scoring and for s ...

Other materials:

Accelerator Cable - 3.8L

Removal and Installation

1. Push the accelerator cable nylon bushing out of the accelerator pedal and

shaft arm.

2. Remove the bolts retaining the accelerator cable to the dash panel.

3. Disconnect the accelerator cable from the throttle body by rotating ...

Fill

1. WARNING: Do not mix oil types, any mixture or any unapproved oil can

lead to seal

deterioration and leaks. A leak can ultimately cause loss of fluid, which can

result in a

loss of power steering assist.

Check the fluid level. If necessary, fill the reserv ...

Refrigerant Oil Adding

CAUTION: During normal A/C operation, oil is circulated through the

system with the

refrigerant, and a small amount is retained in each component. If certain

components of the

system are removed for new installation, some of the refrigerant oil will go

with ...